Rifle shooting training fixer

A technology for fixers and automatic rifles, applied in the direction of training fit parts, weapon accessories, offensive equipment, etc., can solve problems such as poor stabilization effect and inconsistent shooter distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

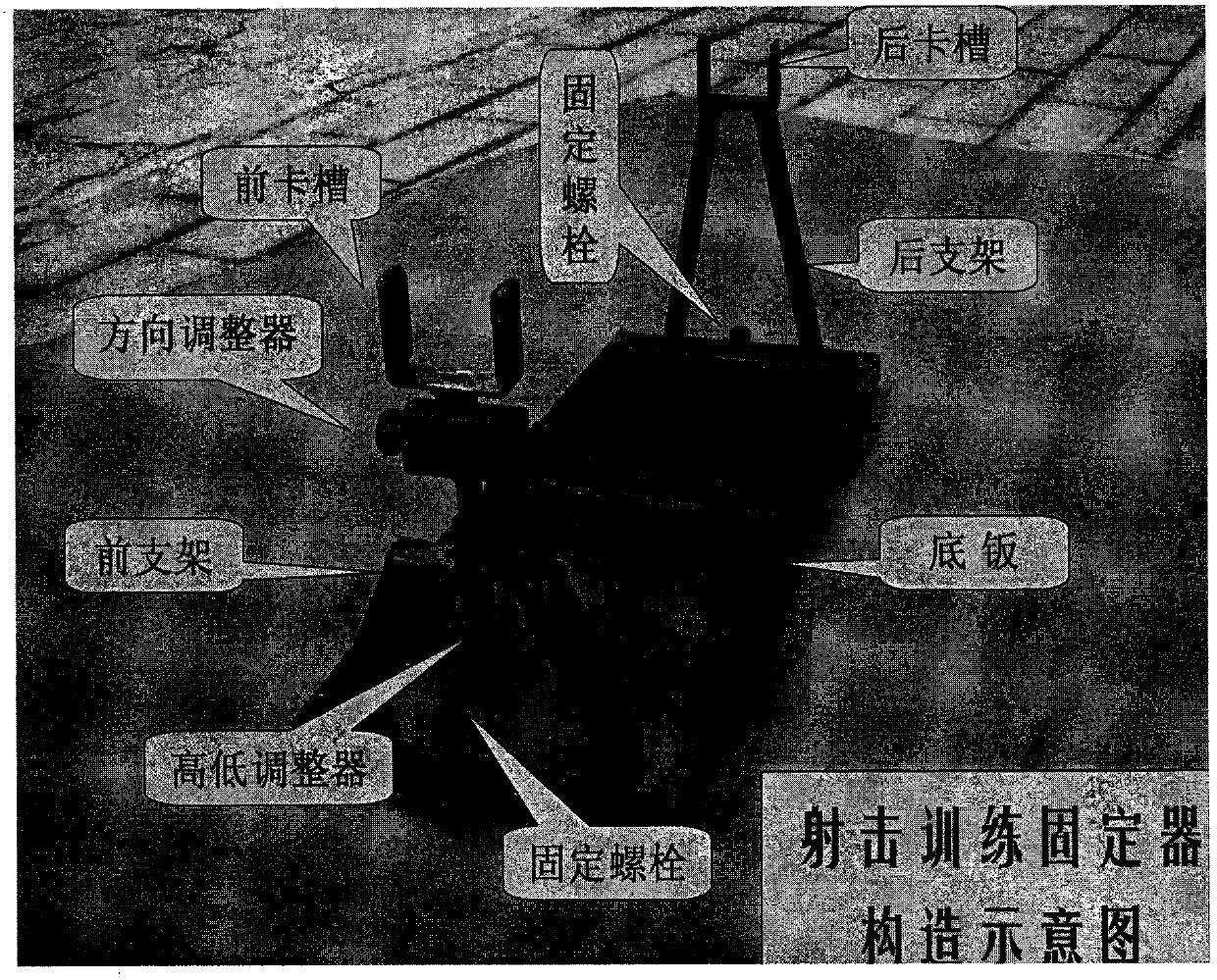

[0032] figure 1 The implementation flow of the embodiment of the present invention is shown.

[0033] Rifle shooting training fixer, the equipment includes the following parts:

[0034] Fixing bolts

[0035] Front card slot

[0036] Rear card slot

[0037] front bracket

[0038] rear bracket

[0039] direction adjuster

[0040] height adjuster

[0041] Bottom plate

[0042] The overall structure adopts a folding steel bracket structure and a convenient height and direction adjustment device. The total weight is 4 kg, the length is 25 cm, the width is 21 cm, and the thickness is only 2.2 cm. It is in the shape of a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com