A high temperature resistant radial displacement sensor device

A sensor device and radial displacement technology, applied in the field of sensor detection, can solve the problems of unstable measurement circuit, inability to measure for a long time, long-term stable measurement, etc., and achieve the effects of easy adjustment, good conductivity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below with reference to the specific embodiments of the present invention and the corresponding drawings.

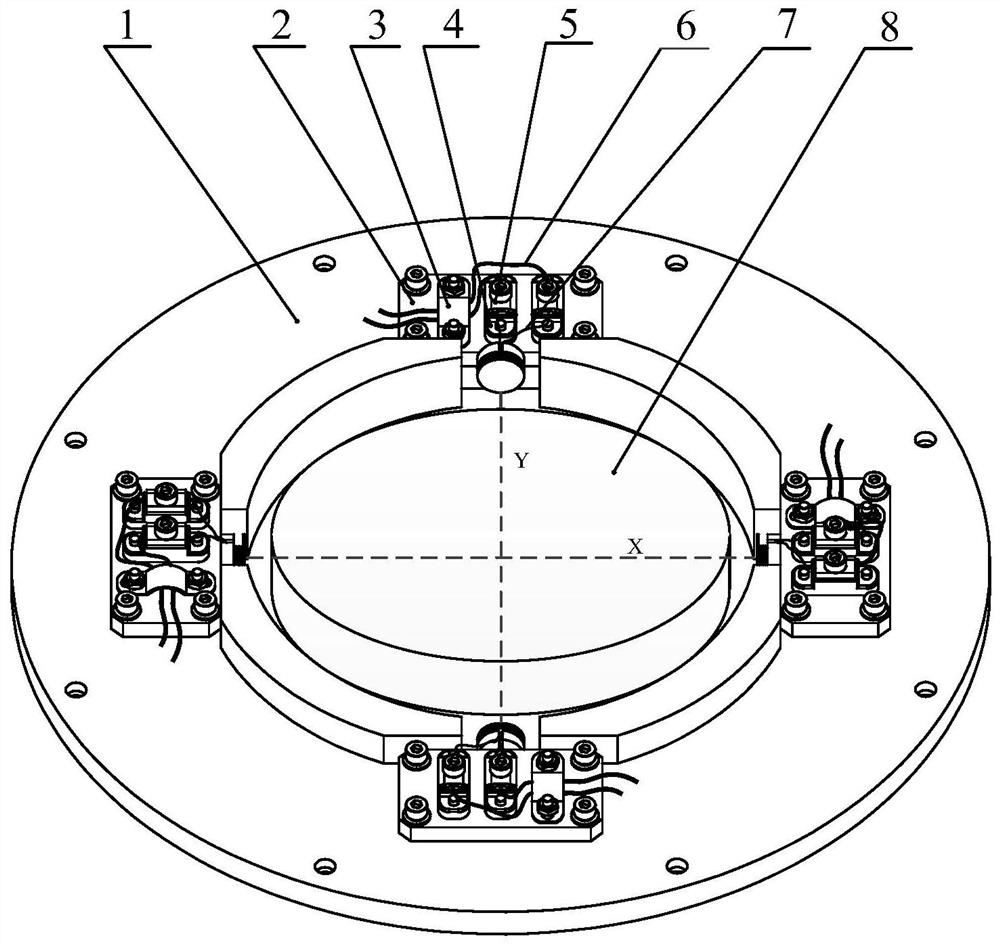

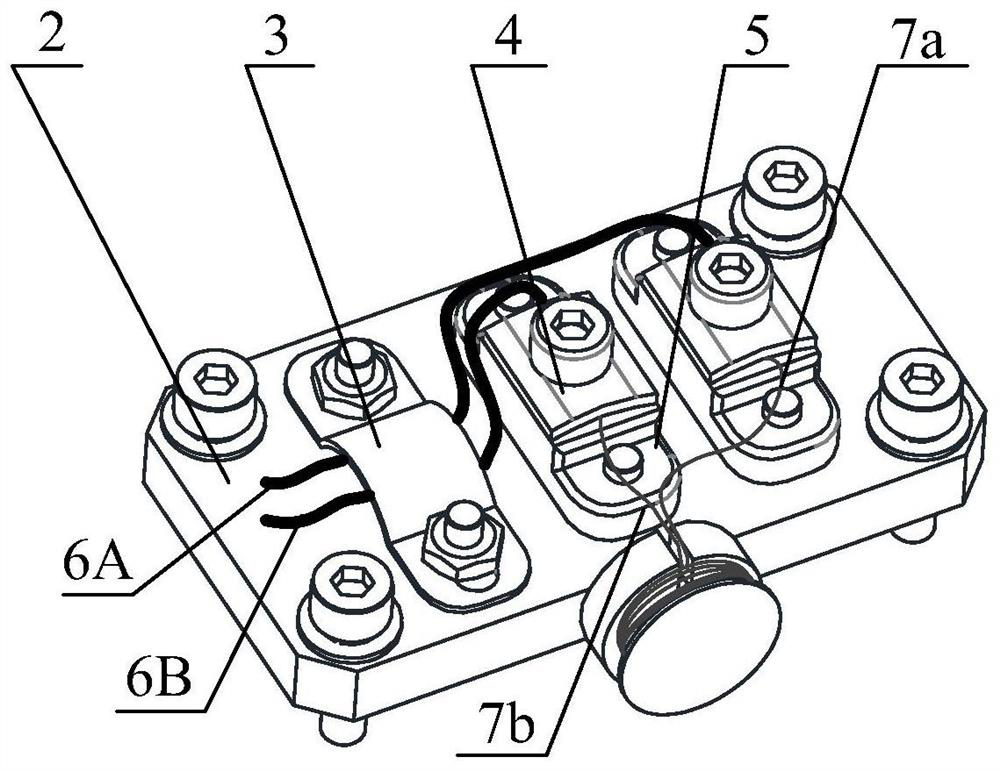

