Negative pressure isolation ward ventilation system and debugging method thereof

A technology of negative pressure isolation and fresh air system, which is applied in the direction of ventilation system, heating and ventilation control system, heating and ventilation safety system, etc. It can solve problems such as unsatisfactory requirements, energy waste, and insufficient number of air changes, so as to ensure air exchange Number of times and negative pressure value, reduced operating energy consumption, and high operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

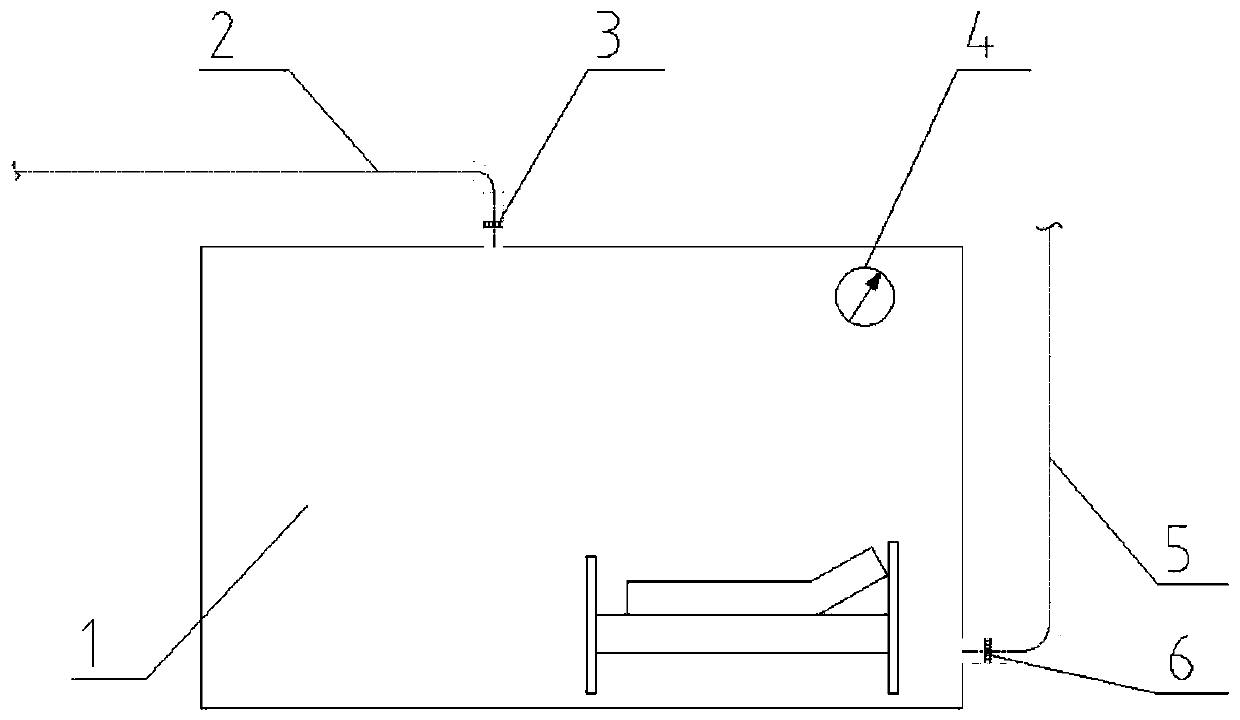

[0020] figure 1 A fresh air system for a negative pressure isolation ward is shown in , comprising a negative pressure isolation ward 1, a fresh air system 2 and an exhaust system 5 communicating with the negative pressure isolation ward; the fresh air system is isolated from the negative pressure A fresh air volume regulating valve 3 is provided between the wards; an exhaust air volume regulating valve 6 is provided between the exhaust system and the negative pressure isolation ward; a negative pressure gauge is provided in the negative pressure isolation ward 5.

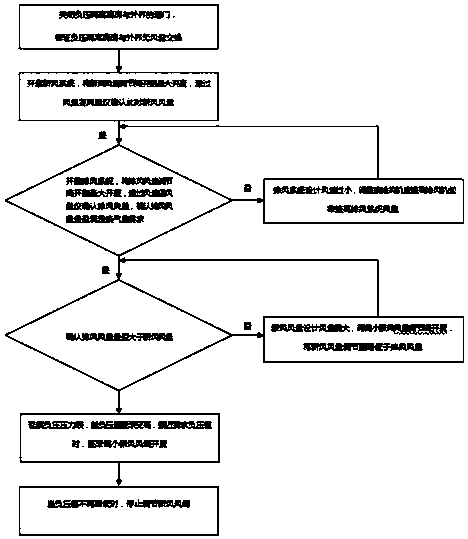

[0021] figure 2 A flow chart showing a debugging method for a fresh air system in a negative pressure isolation ward, including the following steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com