Pipeline fixing device for road construction

A technology for pipe fixing and road construction, which is applied in the directions of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve the problems of poor applicability, easy displacement, and inability to adjust the pipe fixing device, and achieves easy adjustment and application scope. Wide and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

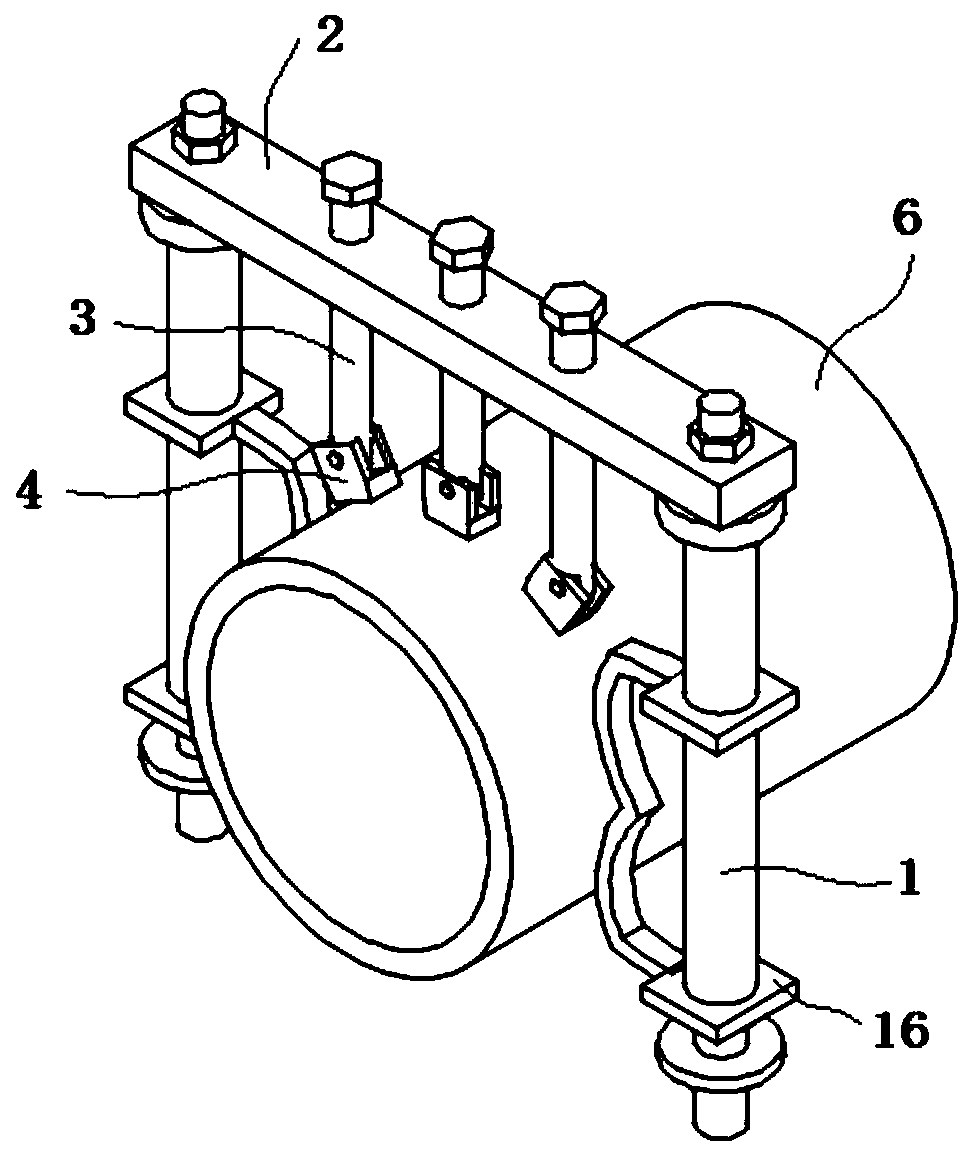

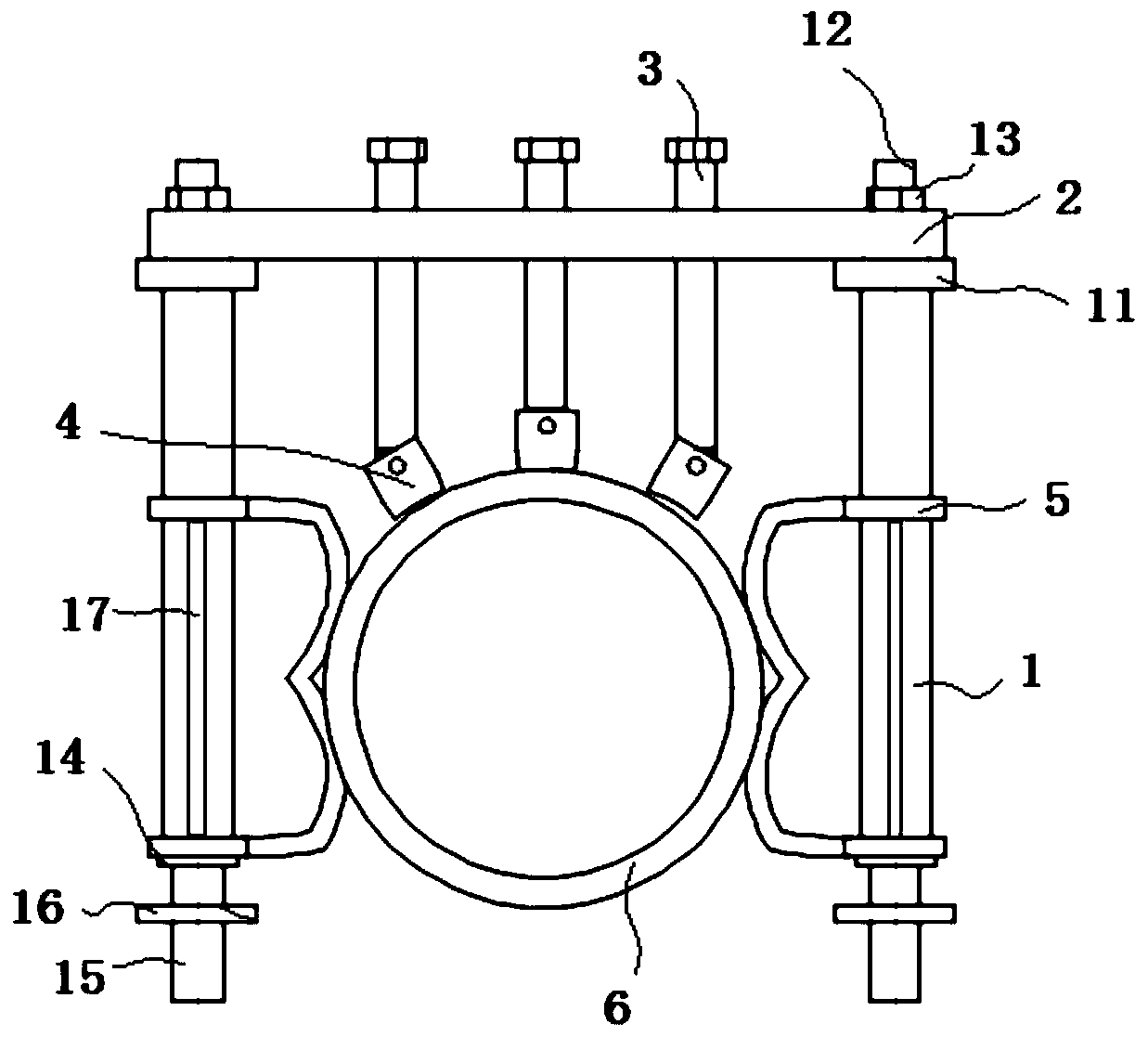

[0032] see Figure 1-5 As shown, a pipeline fixing device for road construction comprises two fixed piles 1 arranged in parallel, and a beam 2 is installed at the ends of the two fixed piles 1; The end is hinged with a block 4.

[0033] Preferably, the block 4 includes a base 41, the bottom side of the U-shaped base 41 is connected to an arc-shaped plate 44 through several buffer blocks 43, and the inner surface of the arc-shaped plate 44 is provided with a contact layer 45; the number of blocks 4 is 3 indivual.

[0034] Preferably, the base 41 is a U-shaped base, and the U-shaped base is provided with a hinge shaft 42 rotatably connected with the fixed screw rod 3 .

