Online disassembling and assembling tool for top-mounted ball valve

A technology for disassembly tools and ball valves, which is applied in the field of online disassembly tools for top-loading ball valves, can solve the problems of complex structure, increased manufacturing cost, and asymmetrical force on valve seats, etc., and achieves simple and convenient disassembly operations, low manufacturing costs, and occupying small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

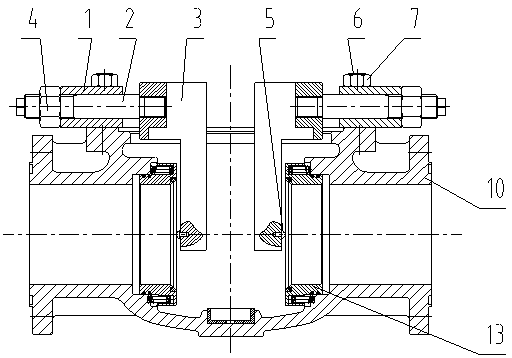

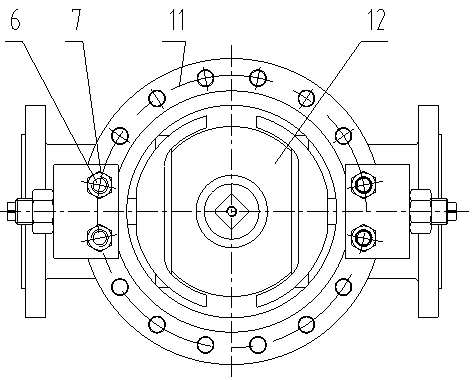

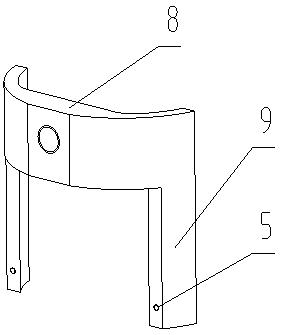

[0016] Such as figure 1 , 2 , 3, the top-loading ball valve online disassembly tool of the present invention is composed of a base 1, an operating arm 3 and a driving mechanism. The driving mechanism is composed of a screw rod 2 and a driving nut 4 . The base 1 is a rectangular parallelepiped metal block, on which there are two mounting holes penetrating up and down. The two mounting holes pass through two adjacent bolts 6 of the flange 11 in the valve body 10 on the side of the valve seat, and are connected with nuts 7. Fix the base on the middle flange. The base is provided with a front and rear through hole, and the screw rod 2 is arranged in the base through hole, and one end thereof is threadedly connected with the semi-circular plate of the operating arm. The other end is provided with a driving nut 4 matched therewith. The upper part of the operating arm is a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com