Cloth storage dispatching circulating car and working method

A turnover car and cloth technology, applied in the field of warehouse cloth, can solve problems such as low cloth efficiency, and achieve the effect of improving work efficiency and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

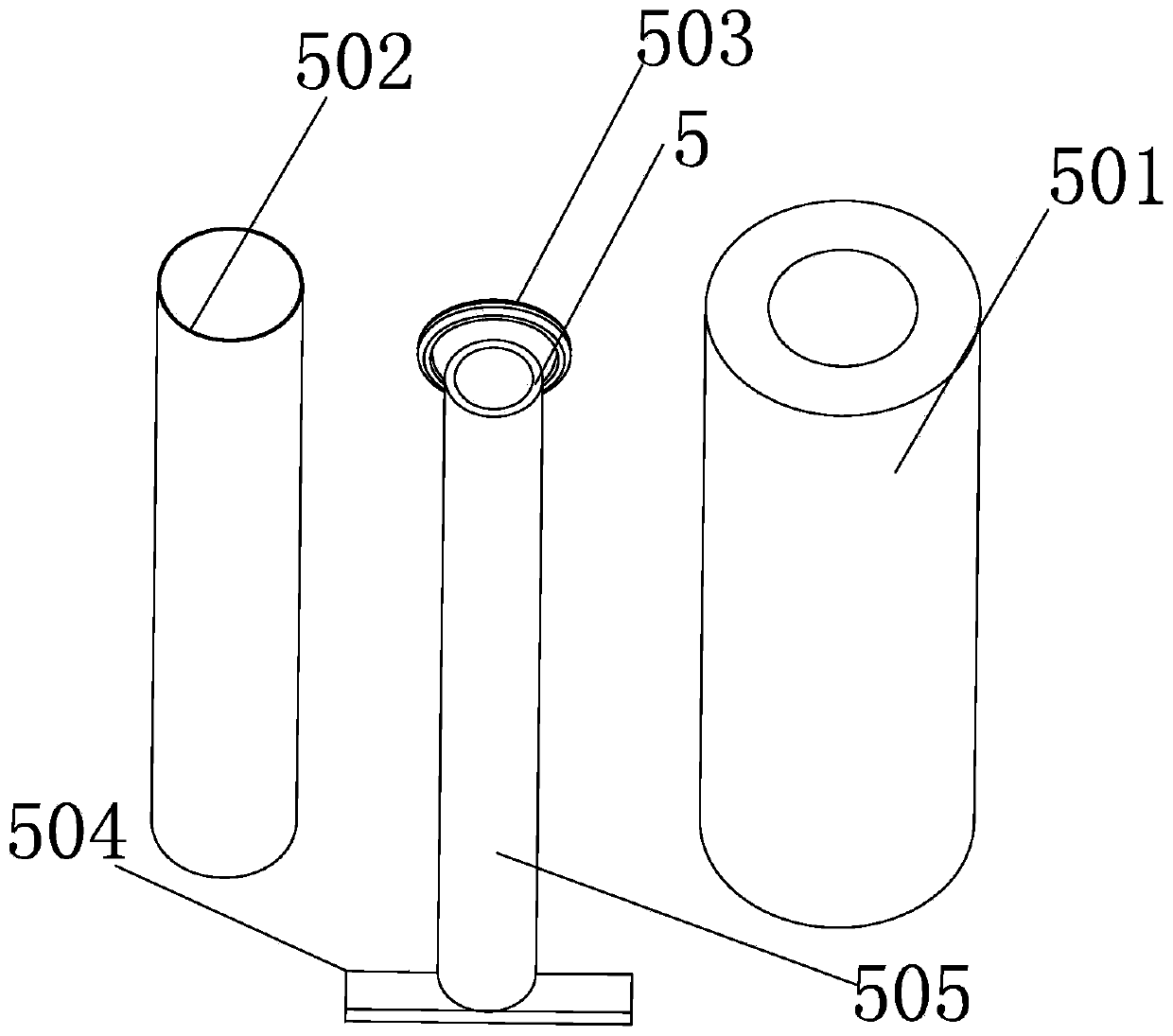

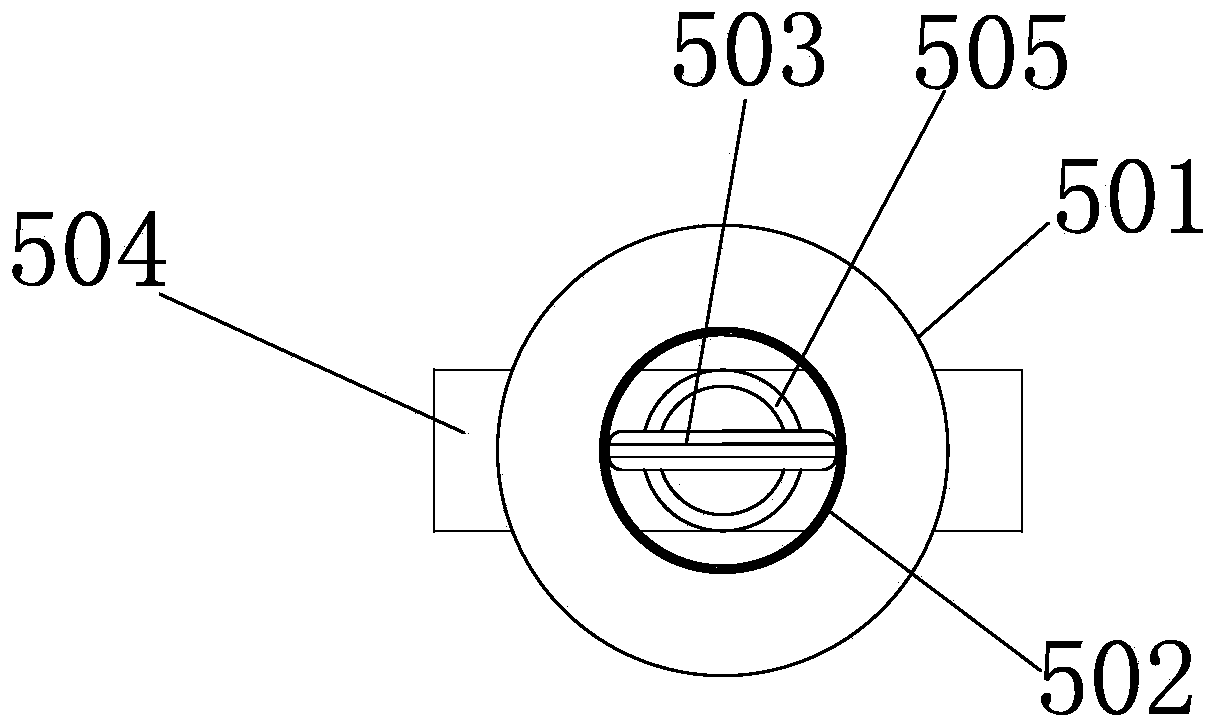

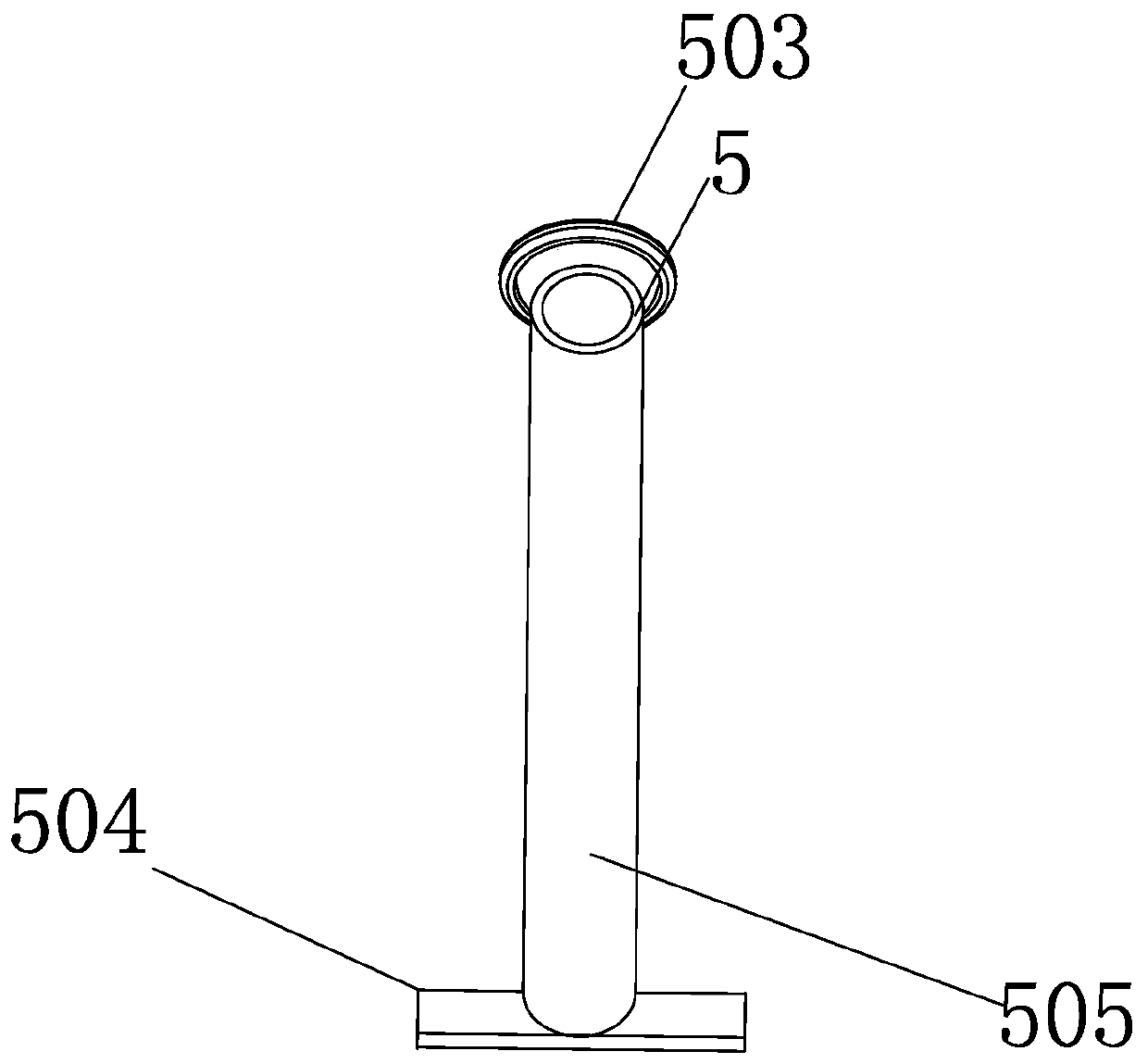

[0055] Such as Figures 1 to 5 As shown, this embodiment firstly provides a cloth storage structure, including a cloth roll and a cloth hanging rod 5 matched therewith; the cloth roll includes a hard paper tube 502 and a cloth 501 wrapped around the outer periphery of the hard paper tube 502; The cloth hanging rod 5 includes a vertically arranged vertical rod 505, and the upper and lower ends of the vertical rod 505 are respectively provided with suspension rings 503 and supporting parts; The upper end of the cardboard tube 502 is exposed, and the supporting part is supported by the cardboard tube 502 and the lower end of the cloth 501. In this embodiment, the supporting part is a cross bar 504.

[0056] This embodiment firstly provides a storage structure that can suspend the cloth roll, which is different from the previous storage method and structure that is laid flat; Wrap around the hard paper tube 502, and then hang it with the cloth hanging rod 5; specifically, the sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap