Washing machine

A technology for washing machines and storage parts, which is applied in the field of washing machines, and can solve the problems of affecting the liquid tightness of the joints, the inability to discharge detergent liquid or softener liquid stably, and the adhesion of the joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

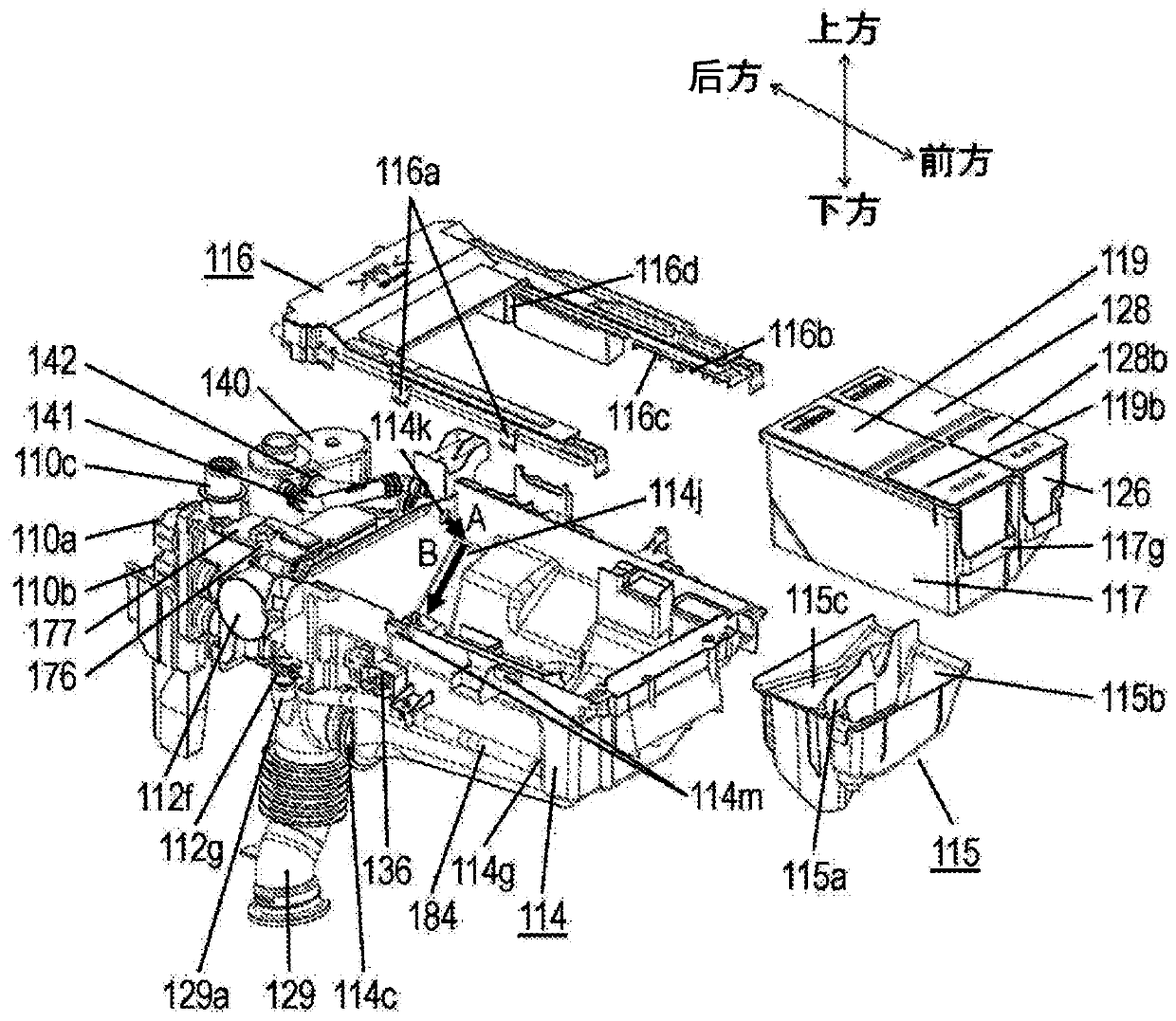

[0058] Below, use Figure 1~Figure 38 The washing machine of this embodiment will be described separately for each item.

