Vehicle sandwich member and method for manufacturing vehicle sandwich member

A technology for sandwich components and vehicles, applied in vehicle components, chemical instruments and methods, applications, etc., can solve problems such as troublesome, expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

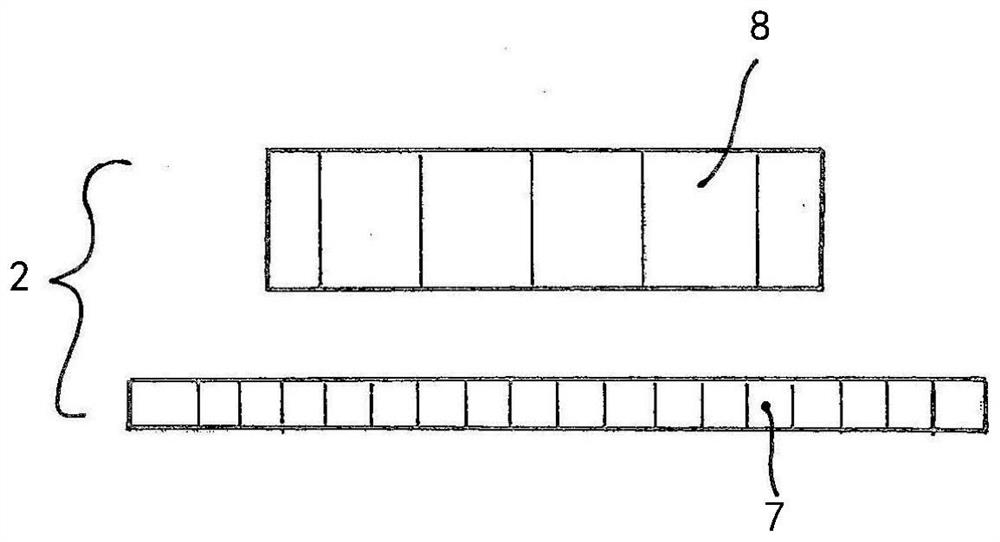

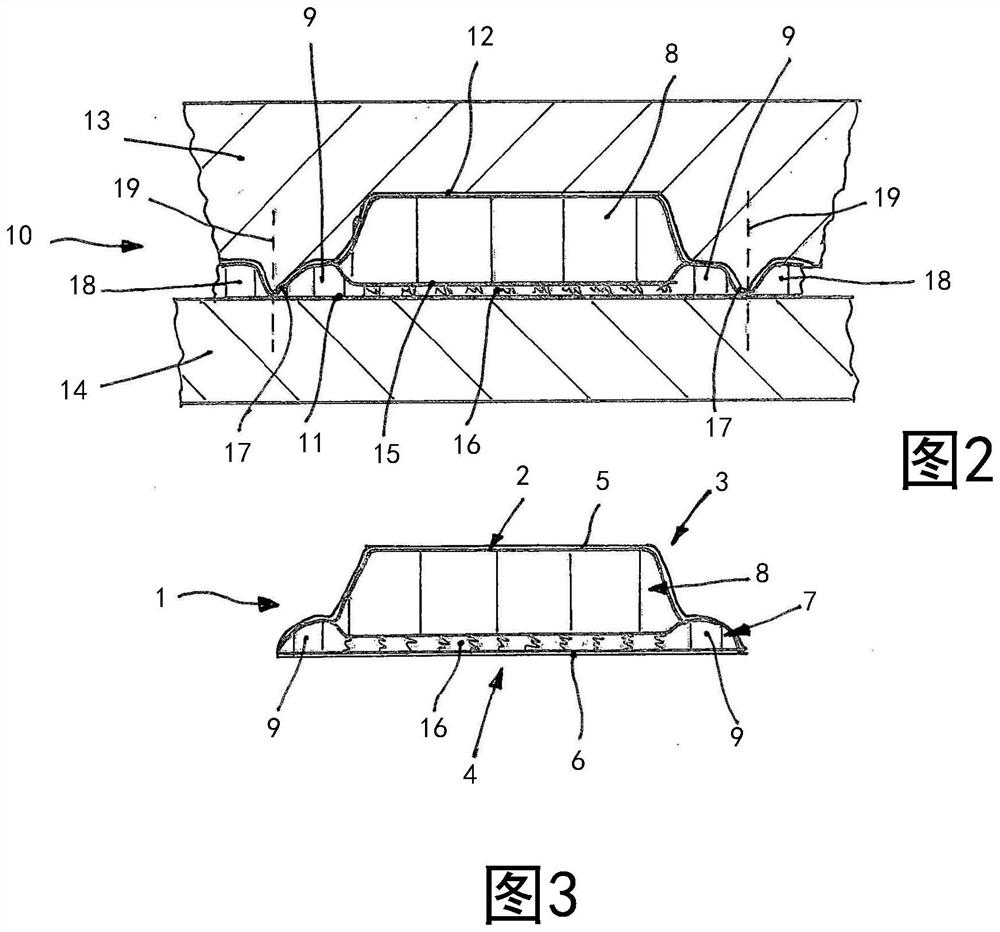

[0023] Sandwich member 1 of the vehicle (see image 3 ), for example a part of a roof module or a cover of an openable roof such as a sliding roof or a sliding lift roof etc. has a layer structure with a central honeycomb structure 2 as a core layer and applied to a sandwich component Covering layer 5 or 6 on both sides or on the outer side 3 and inner side 4 of the sandwich component 1 .

[0024] The honeycomb structure 2 comprises a first honeycomb layer 7 and a second honeycomb layer 8 . exist figure 1 The first honeycomb layer 7 shown as the lower part and forms the inner lower honeycomb layer 7 in the sandwich member 1 than in figure 1 The second honeycomb layer 8 , which is shown as the upper part and forms the outer upper honeycomb layer 8 in the sandwich component 1 , has a larger surface area. The first lower honeycomb layer 7 has a particularly uniform thickness which is smaller than the thickness of the second upper honeycomb layer 8 . The first lower honeycomb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com