Partially thickened product molding equipment for pulp molded products of the same product

A pulp molding and product technology, which is applied in textiles and papermaking, can solve the problems of poor product quality and uneven material thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

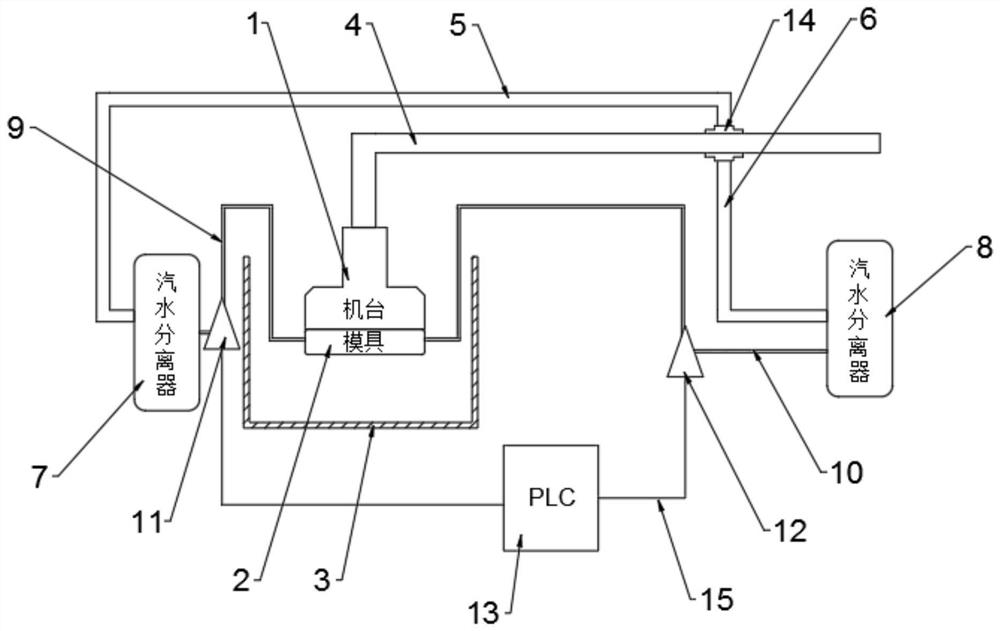

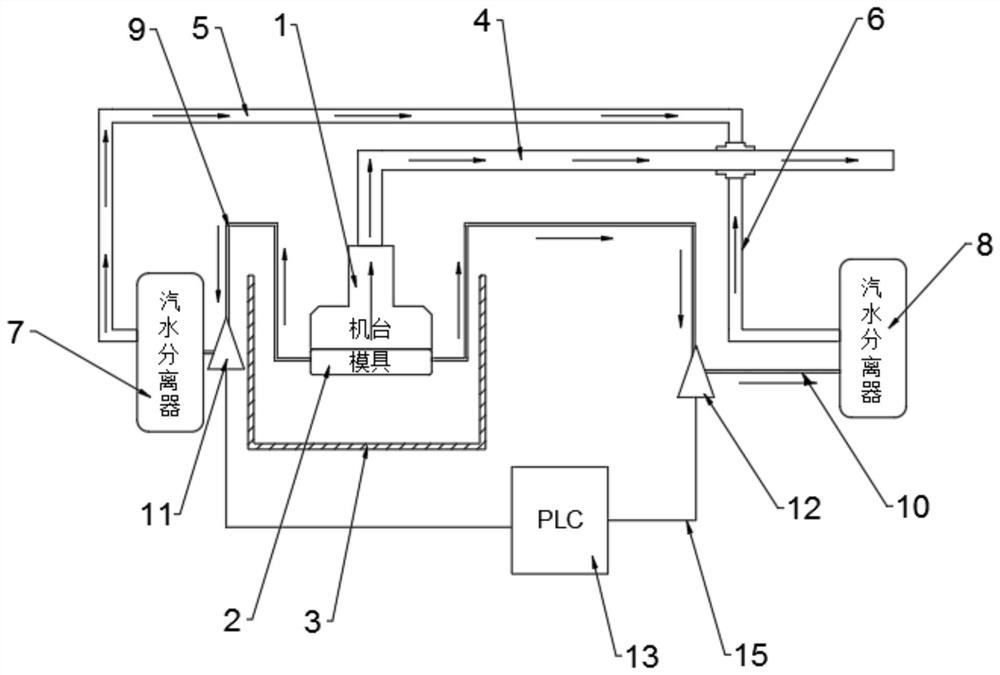

[0022] Embodiment one, by figure 1 and figure 2 Given, the present invention includes a machine 1, a slurry suction mold 2 is installed at the lower end of the machine 1 for sucking raw materials, a slurry pool 3 is connected below the slurry suction mold 2 for accommodating raw materials, the upper end of the machine 1 is connected with a large Vacuum pipeline 4, the upper and lower sides of one end of the large vacuum pipeline 4 are connected with a first vacuum branch pipe 5 and a second vacuum branch pipe 6 for extracting vacuum, and one end of the first vacuum branch pipe 5 and the second vacuum branch pipe 6 are respectively connected There are a first steam-water separator 7 and a second steam-water separator 8 to prevent moisture from being sucked into the large vacuum pipeline 4 for steam-water separation. One end of the first steam-water separator 7 and the second steam-water separator 8 are respectively connected through the first The pipe 9 and the second connect...

Embodiment 2

[0023] Embodiment 2, on the basis of Embodiment 1, the first vacuum branch pipe 5 and the second vacuum branch pipe 6 are connected to the large vacuum pipe 4 through a four-way joint 14 for connecting the pipes.

Embodiment 3

[0024] Embodiment three, on the basis of embodiment two, the four-way joint 14 and the first vacuum branch pipe 5, the second vacuum branch pipe 6 and the large vacuum pipe 4 are connected with sealing rings to avoid air leakage at the joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com