Construction method for permanently protecting existing pipeline during road reconstruction

A construction method and pipeline protection technology, applied in the direction of the road floor, buildings, etc., can solve the problems of large structural size, increased force on the cover plate, structural safety and impact on project cost, so as to save project cost and avoid disturbance , Reduce the effect of span and culvert backfill materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

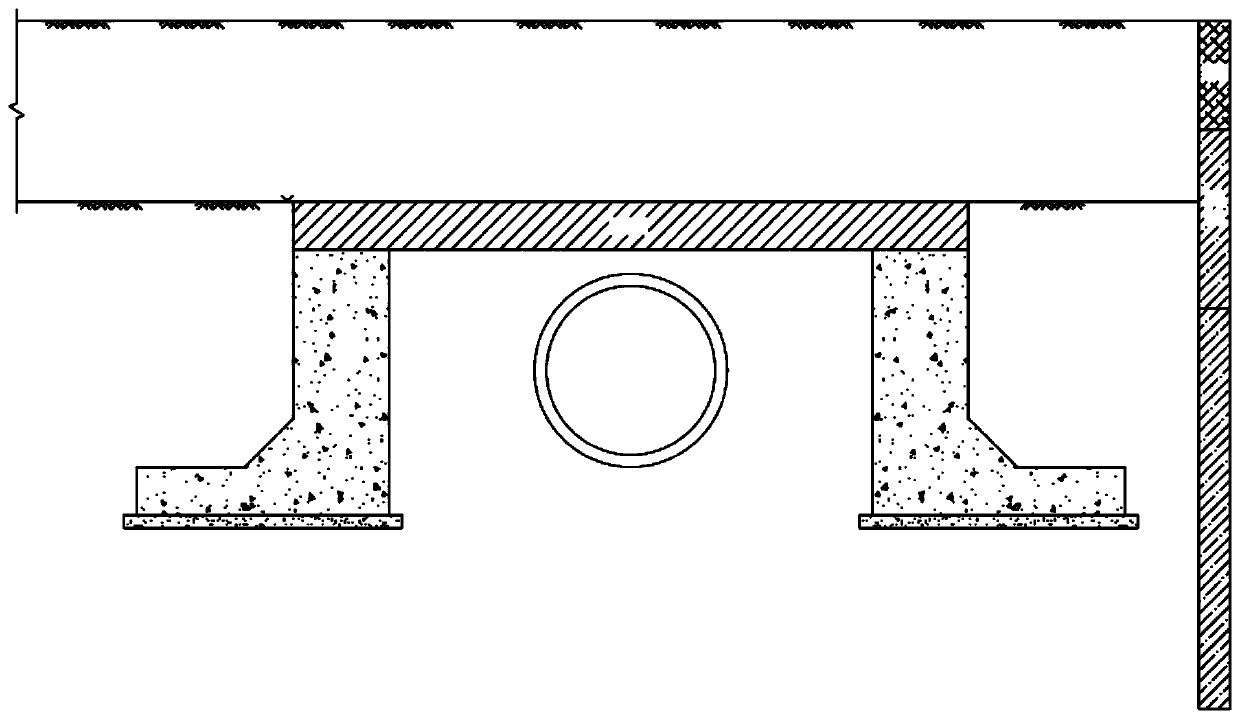

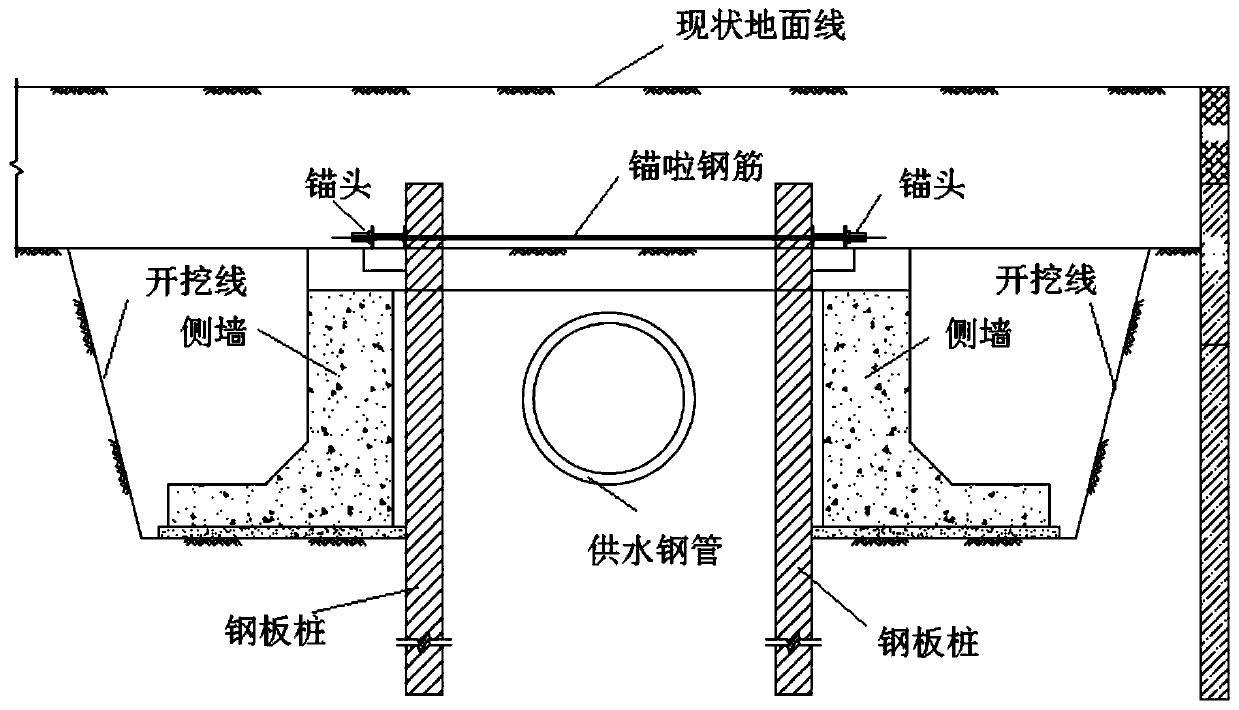

[0022] Such as Figure 2 to Figure 4 As shown, the construction method for permanent protection of existing pipelines during road reconstruction, the specific steps are as follows:

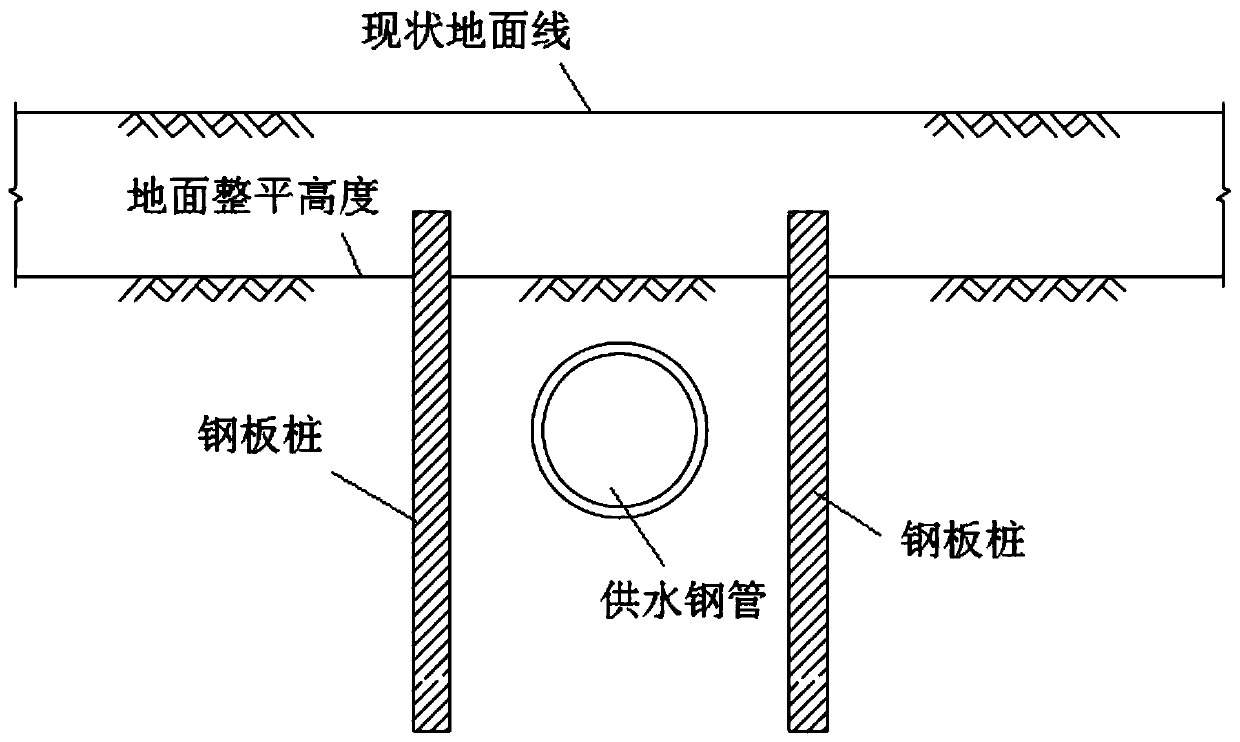

[0023] Step 1. According to the pipeline position of the water supply steel pipe, stake out on the spot, remove the hard layer of the road surface structure, and insert and drive steel sheet piles on both sides of the water supply steel pipe along the safe distance range of the pipeline;

[0024] Step 2: Set up some top anchor support along the length direction on the upper part of the steel sheet piles on both sides, then excavate foundation pits on the outside of the steel sheet piles on both sides, and pour side walls on the outside of the steel sheet piles on both sides and cover plate;

[0025] Step 3: Backfill the foundation pit after the strength of the cover plate and the side walls on both sides reaches 100%. After the foundation pit is backfilled, pull out the steel sheet pile, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com