Method and system for providing engine knock detection dynamic gains

An engine and knocking technology, applied in the direction of electric engine control automatic control, engine components, combustion engines, etc., can solve the problems of inability to detect engine knocking, engine fuel efficiency loss, engine knocking, etc., to improve engine knocking Detect, improve fuel consumption, improve the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

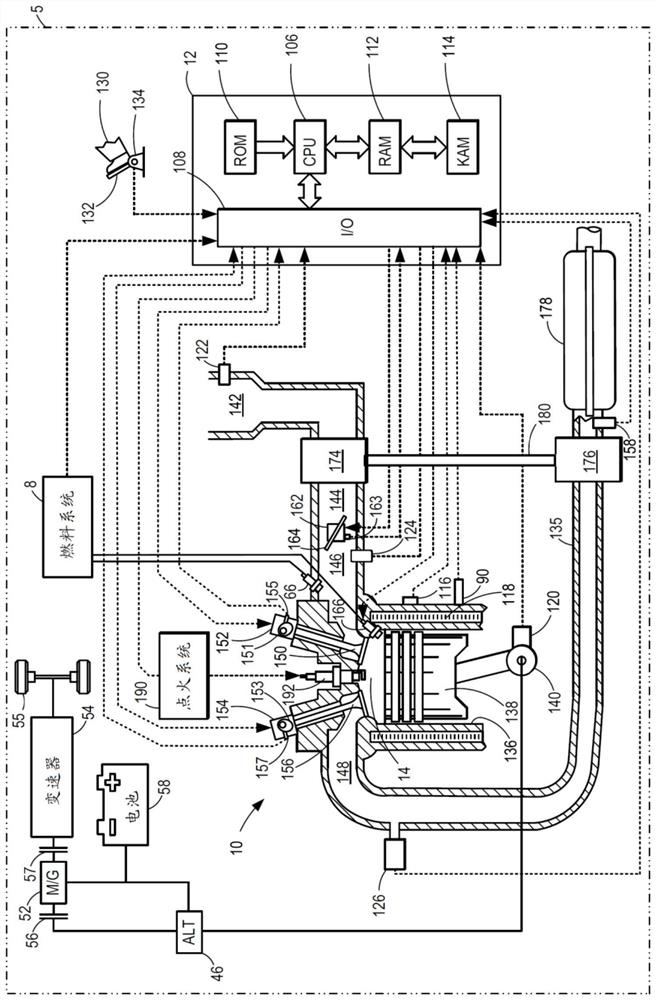

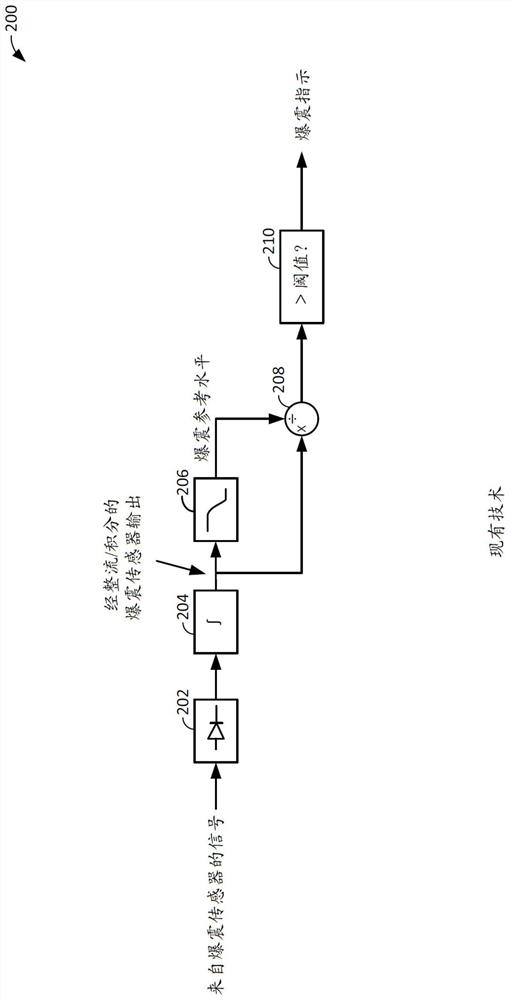

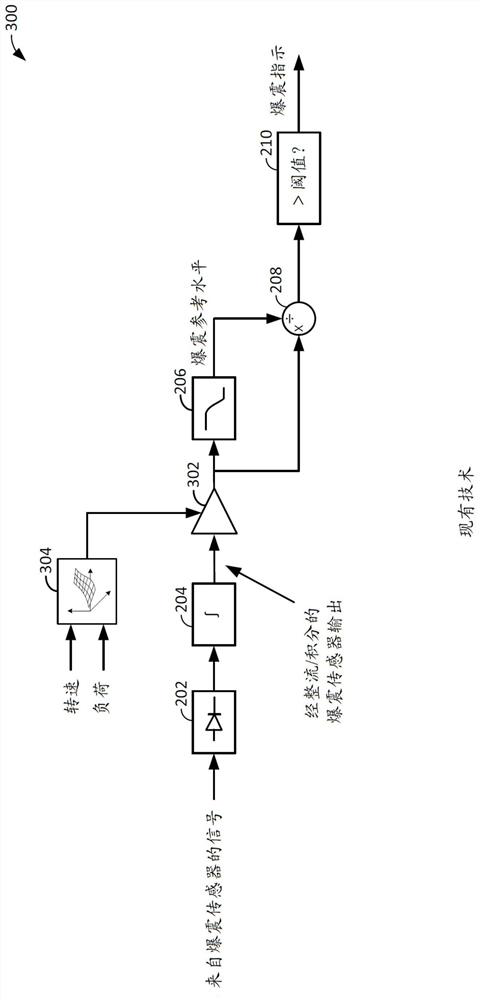

[0013] The following description relates to systems and methods include an engine knock control system for operating. The engine may also include one or more sources of noise, the noise source may result in vibration of the engine, the engine so as to change the reference background or noise level. The engine may be figure 1 Of the type shown in FIG. figure 2 and image 3 It is shown in each portion of the engine knock control system of the prior art. Figure 4 to 6 It is shown in each portion of the engine knock control system according to the present description. Figure 7 Shows a method for operating the engine knock control system.

[0014] Turning now to the drawings, figure 1 Depicts an exemplary internal combustion engine 10 of the cylinder 14, the internal combustion engine 10 may be included in the vehicle 5. The engine 10 may be a variable displacement engine (VDE) as further described herein. Engine 10 may be at least partially comprises a control system 130 by the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com