Online swinging device for canned products

A technology of rocking device and product line, applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problems of uneven shaking, inability to shake well, low efficiency, etc., and achieve low failure rate, stable production quality, and production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

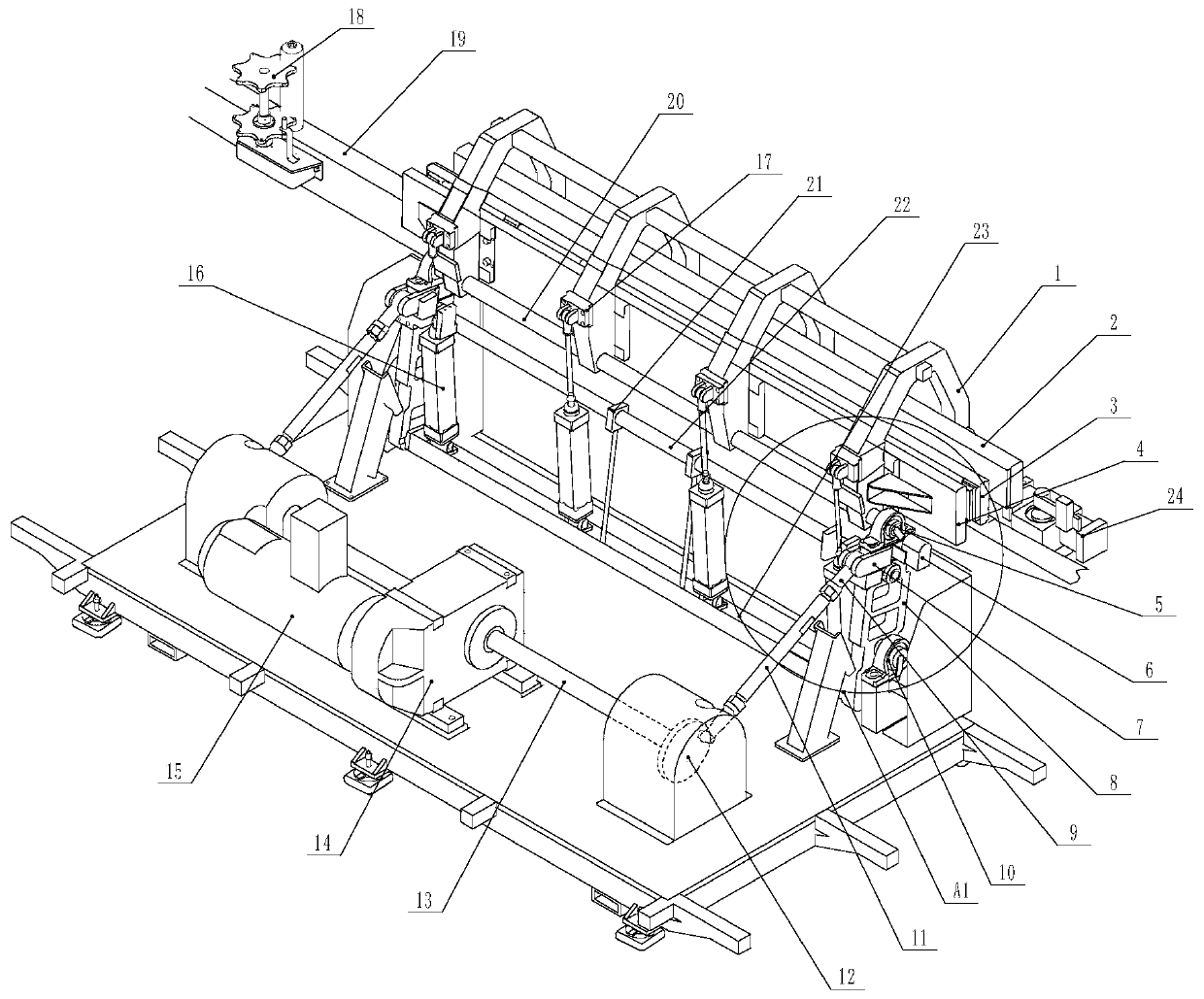

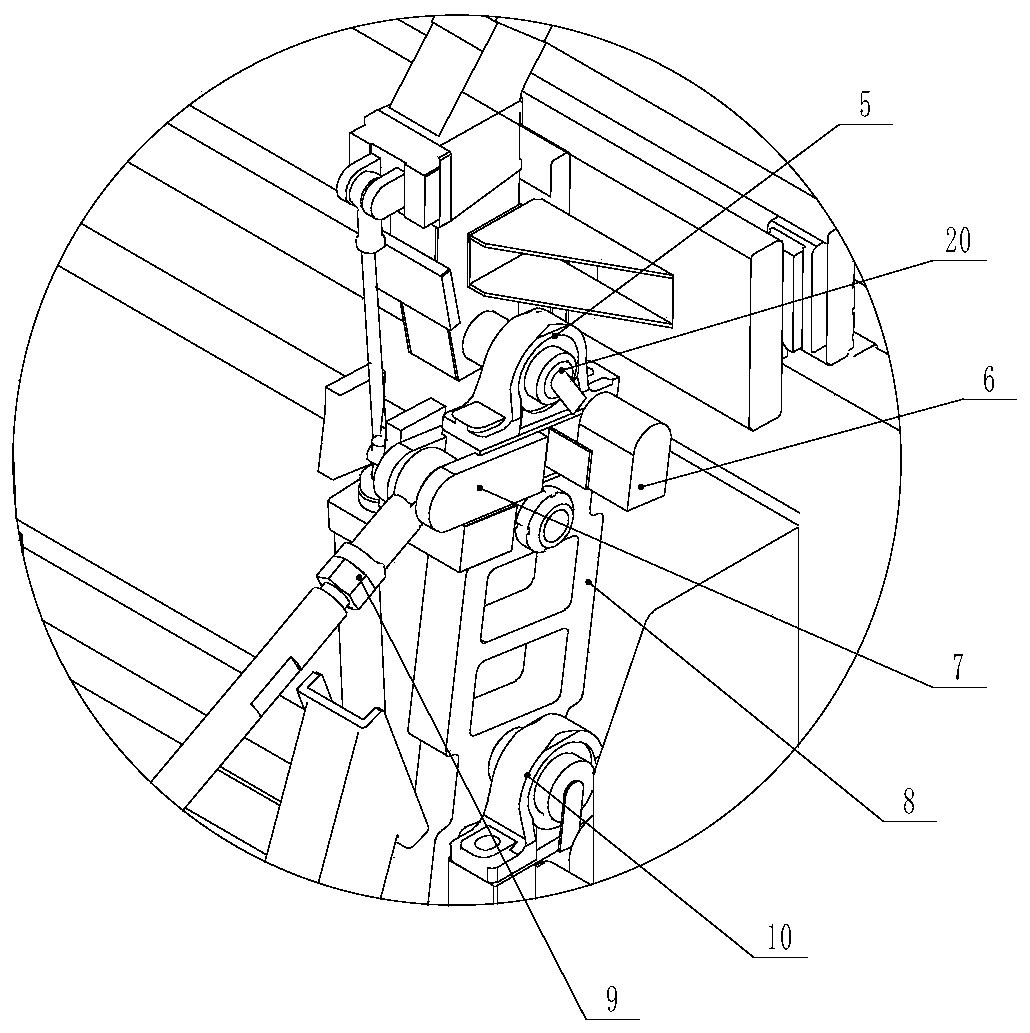

[0026] The canned product line swing device includes a clamping mechanism and a power mechanism. The clamping mechanism is connected to the swing arm 8 through the centripetal bearing seat 5, and the swing arm 8 is connected to the frame through the bearing seat 10. The power mechanism The fisheye bearing 9 is connected with the hinge base I7, and the hinge base I7 is fixed on the swing arm 8.

