Plastic cap and manufacturing method thereof

A technology for plastic lids and lids, applied to other household appliances, closures, packaging, etc., can solve the problems that it is impossible to form openings easily, achieve the effects of preventing the reduction of airtightness, excellent productivity, and ensuring liquid tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

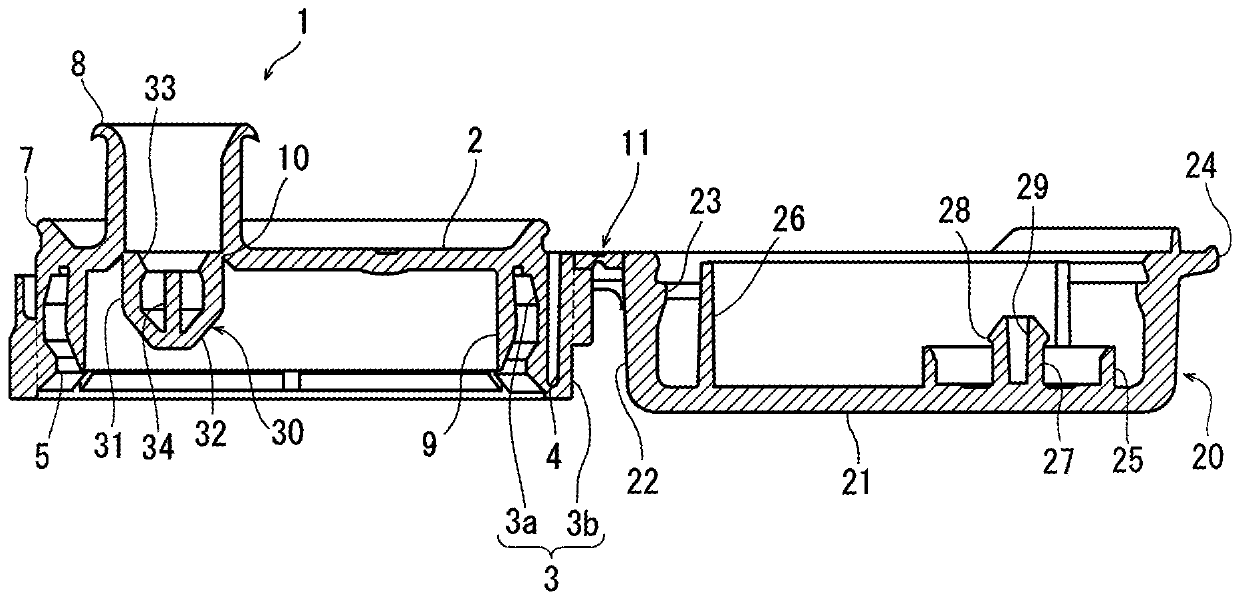

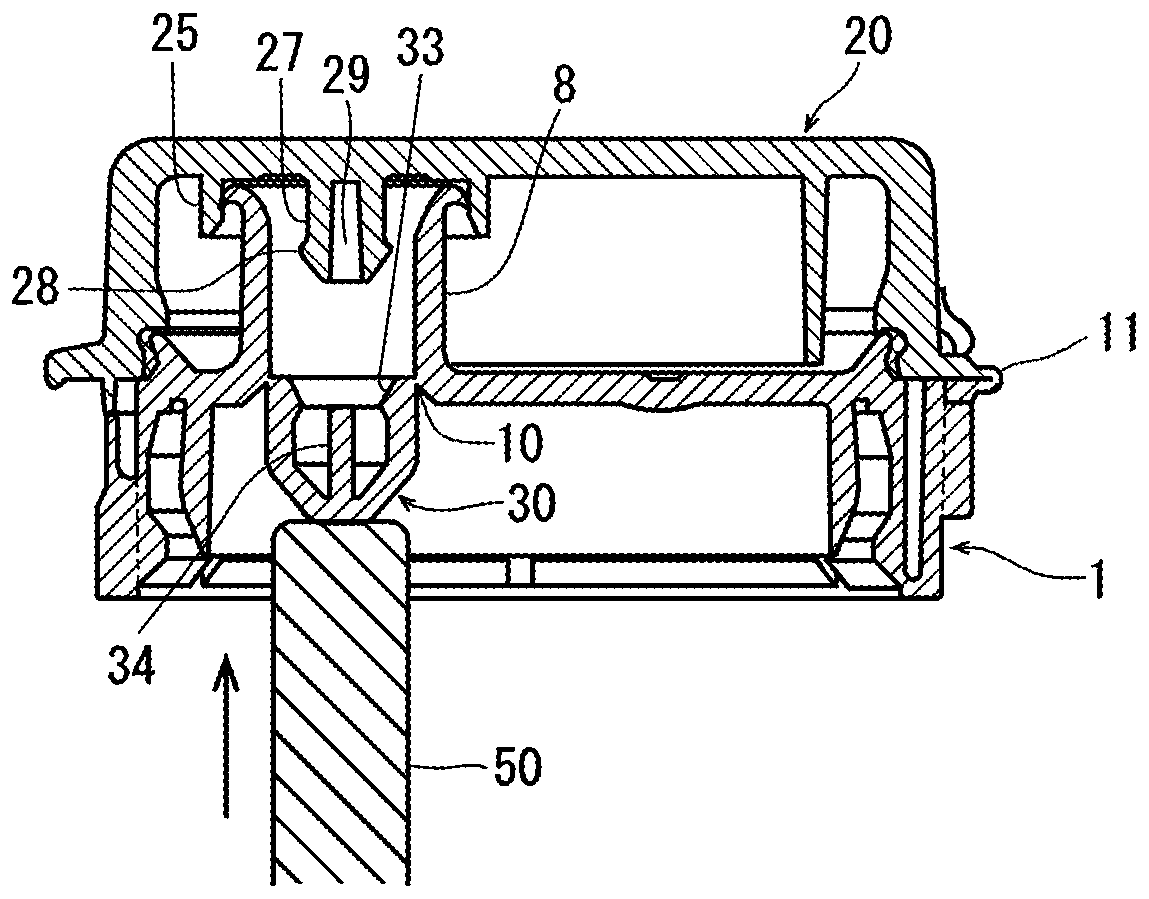

[0044] The plastic cap of the present invention will now be described with reference to the accompanying drawings.

[0045] Figure 1-7One example of the plastic cover of the present invention shown is a hinged cover comprising a cover body 1, a top cover 20 connected to the cover body 1 by a hinge 11, and an inner plug 30 formed to be removable from the cover body 1. Detached and can be integrated with the top cover after detachment from the cover body, the hinged cover is formed by integrally molding these parts.

[0046] A cap body 1 to be assembled and fixed to a container mouth (not shown) includes a top plate portion 2 and a skirt portion 3 depending from the periphery of the top plate portion 2 . The skirt 3 is divided into an inner cylinder wall 3 a and an outer cylinder wall 3 b formed as if surrounding the inner cylinder wall 3 a by a groove 4 extending from above to below. At the lower end of the groove 4 , a slit 12 penetrates through a local area in the circumfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com