Light-weight lashing bridge structure of ultra-large container ship

A container ship, super-large technology, applied in deck loading, ship accessories, transportation and packaging, etc., can solve the problems of heavy lashing bridge weight, complex installation process, large shear wall coverage, etc., to achieve weight reduction, reduce the overall Structural weight, saving effect of installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

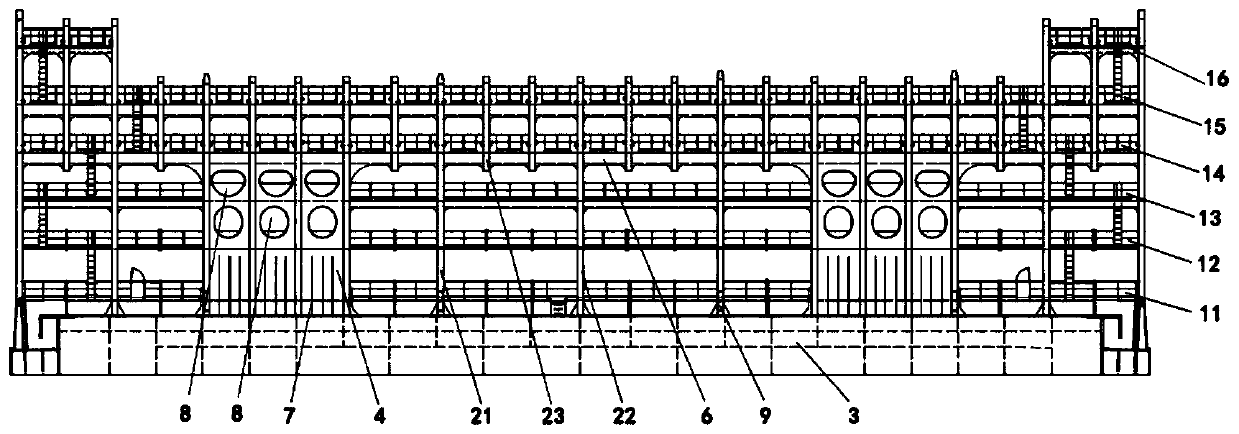

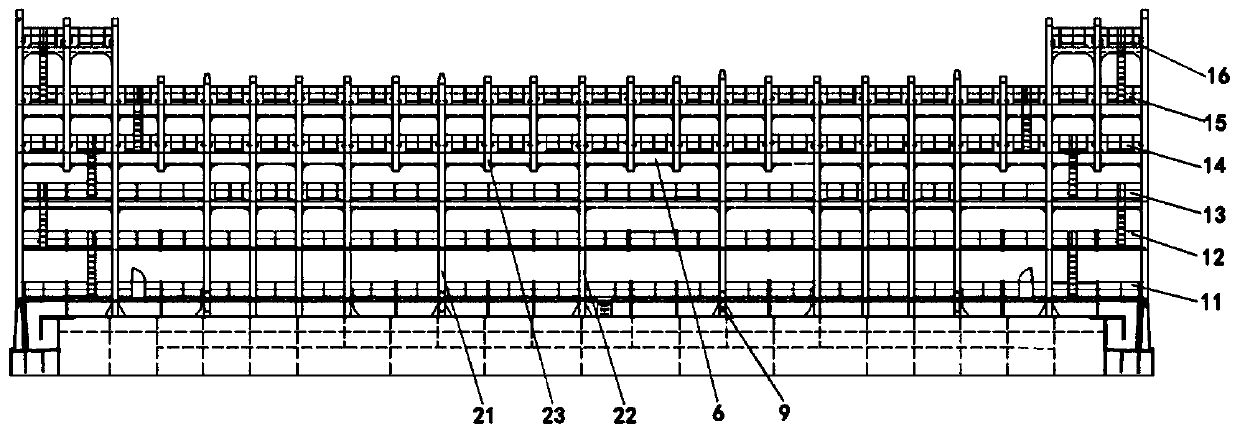

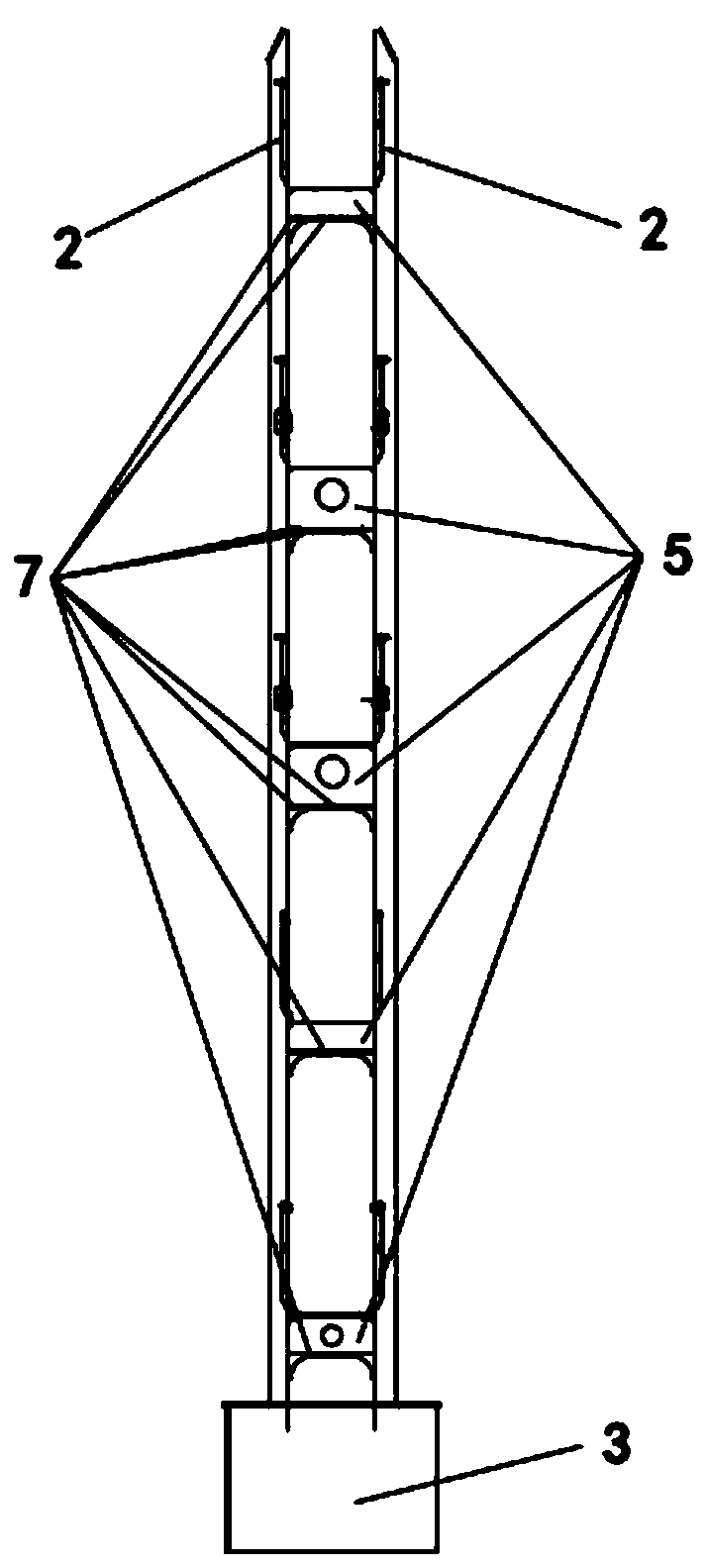

[0035] In a preferred embodiment of the present invention, based on the above-mentioned problems existing in the prior art, a lightweight lashing bridge structure for an ultra-large container ship is now provided, such as figure 1 and figure 2 shown, including:

[0036] Several horizontal platforms are arranged along the ship width direction of the ultra-large container ship, and the horizontal platforms include:

[0037] The first layer of horizontal platform 11, the first layer of horizontal platform 11 is a continuous platform between the port side and the starboard side of an ultra-large container ship;

[0038] The second layer of horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com