[0059] [1-1. Structure]

[0060] [1-1-1. Structure of washing machine]

[0061] First, refer to figure 1 with figure 2 The structure of the washing machine of this embodiment is demonstrated.

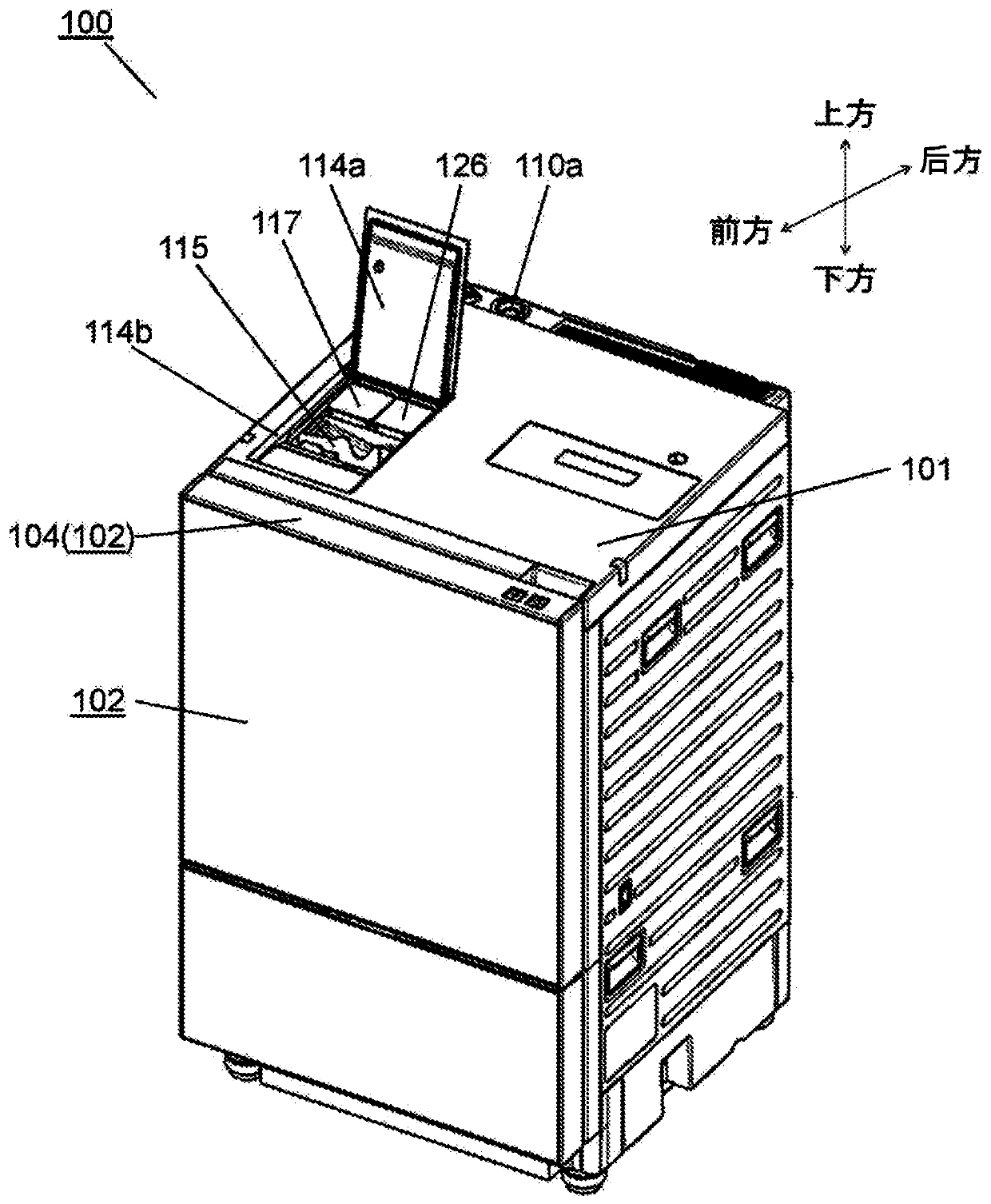

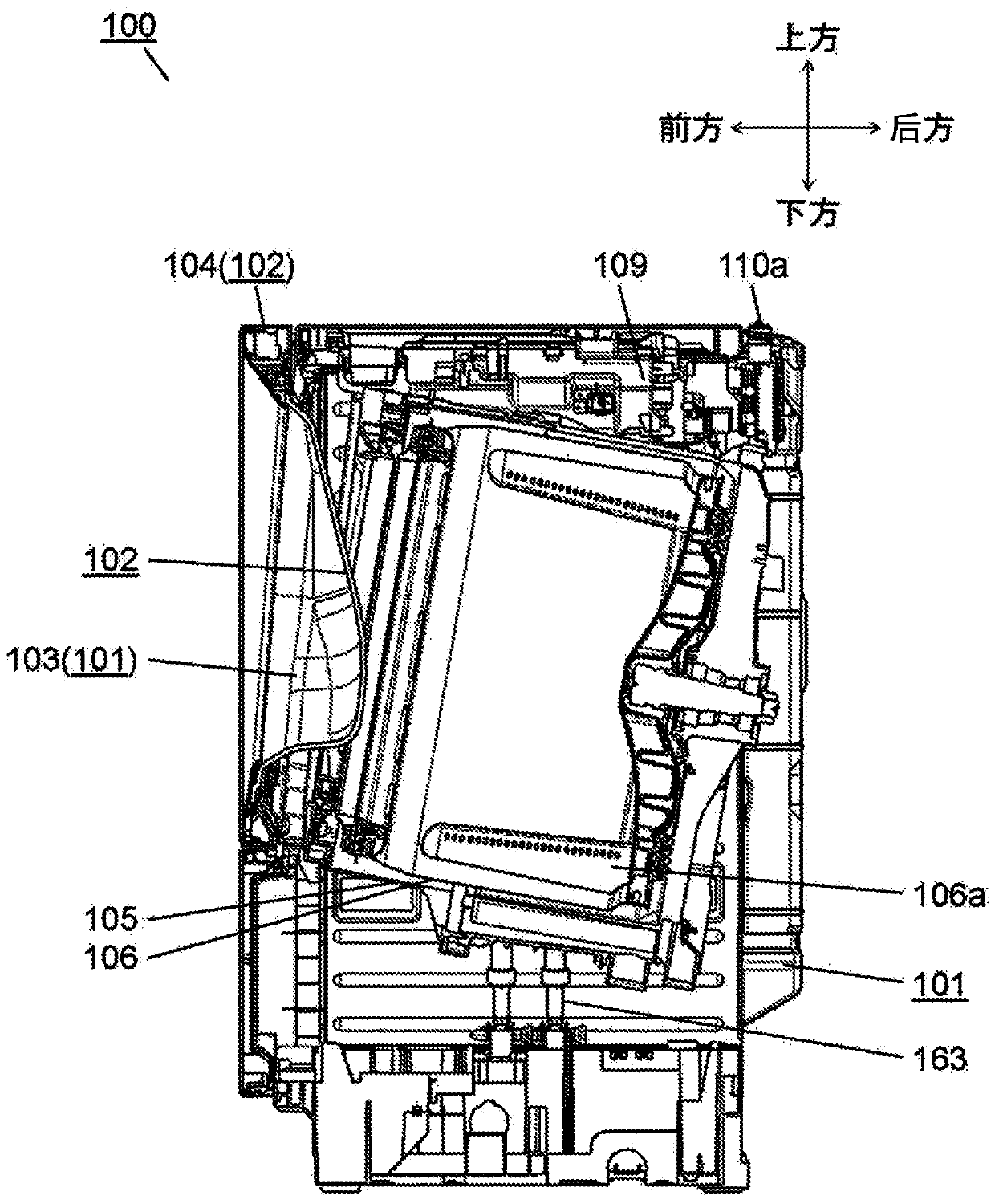

[0062] figure 1 It is an external perspective view of the washing machine of this embodiment. figure 2 It is a figure which shows the longitudinal cross-section of the said washing machine.

[0063] Such as figure 1 with figure 2 As shown, the washing machine of this embodiment includes a casing 101 and a bottomed cylindrical water tank 105 provided inside the casing 101 and the like. The housing 101 constitutes the outline of the washing machine 100. The water tank 105 is elastically vibration-isolated and supported by a plurality of suspension parts (not shown) and a shock absorber 163. A bottomed cylindrical drum 106 constituting a washing tub is rotatably arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com