Semiconductor workpiece double-sided detection device

A detection device, semiconductor technology, applied in the direction of comprehensive factory control, sorting, etc., can solve the problems of low use efficiency, automatic turning of workpieces, detection accuracy and efficiency reduction, etc., achieve a high degree of automation, improve detection accuracy, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

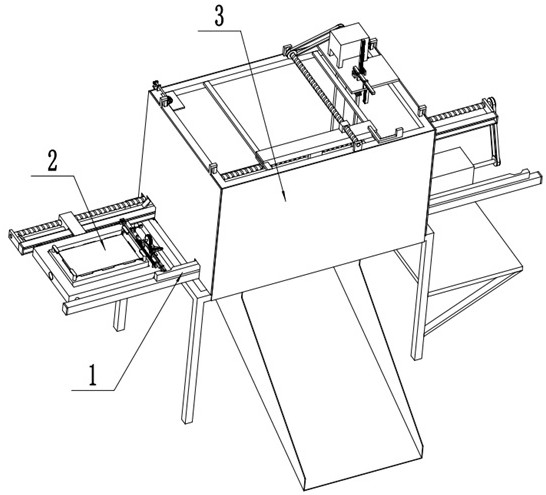

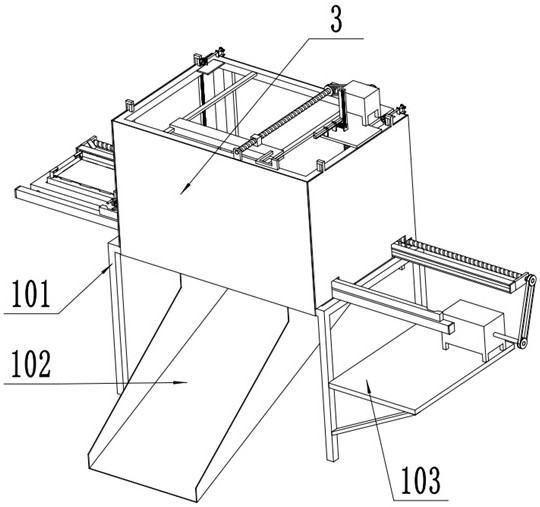

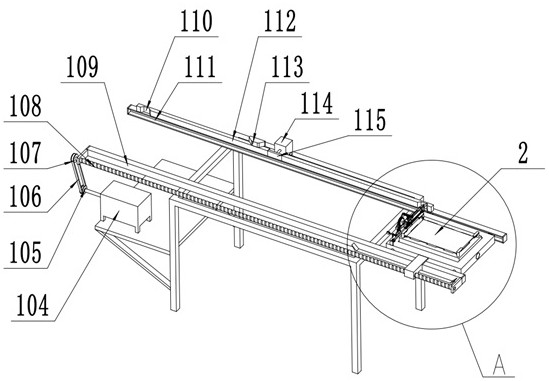

[0037] Example: as figure 1 , figure 2 , Figure 5 As shown, a double-sided detection device for a semiconductor workpiece includes a frame assembly 1, an installation assembly 2 and a detection assembly 3. The detection assembly 3 is arranged on the frame assembly 1, and the installation assembly 2 is slidably installed on the frame assembly 1. The assembly 2 is used to fix the semiconductor workpiece 4, and the mounting assembly 2 realizes the automatic clamping of the semiconductor workpiece 4 through the clamping drive assembly 206 and the clamping action assembly 208 during the sliding process of the mounting assembly 2 on the rack assembly 1. The mounting assembly 2 is mounted on the rack. During the sliding process of the assembly 1, the automatic turning is realized by the inversion driving assembly 207, and the double-sided detection of the semiconductor workpiece 4 is realized. automatically opens.

[0038] like figure 1 , figure 2 image 3 As shown, the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com