Support generation method of 3D printed denture bracket

A 3D printing and denture technology, applied in the field of 3D printing, can solve the problems of complex denture bracket model, lack of horizontal pulling force, consumption of metal powder, etc., to reduce material cost, facilitate removal, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

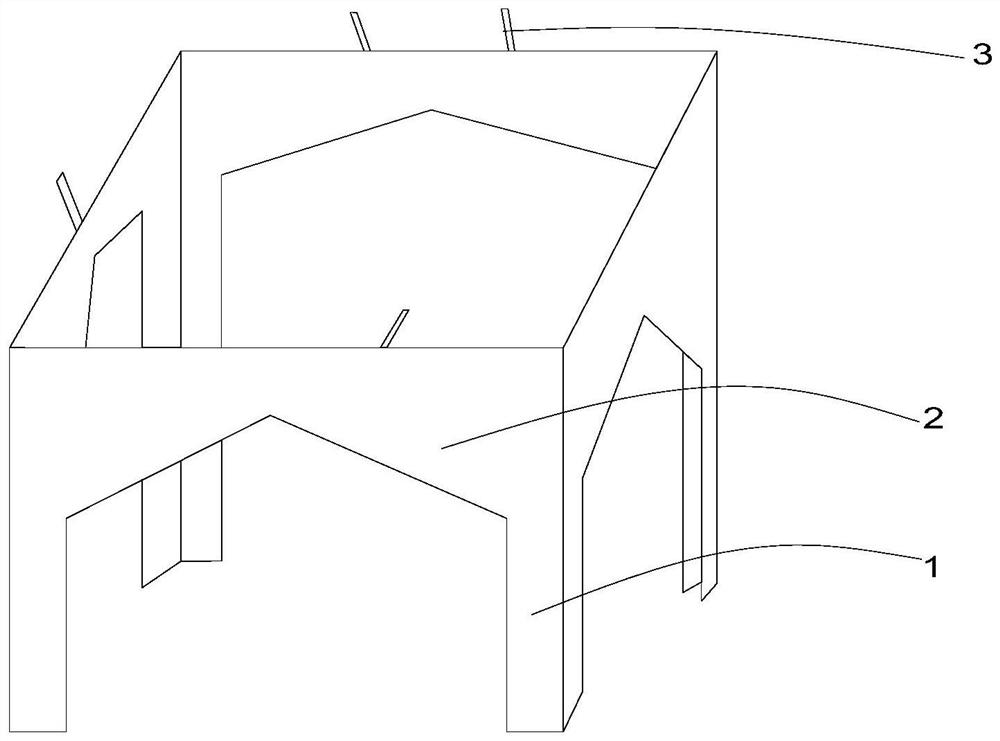

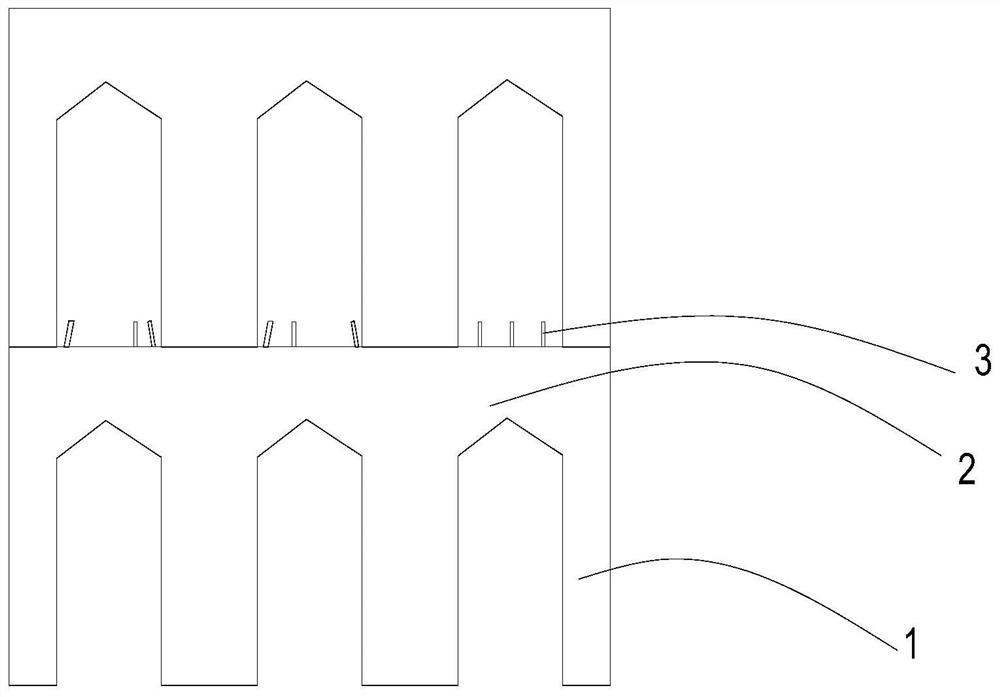

[0051] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

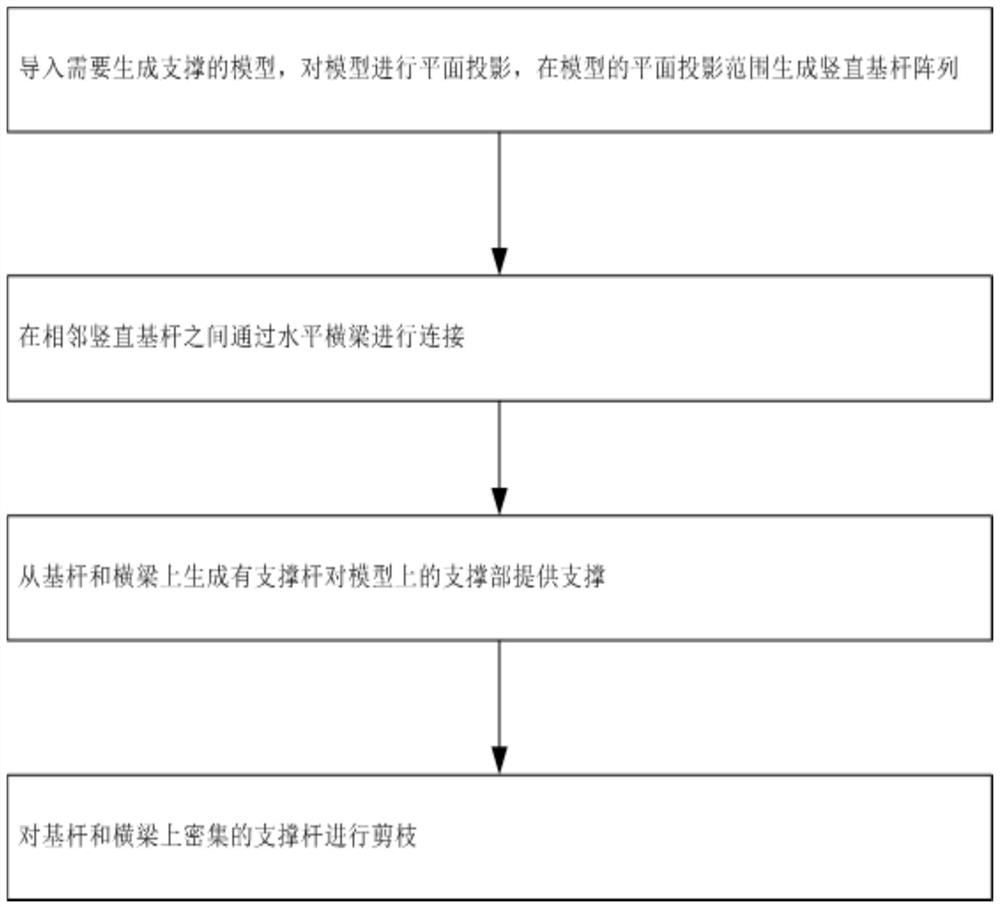

[0052] like figure 1 Shown: a support generation method for a 3D printed denture bracket, including the following steps:

[0053] S1: Import the model that needs to generate supports, project the model on the xy plane, and generate a base rod array within the plane projection range of the model, and the base rods are set vertically;

[0054] Wherein, in this embodiment, the S1 includes the following steps:

[0055] S11: Import the model that needs to generate support, read the triangular patch of the model, and generate the minimum bounding box of the model;

[0056] S12: Project the bounding box on the xy plane to obtain the model projection r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com