Porphyra piece-by-piece feeder

A feeder and seaweed technology, which is applied in pile separation, object separation, thin material processing, etc., can solve the problems that the deep processing of seaweed cannot be applied well in specific occasions, the work reliability is not good, and the dish is served. Achieve fast and continuous supply, accurate coverage, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

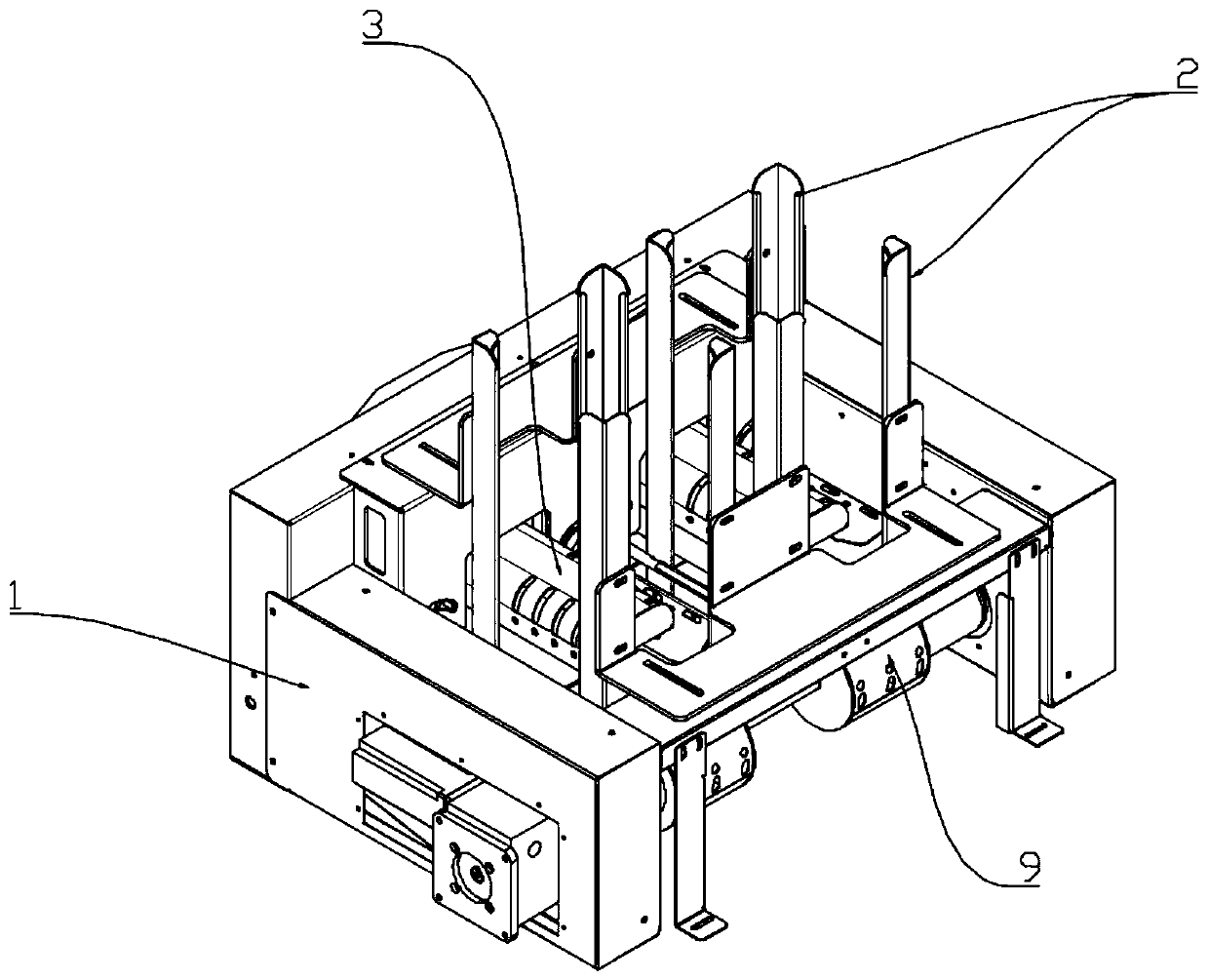