[0026] like figure 1 As shown, the present invention is a non-contact, leadless, high-temperature radial displacement sensor device for magnetic suspension bearings, which mainly includes: a sensor support 1, a sensor probe assembly, and the sensor probe assembly includes a sensor probe 2, a fixing wire piece 3. Clamp 4, terminal block 5, high temperature resistant lead wire 6, induction coil 7.

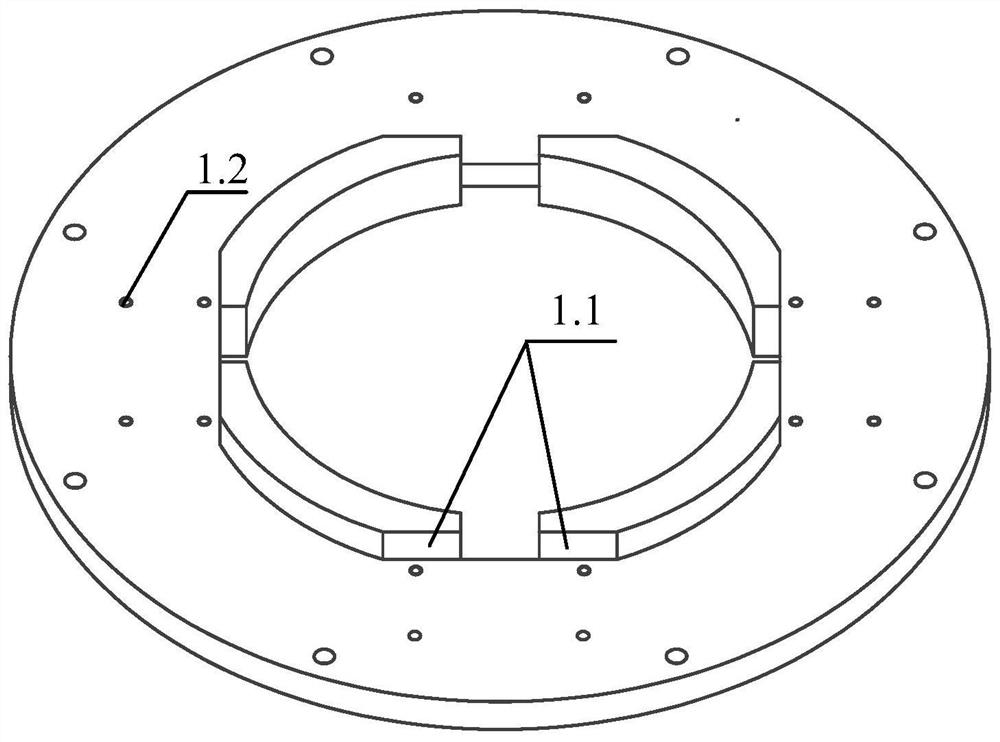

[0027] like figure 2 As shown, the vertical plane 1.1 on the sensor support 1 provides an installation reference surface for the detection distance (less than 1mm) between the sensor probe 2 and the detection surface of the magnetic suspension rotor 8, and the four positioning con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com