Optical imaging lens

An optical imaging lens and imaging technology, applied in the lens field, can solve the problems of low relative illumination at the edge of the imaging surface, low pixel value, blue-purple fringe, etc., and achieve good image color reproduction, high unit pixel ratio, and uniform relative illumination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

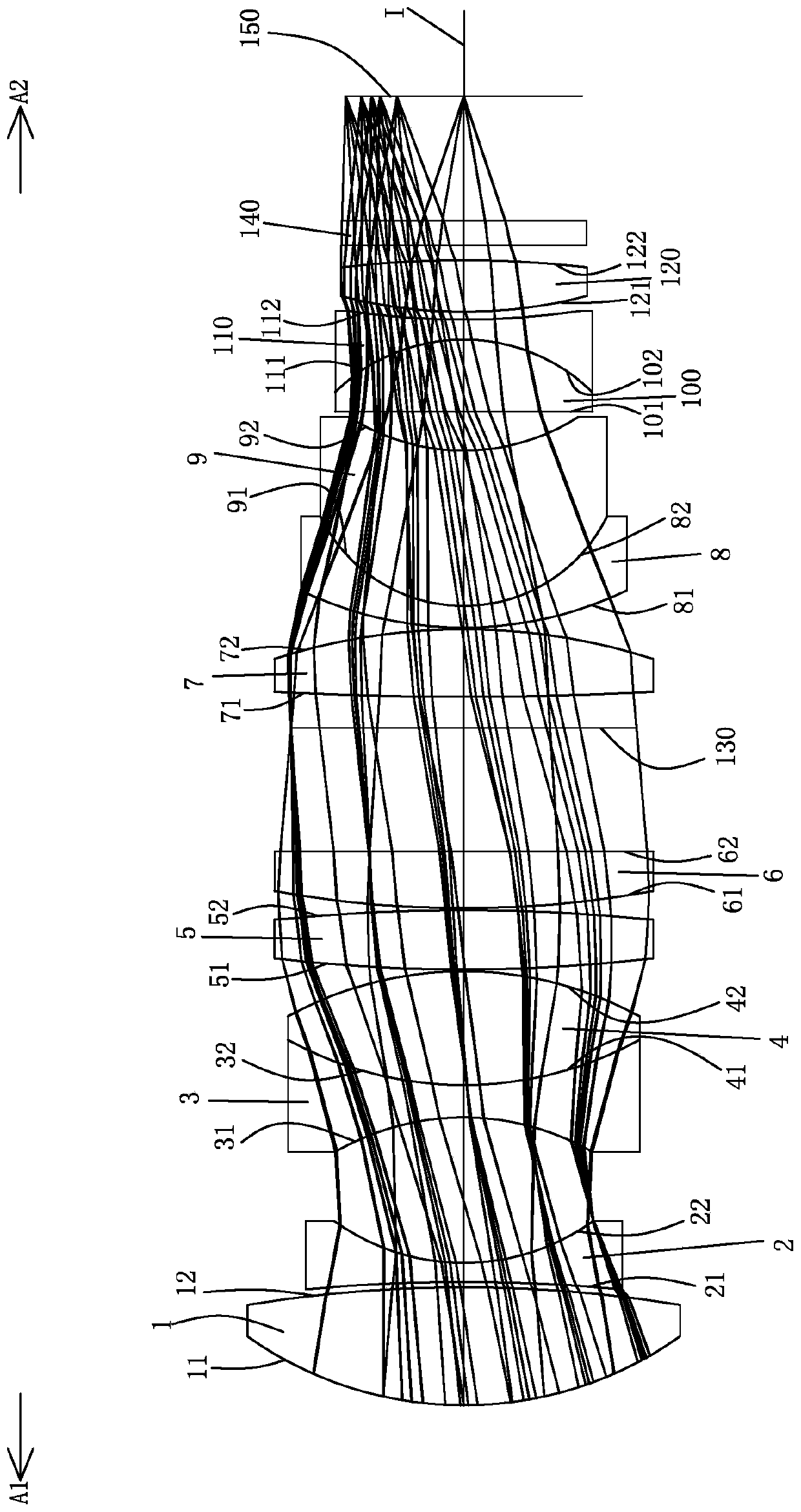

[0103] Such as Figure 7 As can be seen, the concave-convex surface and refractive index of each lens in this embodiment and the first embodiment are the same, and only the optical parameters such as the radius of curvature of the lens surface and the thickness of the lens are different.

[0104] The detailed optical data of this specific embodiment are shown in Table 2-1.

[0105] Detailed optical data of Table 2-1 Example 2

[0106]

[0107]

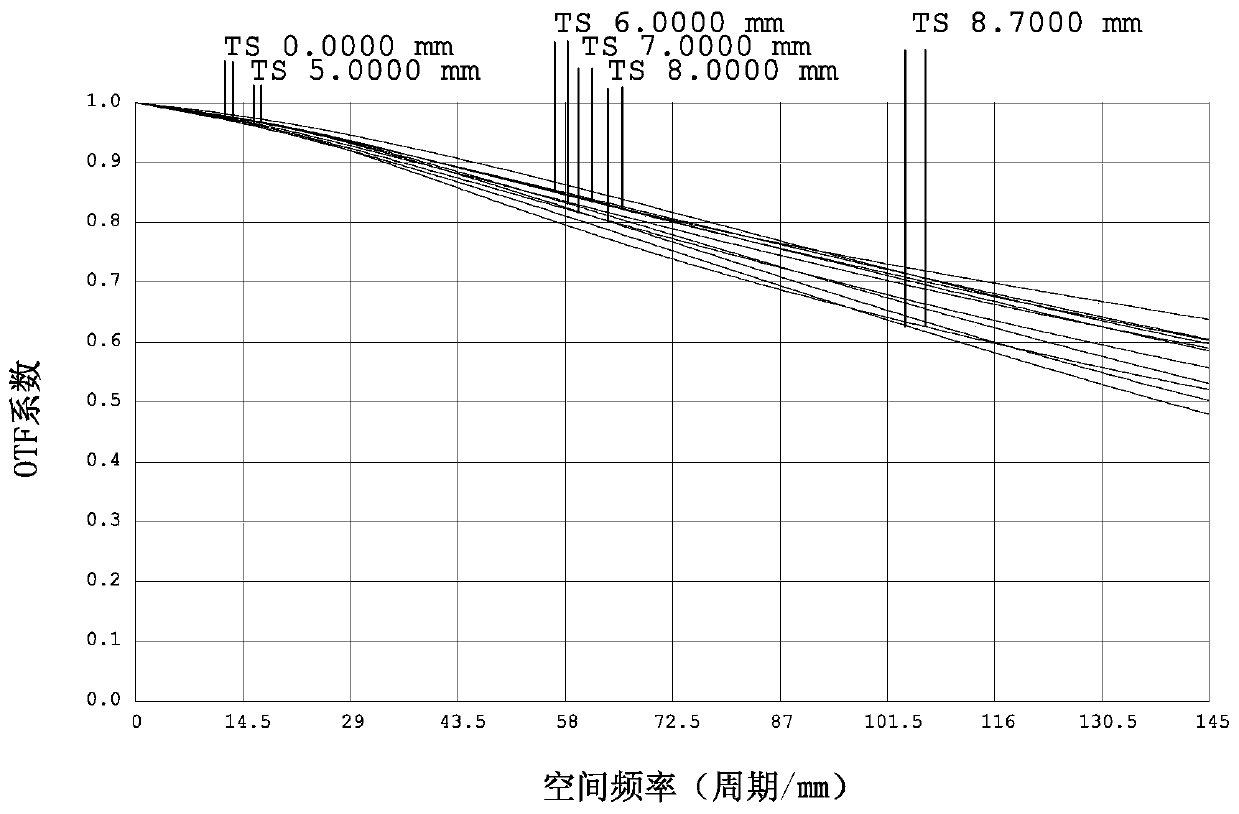

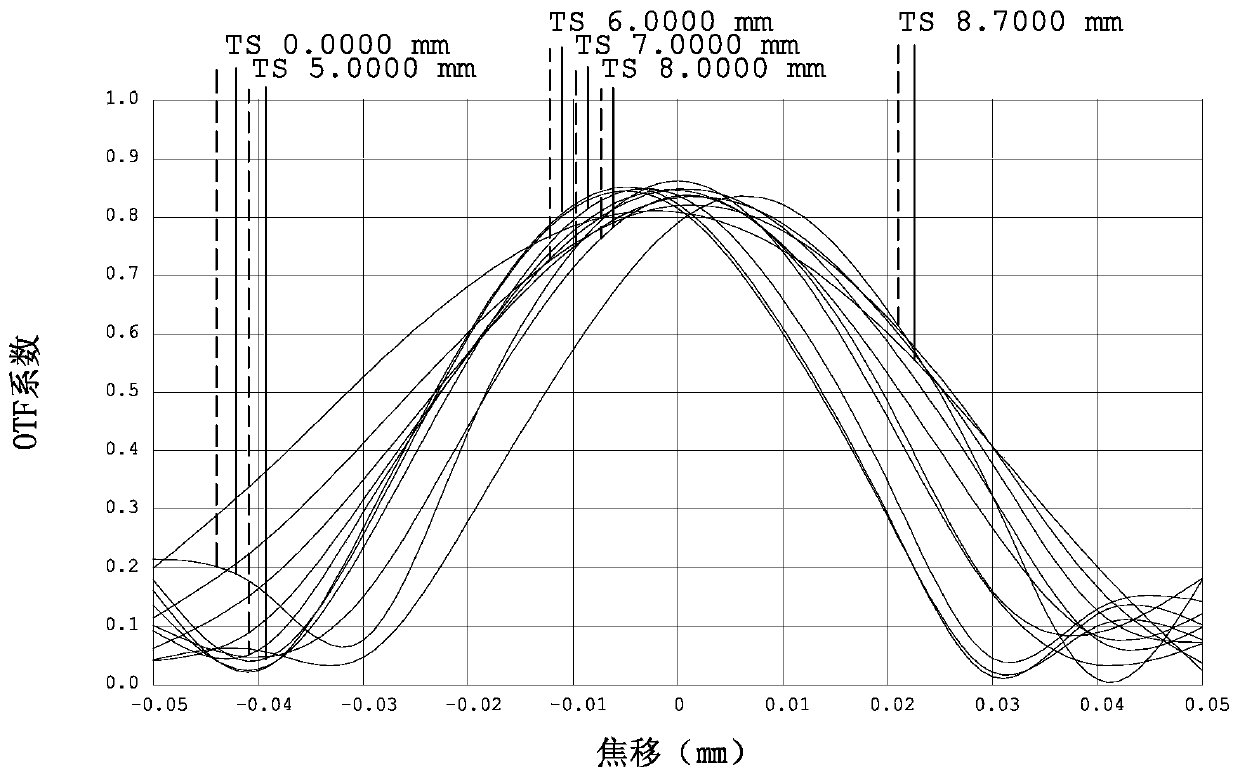

[0108] For the MTF curve of visible light in this specific embodiment, please refer to Figure 8 , it can be seen from the figure that the unit pixel ratio is high. Under the visible light environment, the MTF value at the spatial frequency of 145lp / mm is greater than 0.4, which meets the requirements of picture definition; for the defocus curve of visible light, please refer to Figure 9 , it can be seen that the image quality is uniform; for the relative illuminance of visible light, please refer to Figure 10 , it can be se...

Embodiment 3

[0111]Such as Figure 13 As shown, the surface concave-convex and refractive power of each lens in this embodiment and the first embodiment are approximately the same, only the image side 12 of the first lens 1 is a concave surface, the object side 21 of the second lens 2 is a convex surface, and the seventh lens The object side surface 71 of 7 is a concave surface, and the optical parameters such as the radius of curvature and lens thickness of each lens surface are also different.

[0112] The detailed optical data of this specific embodiment are shown in Table 3-1.

[0113] Detailed optical data of the third embodiment of table 3-1

[0114]

[0115]

[0116] For the MTF curve of visible light in this specific embodiment, please refer to Figure 14 , it can be seen from the figure that the unit pixel ratio is high. Under the visible light environment, the MTF value at the spatial frequency of 145lp / mm is greater than 0.4, which meets the requirements of picture clari...

Embodiment 4

[0119] Such as Figure 19 As shown, the surface concave-convex and refractive power of each lens in this embodiment and the first embodiment are approximately the same, only the image side 12 of the first lens 1 is a concave surface, the object side 21 of the second lens 2 is a convex surface, and the seventh lens The object side surface 71 of 7 is a concave surface, and the optical parameters such as the radius of curvature and lens thickness of each lens surface are also different.

[0120] The detailed optical data of this specific embodiment are shown in Table 4-1.

[0121] Table 4-1 Detailed optical data of Example 4

[0122]

[0123]

[0124] For the MTF curve of visible light in this specific embodiment, please refer to Figure 20 , it can be seen from the figure that the unit pixel ratio is high. Under the visible light environment, the MTF value at the spatial frequency of 145lp / mm is greater than 0.4, which meets the requirements of picture clarity; for the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com