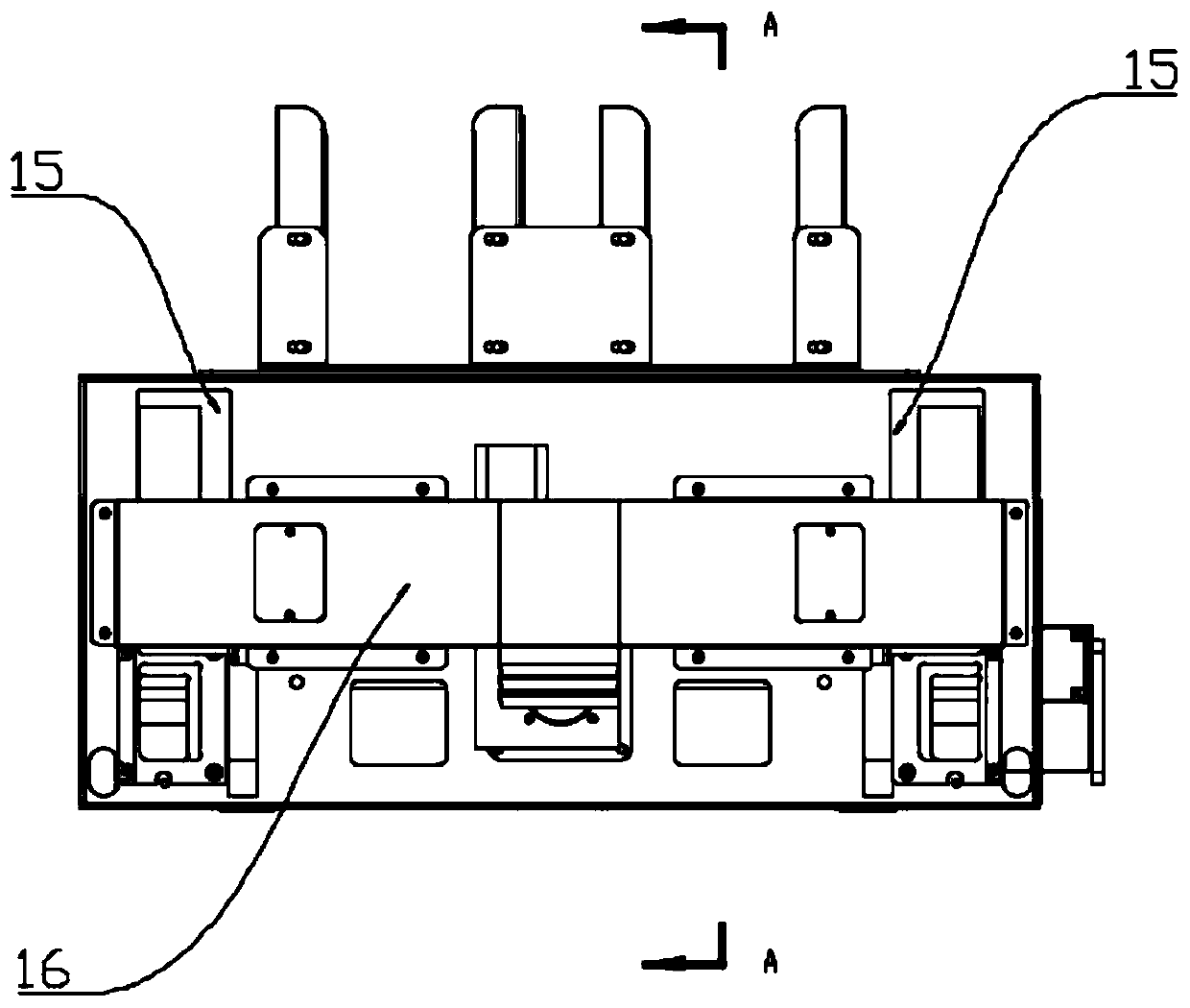

[0039] refer to figure 1 , combined with Figure 5 , a laver paging feeder, comprising a frame 1, on the frame 1 is provided with a material rack 2 for holding the laver sheet family, and the material rack 2 surrounds a vertically arranged material suitable for the shape of the laver sheet. Chamber 201, the bottom of the material rack 2 is provided with a blanking port 202 communicating with the material chamber 201;

