LED touch screen display diaphragm mounting structure for curved surface

An installation structure and display film technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve touch failure, unable to remove bubbles on the diaphragm and curved screen body, touch screen and curved screen No contact and other problems, to achieve the effect of easy operation and easy fixation of the curved screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

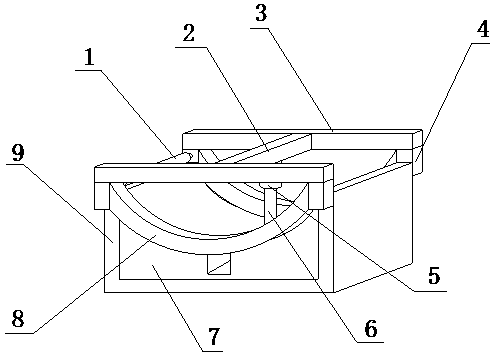

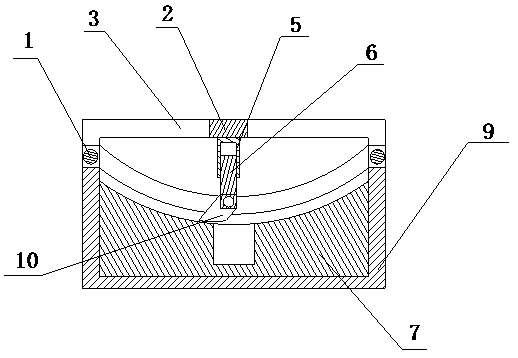

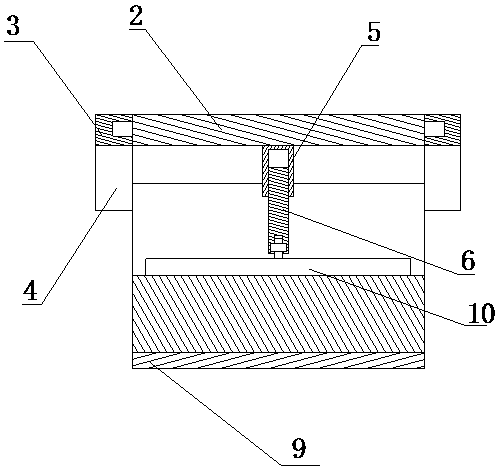

[0018] see Figure 1-Figure 3 , the present invention provides a technical solution: an LED touch screen display diaphragm installation structure for curved surfaces, including a flexible roller 1, a moving vertical bar 2, a fixed horizontal bar 3, a bump 4, a sleeve 5, and a connecting rod 6 , rock wool board 7, elliptical rod 8, U-shaped board 9 and flexible scraper 10, rock wool board 7 is fixed on the inner upper end surface of U-shaped board 9, bump 4 is installed on the front end face of U-shaped board 9, and the cross bar is fixed 3 is fixed on the upper end surface of the bump 4, the moving vertical bar 2 is assembled between the fixed cross bars 3, the sleeve 5 is fixed on the lower end surface of the moving vertical bar 2, the connecting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap