Laser cloth cutting machine

A cloth cutting machine and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of affecting cloth transmission, affecting the accuracy of cutting cloth, and large suction area, so as to improve transmission efficiency and precision, The effect of avoiding precision reduction and ensuring cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

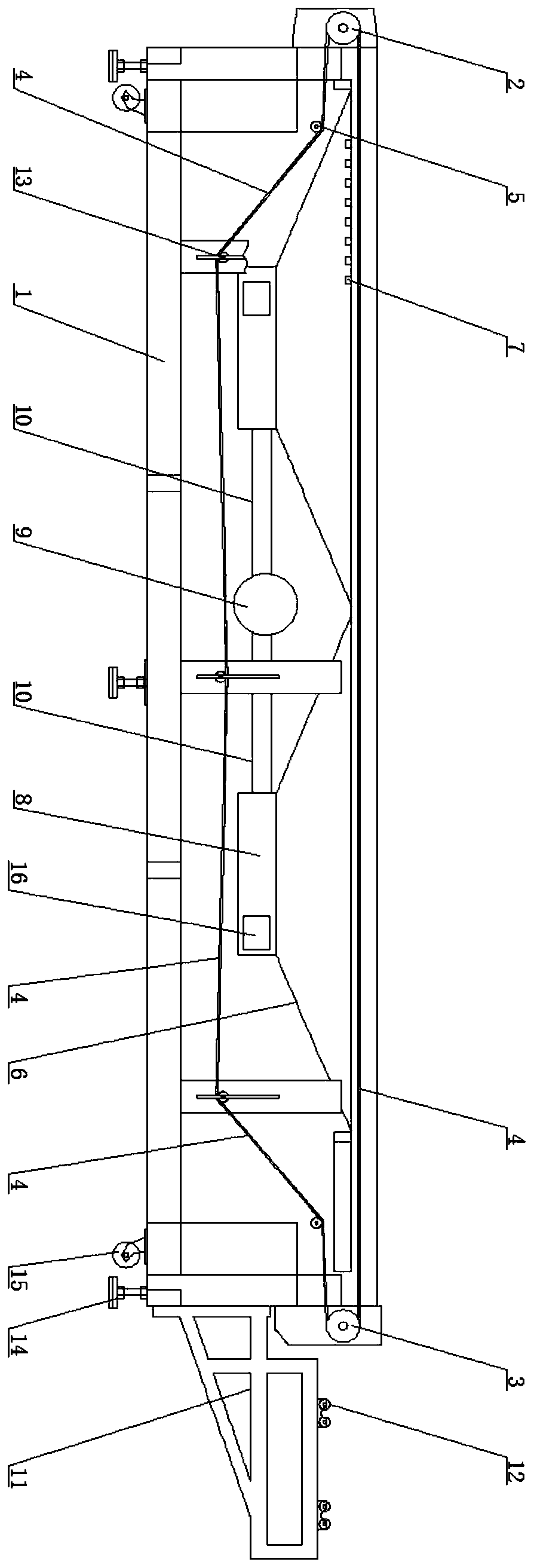

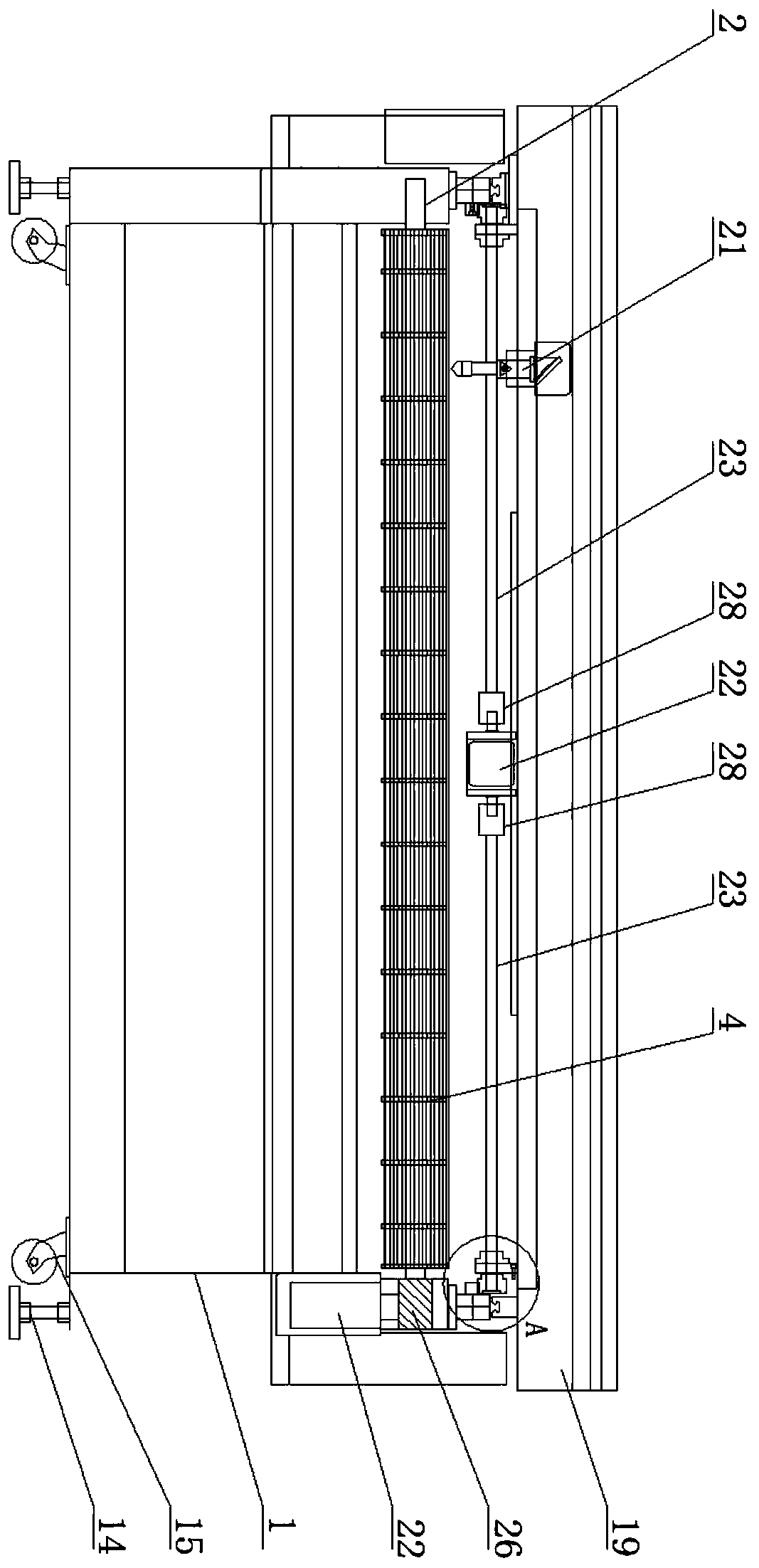

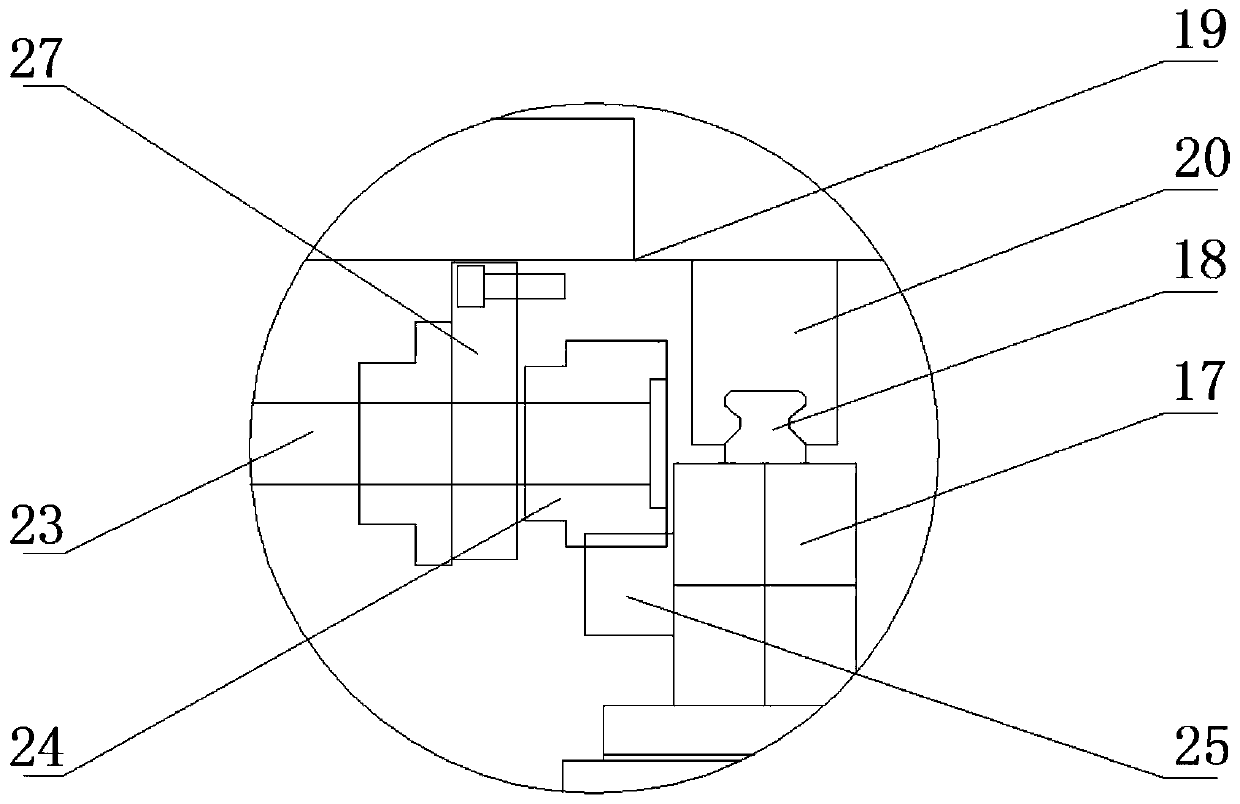

[0019] Such as figure 1 As shown, a laser cloth cutting machine includes a frame 1; a driving shaft 2 is provided on the front side of the upper end of the frame 1, and a corresponding driven shaft 3 is provided on the rear side of the upper end, and the driving shaft 2 and the driven shaft 3 are arranged between There is a transmission mesh belt 4, the upper layer mesh belt of the transmission mesh belt 4 is a plane structure used to drive the cloth, and the lower layer mesh belt of the transmission mesh belt 4 is guided by the guide shaft 5 provided on the frame 1 and then from the fra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap