Turbine shroud including cooling passages in communication with collection plenums

A technology of turbine shroud and cooling channel, applied in mechanical equipment, engine manufacturing, engine function, etc., can solve problems such as ineffectiveness and unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

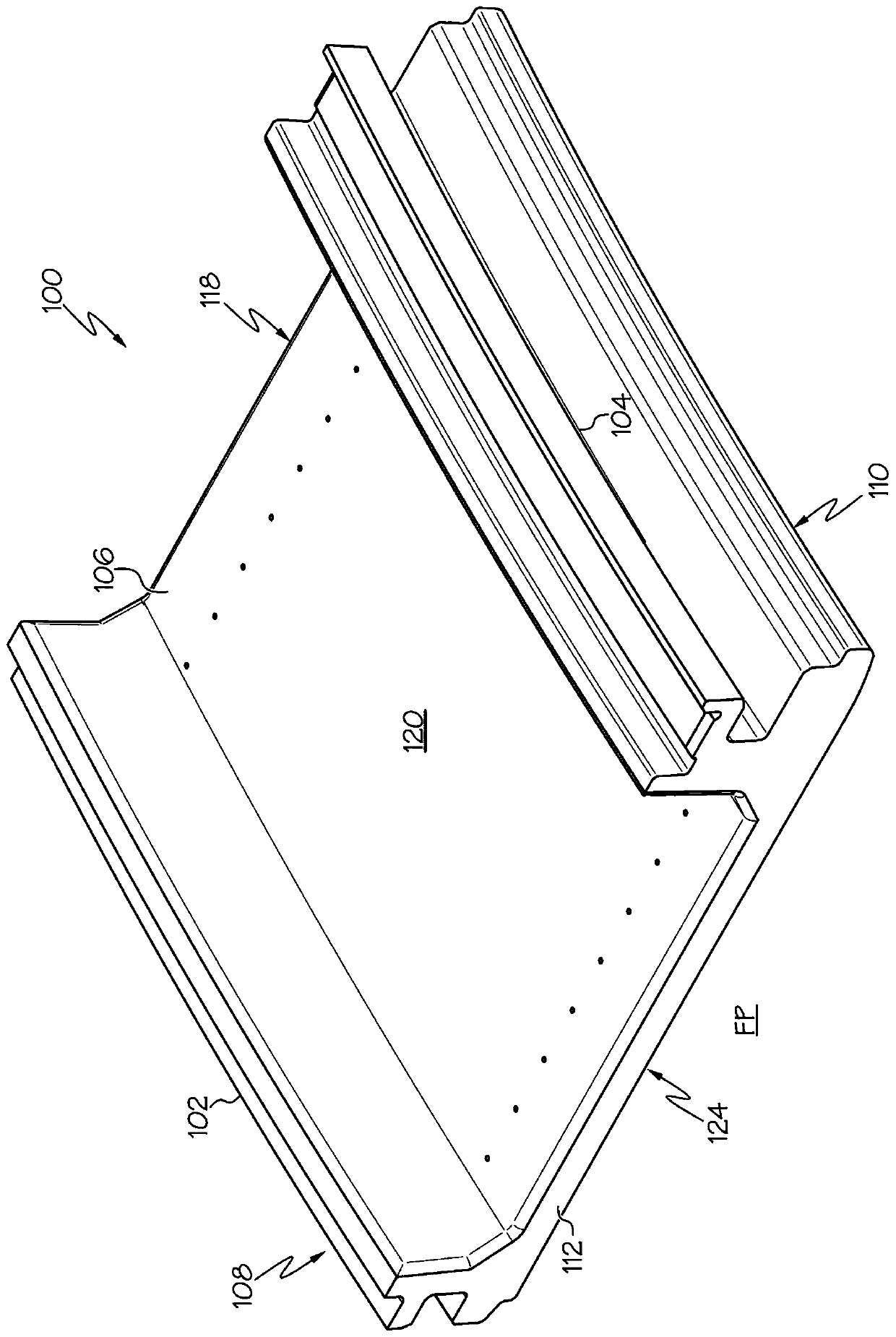

Embodiment Construction

[0041] First, in order to clearly describe the present disclosure, it will be necessary to select certain terms when referring to and describing relevant machine components within the scope of the present disclosure. In doing so, common industry terminology will be used and adopted, where possible, in a manner consistent with its accepted meaning. Unless otherwise indicated, such terms should be given the broadest interpretation consistent with the context of the present application and the scope of the appended claims. Those of ordinary skill in the art will appreciate that several different or overlapping terms may often be used to refer to a particular component. An object that may be described herein as a single part may comprise and be referred to in another context as consisting of multiple parts. Alternatively, an object that may be described herein as comprising multiple components may be referred to elsewhere as a single part.

[0042] In addition, several descripti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com