High-precision optical extensometer based on color camera, and measurement method

A technology of optical extensometer and color camera, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of limited application and high cost, eliminate false displacement and false strain, improve measurement accuracy, and improve strain measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

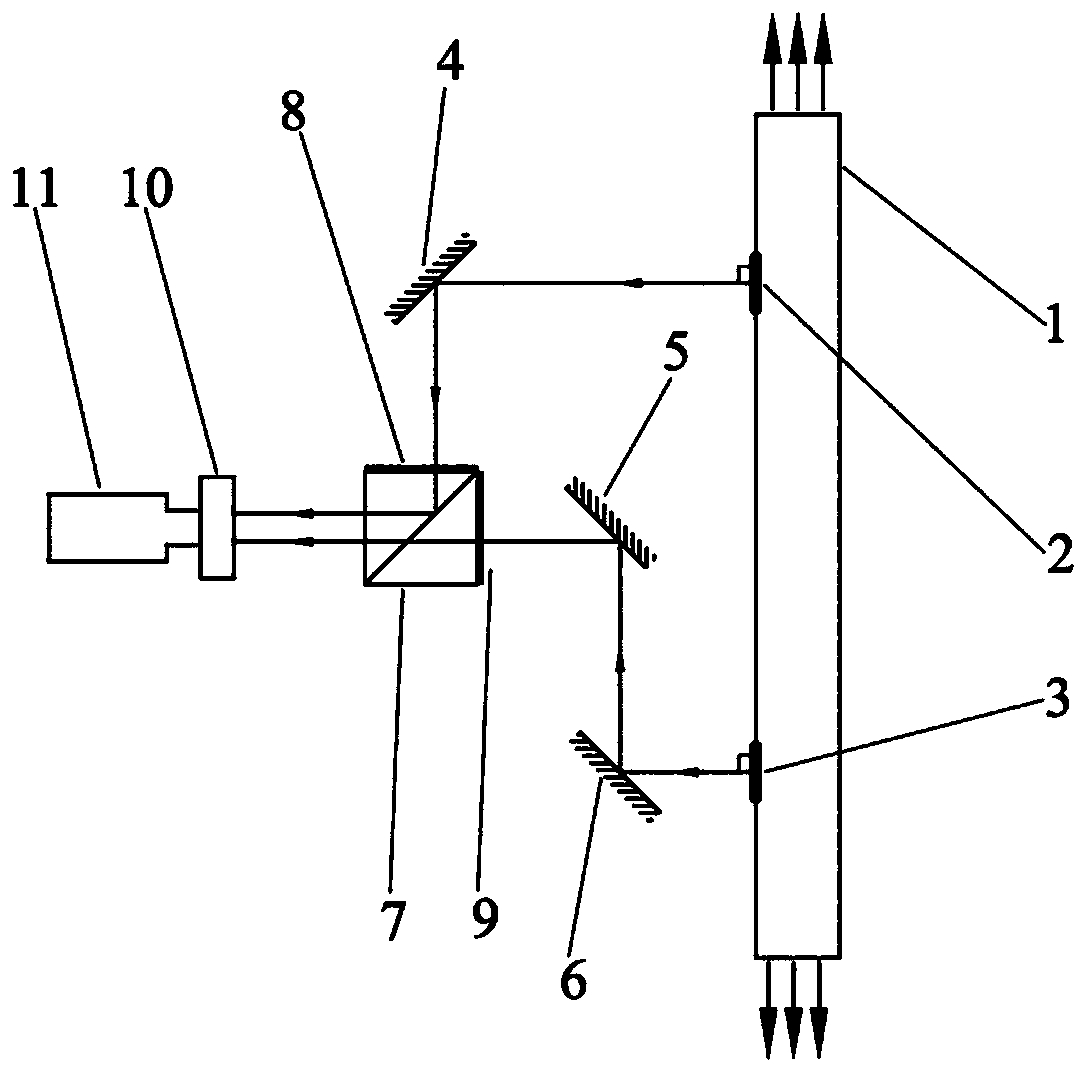

[0032] Such as figure 1 As shown, a high-precision optical extensometer based on a color camera disclosed in the embodiment of the present invention includes a color digital camera 11, a long focal length lens 10, a dichroic prism 7, a blue color filter 8, a red A color filter 9, a first reflector 4, a second reflector 5, a third reflector 6 and a data processing device.

[0033] The blue color filter 8 and the red color filter 9 are respectively covered on two adjacent surfaces of the dichroic prism 7. Specifically, the dichroic prism 7 includes four surfaces (two are parallel to the optical axis of the long focal length lens 10). surface, two surfaces perpendicular to the optical axis of the telephoto lens 10), the red color filter 9 is located on the farther surface of the telephoto lens 10 among the two surfaces perpendicular to the optical ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com