Large-light-flux high-resolution flight time measuring lens

A time-of-flight, high-resolution technology, applied in the field of lenses, can solve the problems of large overall size of high-resolution time-of-flight measurement lenses, large sacrifice of illuminance at the edge of the field of view, and not reaching the ideal light transmission value, so as to shorten the total length of the system and improve the Signal utilization and good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

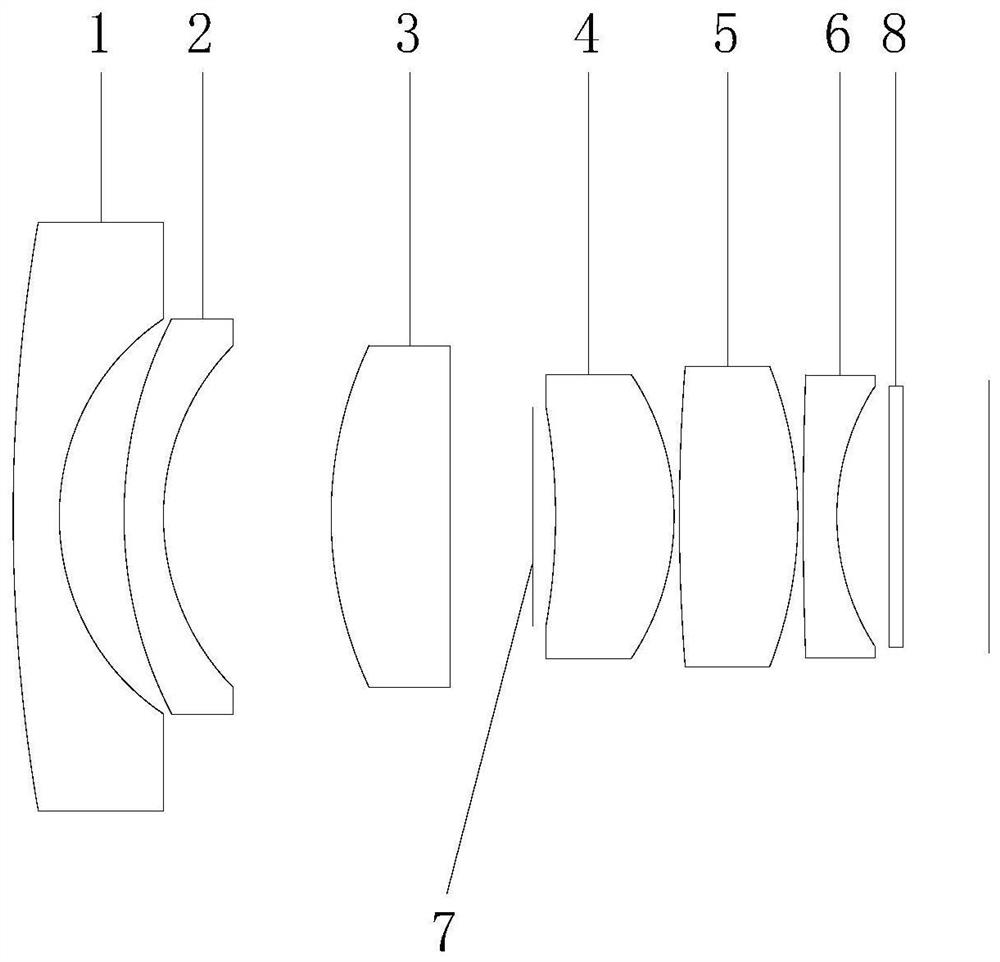

[0094] refer to figure 1 As shown, this embodiment discloses a Datong optical high-resolution time-of-flight measurement lens, which includes a first lens 1 to a sixth lens 6 along an optical axis from the object side to the image side; the first lens 1 to the sixth lens The lenses 6 each include an object side facing the object side and allowing the imaging light to pass through, and an image side facing the image side and allowing the imaging light to pass through;

[0095] The first lens 1 has a negative diopter, the object side of the first lens 1 is convex, and the image side is concave;

[0096] The second lens 2 has a negative diopter, the object side of the second lens 2 is convex, and the image side is concave;

[0097] The third lens 3 has a positive diopter, the object side of the third lens 3 is convex, and the image side is convex or flat;

[0098] The fourth lens 4 has a positive diopter, the object side of the fourth lens 4 is concave, and the image side is co...

Embodiment 2

[0110] Cooperate Figure 6 to Figure 10 As shown, the concave-convex surface and refractive index of each lens in this embodiment and the first embodiment are roughly the same, and the optical parameters such as the radius of curvature of the lens surface and the thickness of the lens are different.

[0111] The detailed optical data of this specific embodiment is shown in Table 2.

[0112] The detailed optical data of table 2 embodiment two

[0113]

[0114]

[0115] In this specific embodiment, the fourth lens 4 adopts a glass aspheric lens, and the detailed data of the parameters of the aspheric surface of the fourth lens 4 please refer to the following table:

[0116] Surface serial number K A4 A6 A8 A10 A12 A14 S8 1.09E+02 -1.42E-02 1.00E-03 -1.13E-03 1.31E-04 1.05E-04 -2.74E-05 S9 -3.75E-01 -4.26E-04 -2.13E-04 -3.44E-05 1.65E-05 -3.47E-06 3.03E-07

[0117] In this specific embodiment, the focal length of the optical imagin...

Embodiment 3

[0120] Cooperate Figure 11 to Figure 15 As shown, the concave-convex surface and refractive power of each lens in this embodiment and the first embodiment are roughly the same, and the optical parameters such as the radius of curvature of the lens surface and the thickness of the lens are different.

[0121] The detailed optical data of this specific embodiment is shown in Table 3.

[0122] The detailed optical data of table 3 embodiment three

[0123] Face number surface radius of curvature thickness material Refractive index Dispersion coefficient focal length half diameter # type R TC glass nd vd EFLX SD 0 subject surface INF 1000 2465.7 1 first lens 17.993 0.700 H-ZLAF4LA 1.91 35.3 -4.3 4.3 2 3.086 1.285 2.8 3 second lens 6.227 0.800 H-ZBAF21 1.72 38.0 -11.4 2.8 4 3.321 1.936 2.3 5 third lens 6.274 1.630 H-ZLAF90 2.00 25.4 6.0 2.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com