[0035] Preferably, the end of the fixed screw 3 is provided with a groove 21 and a shock absorbing spring 22 is fixed at the bottom of the groove 21, and the end of the shock absorbing spring 22 is fixed with a fixed substrate 23 that moves up and down along the groove 21; the fixed substrate 23 is connected ...

Embodiment 2

[0051] see Figure 1-3 Shown in and 6, a pipeline fixing device for road construction comprises two fixed piles 1 arranged in parallel, and a beam 2 is installed at the ends of the two fixed piles 1; The bottom end is hinged with clamping block 4.

[0052] Preferably, the block 4 includes a base 41, the bottom side of the U-shaped base 41 is connected to an arc-shaped plate 44 through several buffer blocks 43, and the inner surface of the arc-shaped plate 44 is provided with a contact layer 45; the number of blocks 4 is 3 indivual.

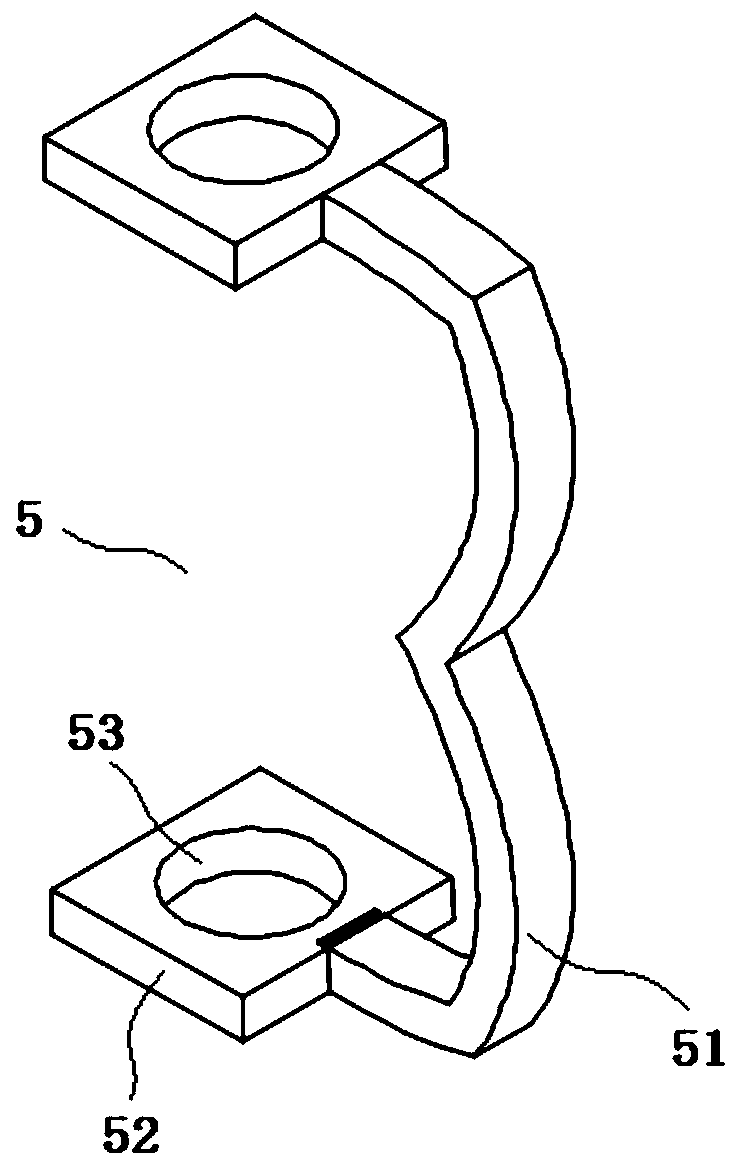

[0053] Preferably, both ends of the base 41 are provided with a hinge seat 46 and a hinge post 47 is provided on the hinge seat 46, and a connecting rod 6 is hinged on the hinge post 47;

[0054] Wherein, the two connecting rods 6 on the two adjacent blocks 4 are rotationally connected by a rotating shaft 61;

[0055] Wherein, between the base 41 and the fixed screw rod 3, there is a connecting rod with a cross-section of "I" shape; the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com