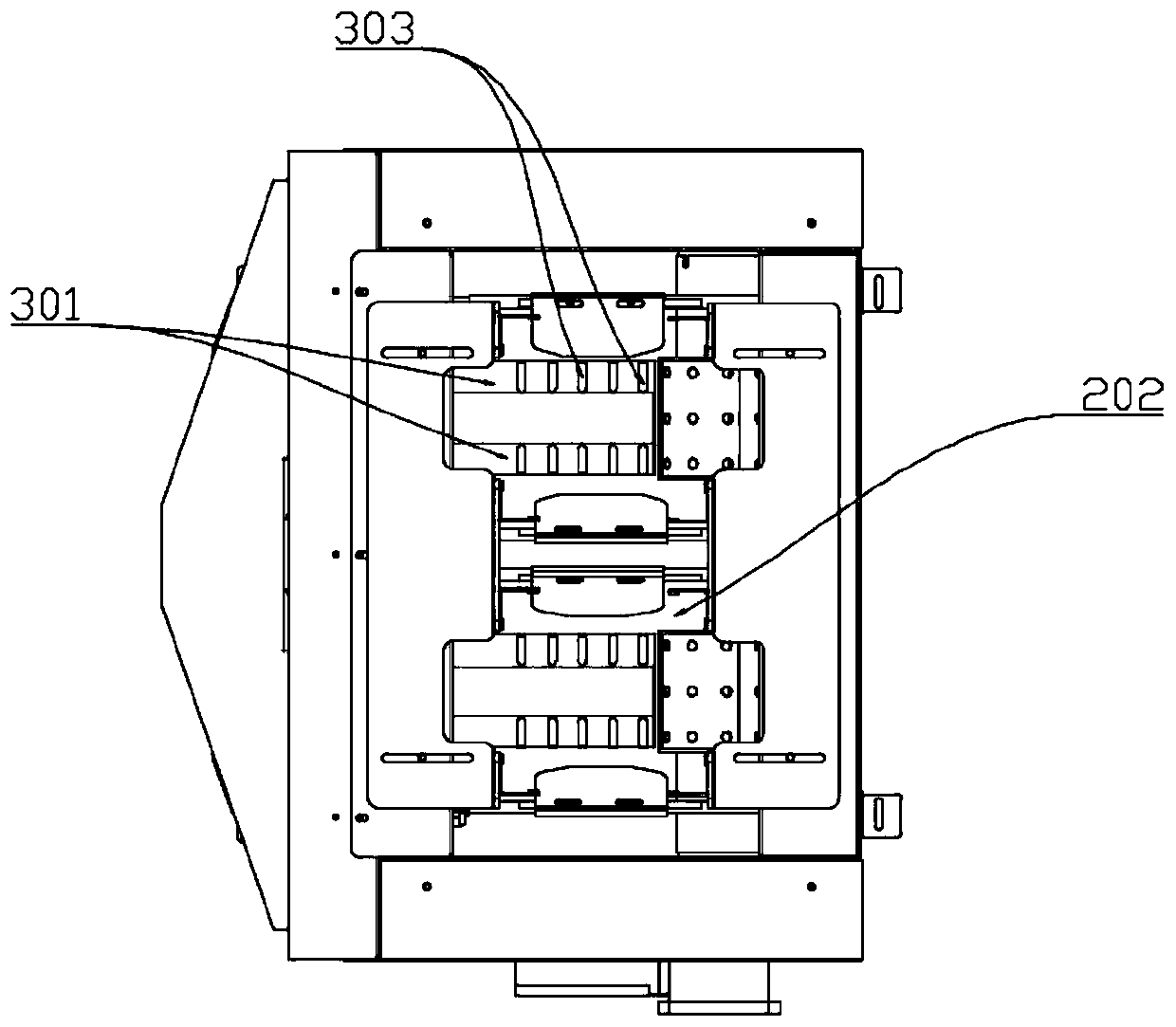

[0040]combine figure 2 , a laver sheet separation device is provided in the blanking port 202, and the laver sheet separation device includes a lifting air head assembly for separating the bottom layer of laver sheets in the lateral adsorption material chamber 201 from the laver sheet group and The rotary air head assembly is used to longitudinally absorb the sheets of laver released by the lifting air head assembly and turn over the material to realize the laver page feeding; the rotating air head assembly and the lifting air head assembly are arranged side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com