Automatic pipe outer diameter control system

An automatic control system and pipe technology, applied in the field of plastic pipes, to achieve the effects of reducing manual labor, wide application range, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

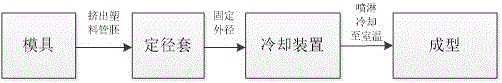

[0024] like figure 1 As shown, the plastic pipe outer diameter shaping process in the prior art is as follows: first, the raw material of the plastic pipe is sent into the mold by the feeding device, and after being melted at high temperature in the mold, the annular pipe is extruded through the mold outlet. The temperature of the pipe is high, and the pipe is easily deformed under the action of gravity and other external forces; after the pipe is sent into the sizing sleeve by the conveying wheel, the negative pressure device of the sizing sleeve is turned on, and the operator is monitoring the negative pressure detection meter next to it. Once the pressure value exceeds the set range, quickly mark this section of pipe, if the pressure value recovers after a period of time, cut off this section of scrap pipe; if the pressure value does not return to the set range after a period of time, shut down the entire production line, and Maintain the temperature in the mold to prevent ...

Embodiment 2

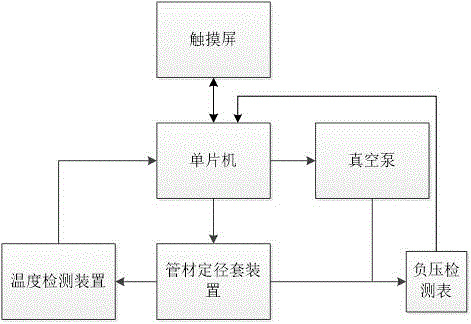

[0026] like figure 2 As shown, a pipe outer diameter automatic control system of the present invention is improved on the basis of the prior art, and its steps are as follows: first, the operator inputs the parameters into the touch screen, starts the system, and the plastic pipe is fed by the feeding device. The raw material is fed into the mold, and after being melted at high temperature in the mold, the ring-shaped pipe is extruded through the mold outlet. Due to the high temperature of the pipe at this time, the pipe is easily deformed under the action of gravity and other external forces; the pipe is sent into the pipe by the conveying wheel The pipe sizing sleeve of the sizing sleeve device, at this time, according to the feedback data such as the negative pressure detection meter and the temperature detection device, the single-chip computer calculates the appropriate negative pressure value, and adjusts the power of the frequency converter on the vacuum pump motor, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com