Embodiment 2

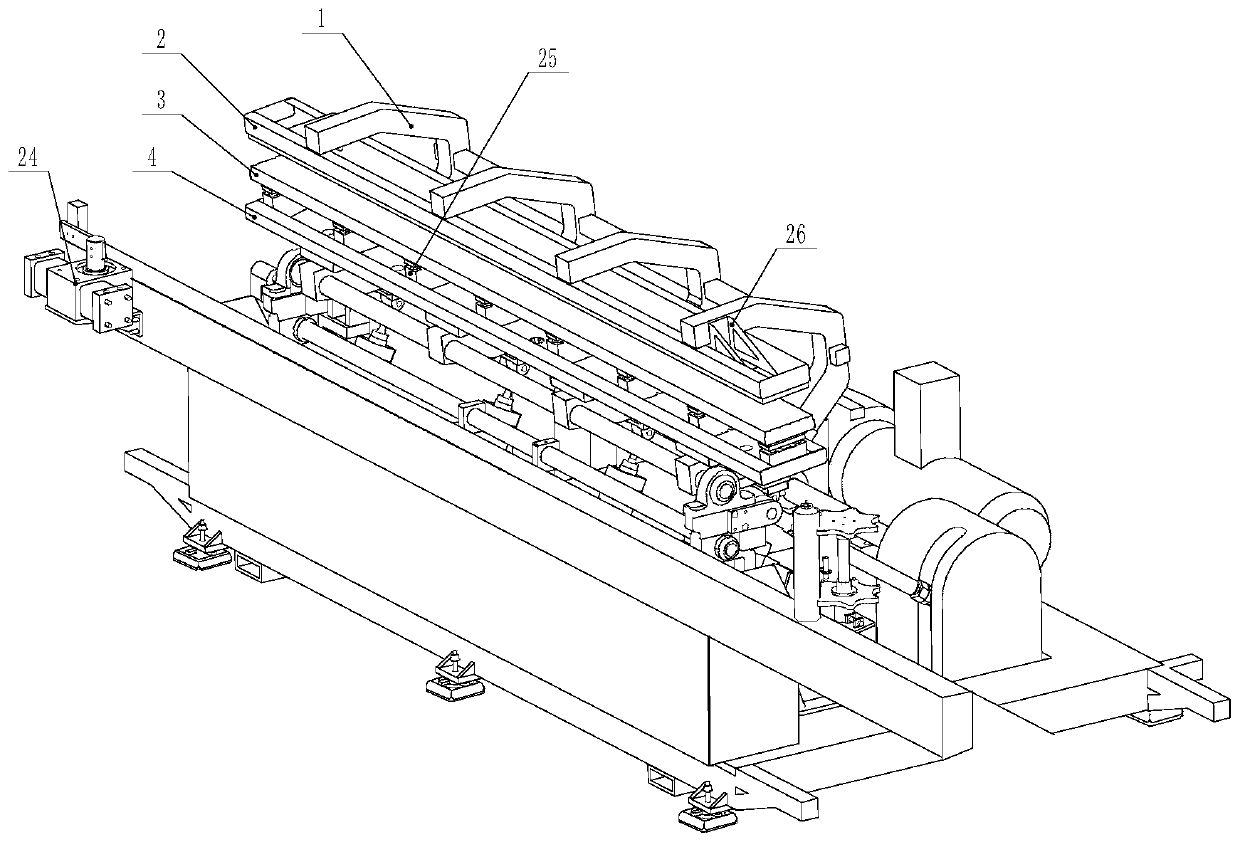

[0028] The canned product line swing device includes a clamping mechanism and a power mechanism. The clamping mechanism is connected to the swing arm 8 through the centripetal bearing seat 5, and the swing arm 8 is connected to the frame through the bearing seat 10. The power mechanism The fisheye bearing 9 is connected with the hinge base I7, and the hinge base I7 is fixed on the swing arm 8. The clamping mechanism is provided with a hinge seat II17, and the hinge seat II17 is connected with the fixed rod 23 arranged on the frame through the telescopic device I16. The clamping mechanism includes an upper clamping plate 2, a push plate 3 and a push plate fixing plate 4. A telescopic device II 25 is arranged between the push plate 3 and the pushing plate fixing plate 4. The upper clamping plate 2 and the push plate fixing plate 4 are connected by a connecting piece 1.

Embodiment 3

[0030] The canned product line swing device includes a clamping mechanism and a power mechanism. The clamping mechanism is connected to the swing arm 8 through the centripetal bearing seat 5, and the swing arm 8 is connected to the frame through the bearing seat 10. The power mechanism The fisheye bearing 9 is connected with the hinge base I7, and the hinge base I7 is fixed on the swing arm 8. The clamping mechanism is provided with a hinge seat II17, and the hinge seat II17 is connected with the fixed rod 23 arranged on the frame through the telescopic device I16. The clamping mechanism includes an upper clamping plate 2, a push plate 3 and a push plate fixing plate 4. A telescopic device II 25 is arranged between the push plate 3 and the pushing plate fixing plate 4. The upper clamping plate 2 and the push plate fixing plate 4 are connected by a connecting piece 1.

[0031] There are two or more connecting pieces 1, and the connecting pieces 1 are connected by connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com