An electro-hydraulic servo valve triple redundancy coil structure

An electro-hydraulic servo valve and three-redundancy technology, applied in the field of mechanical hydraulics, can solve problems such as aircraft out of control, poor working conditions, and loss of life safety, and achieve the effect of increasing control margin and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

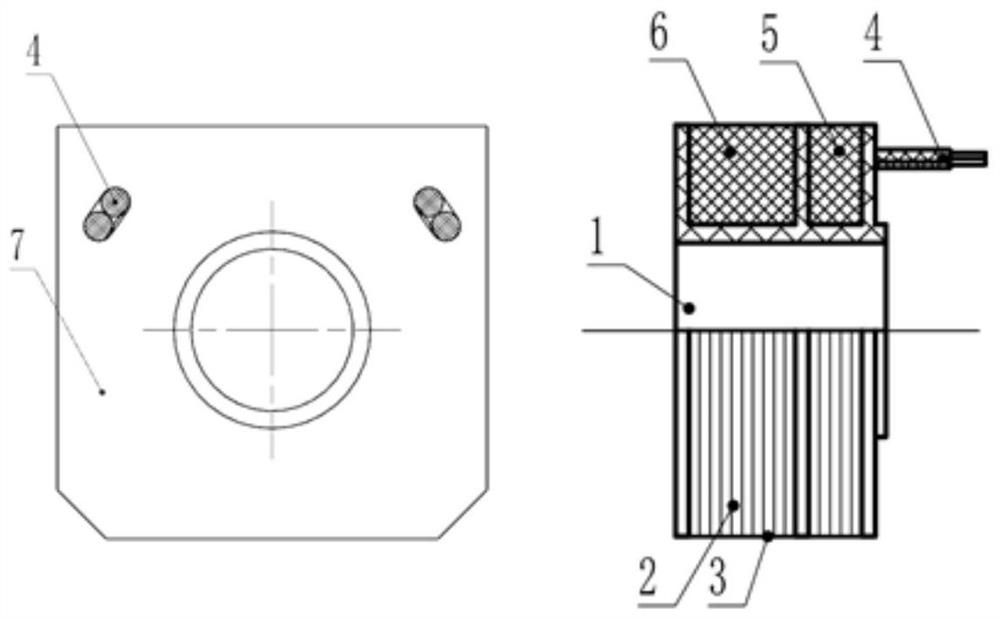

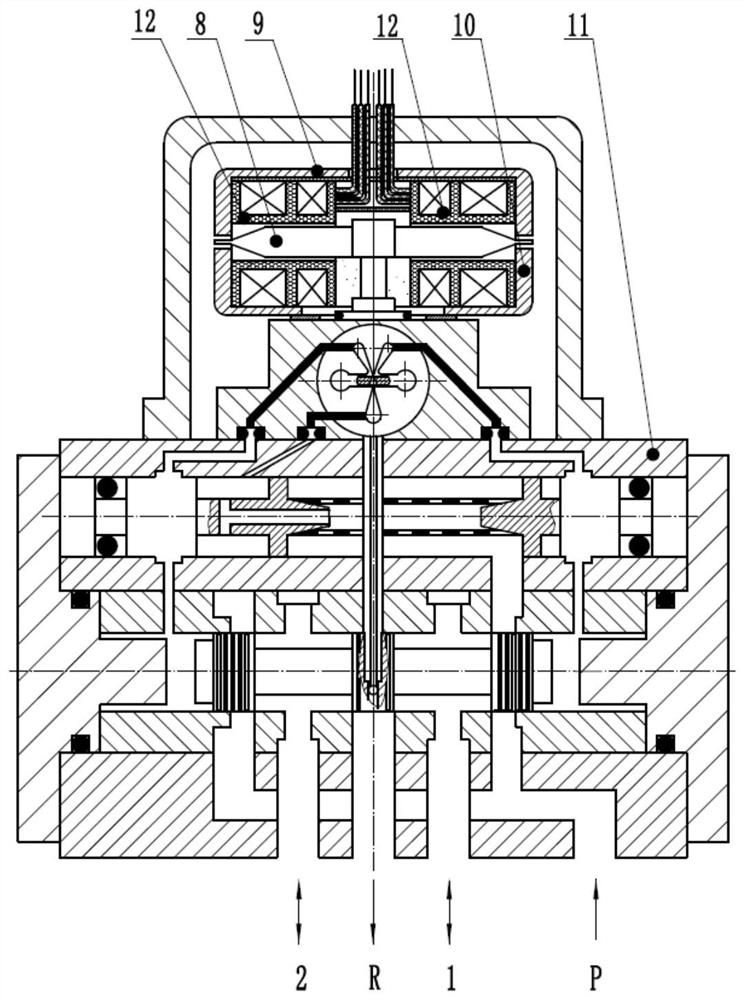

[0019] The three-redundancy coil structure of the electro-hydraulic servo valve of the present invention includes a large winding 6, a small winding 5, a retaining wall, a lead wire 4, and an armature assembly 8. The large winding 6 and the small winding 5 are installed side by side, and the large winding 6 and the small winding 5 are installed side by side. A retaining wall is provided between the small windings 5 to form a coil assembly 12; the two coil assemblies 12 are installed on the two cantilevers of the armature assembly 8; the two small windings 5 are connected in series through lead wires, and the two coil assemblies 12 The small windings 5 are adjacent, and the large windings 6 are arranged at both ends of the armature assembly 8 .

[0020] The large winding 6 and the small winding 5 are made by winding the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com