Method and system for detecting engine knock during transient conditions

An engine and knocking technology, applied in engine components, combustion engines, engine ignition, etc., can solve problems such as unreliable and difficult to accurately assess the presence or absence of engine knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

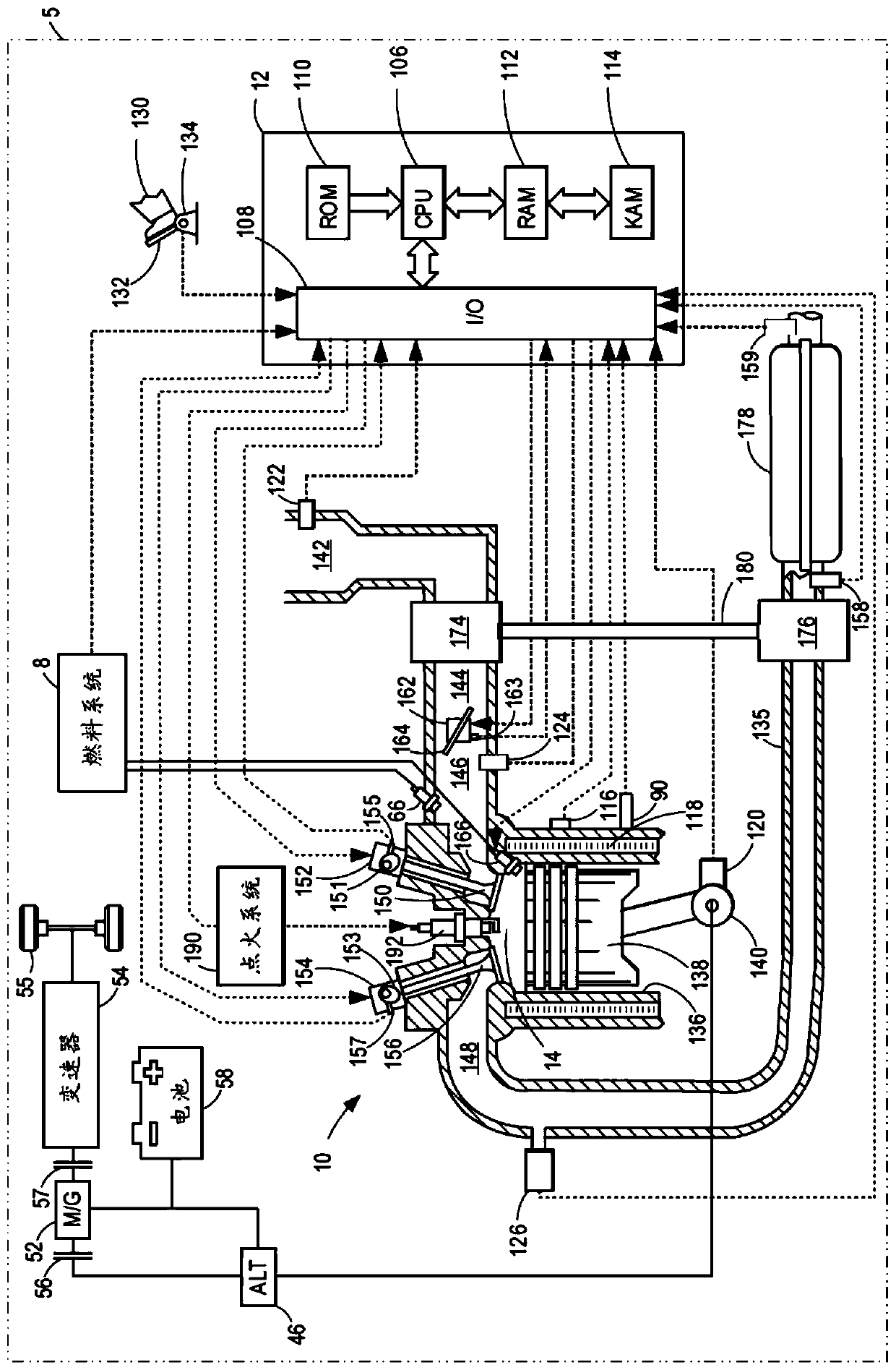

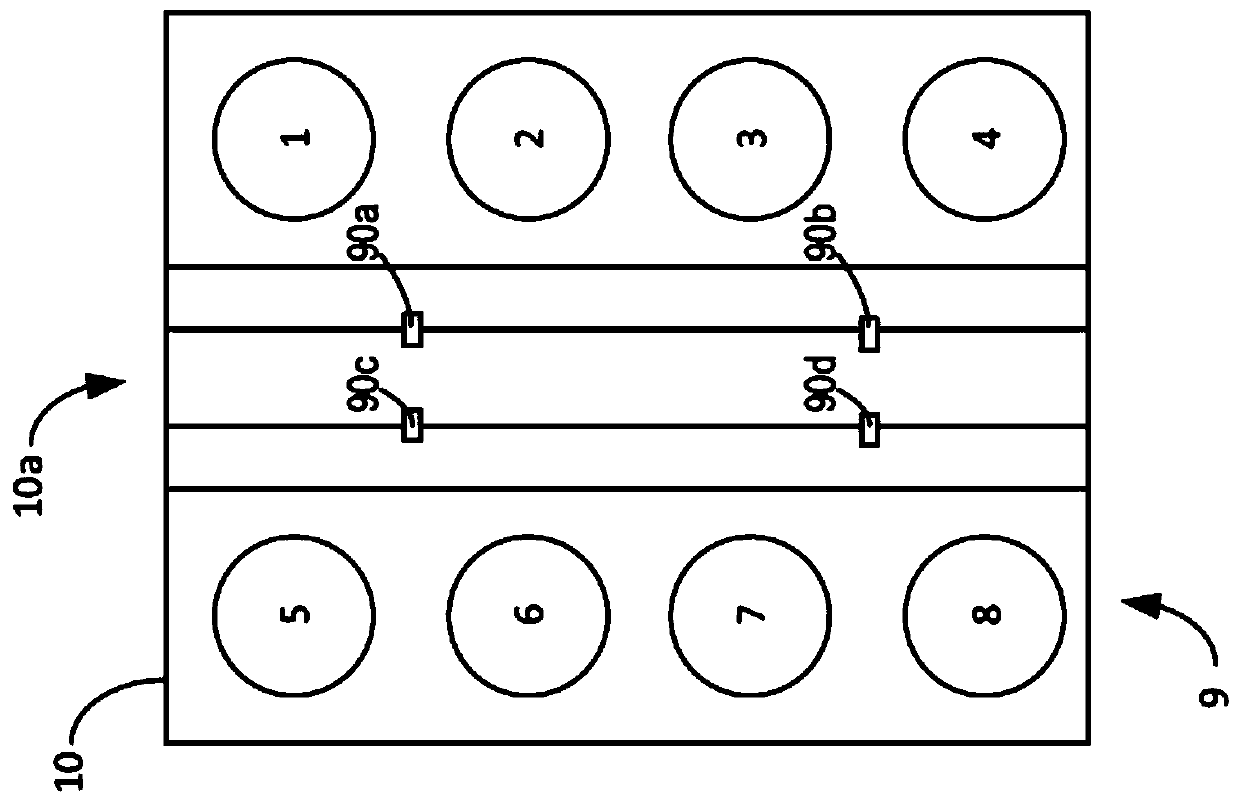

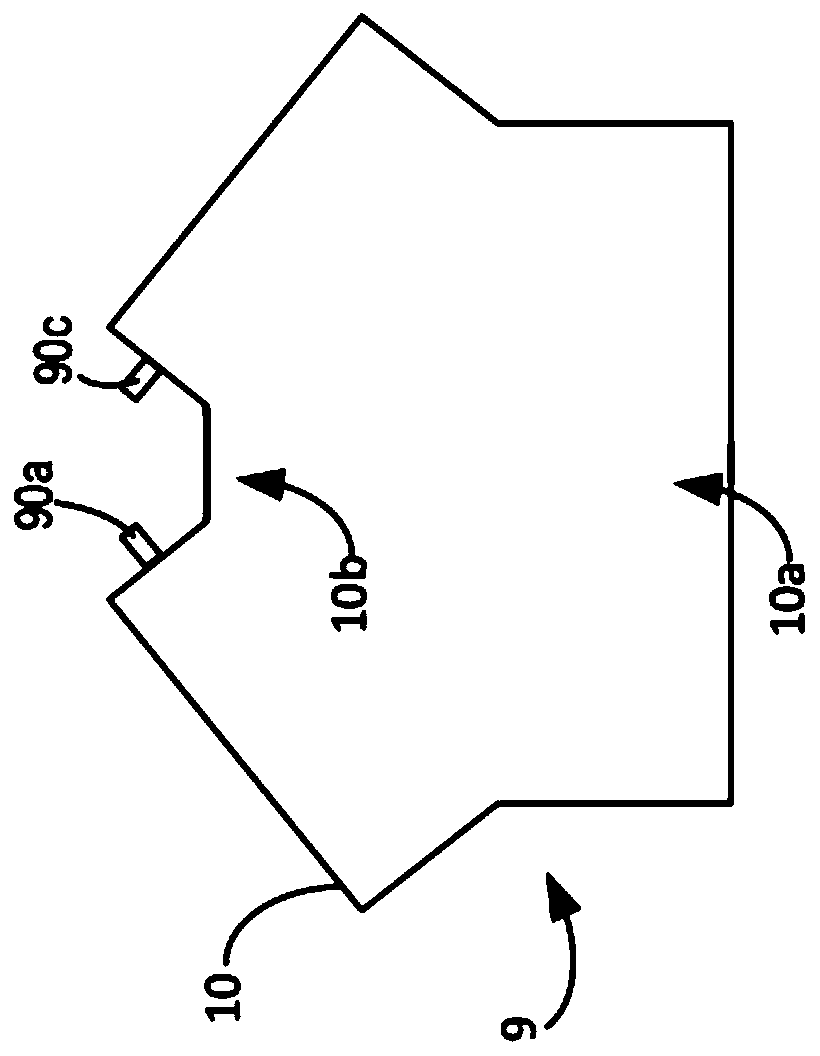

[0015] The following description relates to systems and methods for operating an engine including a knock control system. The engine can be Figure 1A to Figure 1C type shown in . can be based on figure 2 way to operate the engine. The method may use both steady state and transient engine knock background noise levels to determine the presence or absence of engine knock. image 3 An engine operating sequence including an engine knock window is shown. Figure 4 A block diagram showing how the overall engine knock background noise level may be determined. Figure 5 shown for the figure 2 A method for detecting engine knock for an engine operating sequence.

[0016] Turning now to the attached drawings, Figure 1A An example of a cylinder 14 of an internal combustion engine 10 that may be included in a vehicle 5 is depicted. Engine 10 may be controlled at least partially by a control system including controller 12 and by input from a human vehicle operator 130 via an inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com