A glass cleaning device for glass production

A glass cleaning and glass technology, applied to cleaning methods using liquids, cleaning methods using tools, cleaning flexible objects, etc., can solve the problems of poor cleaning effect, low cleaning efficiency, waste of water resources, etc., to reduce production costs, The effect of expanding the cleaning area and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

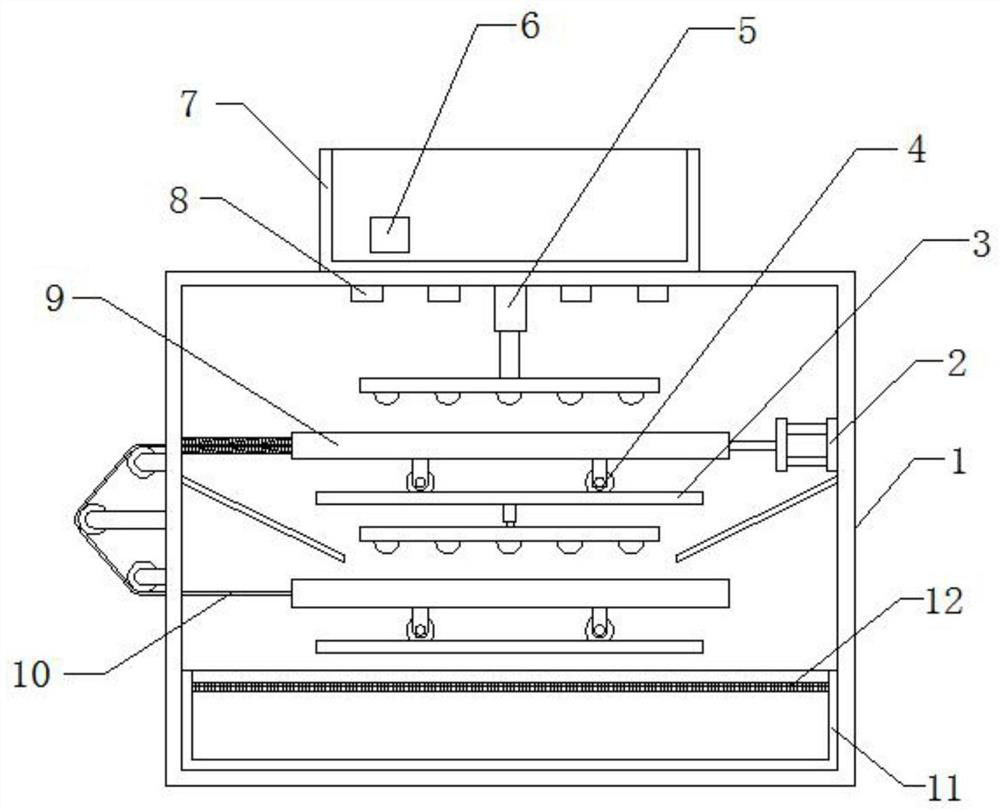

[0025] see figure 1 , the present invention provides a technical solution: a glass cleaning device for glass production, including a cleaning box 1, a first slide rail 3, a first moving wheel 4, a water pump 6, a water tank 7, a nozzle 8, a first placement tank 9, Water collection tank 11 and filter screen 12, the side of the cleaning box 1 is hinged with a box door, the water tank 7 is arranged on the top of the cleaning box 1, the water pump 6 is located inside the cleaning box 1, and the nozzle 8 is arranged in the cleaning box 1 The top, and connected with the water pump 6, the first slide rail 3 is arranged inside the cleaning box 1, and the first storage tank 9 is connected to the first slide rail 3 through the first moving wheel 4. The first storage tank The side end of 9 is in contact with the output shaft of the cylinder, and the other side end of the first storage tank 9 is tightly connected with the inner wall of the cleaning box 1 through a spring. The water pump ...

Embodiment 2

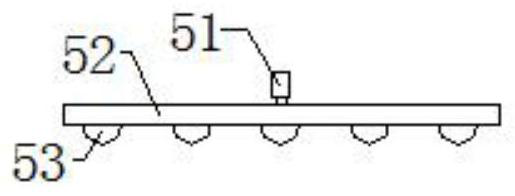

[0029] As a preferred solution of Embodiment 1, please refer to figure 2 , also includes a first auxiliary cleaning mechanism 5, the first auxiliary cleaning mechanism 5 includes an electric telescopic rod 51, a mounting plate 52 and a cleaning roller 53, the output end of the electric telescopic rod 51 is fixedly connected with the mounting plate 52, the The cleaning roller 53 is rotatably connected to the mounting plate 52, and the ring side of the cleaning roller 53 abuts against the glass inside the first storage tank 9. There are several cleaning rollers 53, and several cleaning rollers 53 rotate equidistantly. It is connected to the lower end surface of the mounting plate 52 .

[0030] Working process: adjust the position of the installation plate 52 through the electric telescopic rod 51, the installation plate 52 drives the cleaning roller 53 to move, and makes the cleaning roller 53 contact with the glass inside the first storage tank 9, while the glass moves, the cl...

Embodiment 3

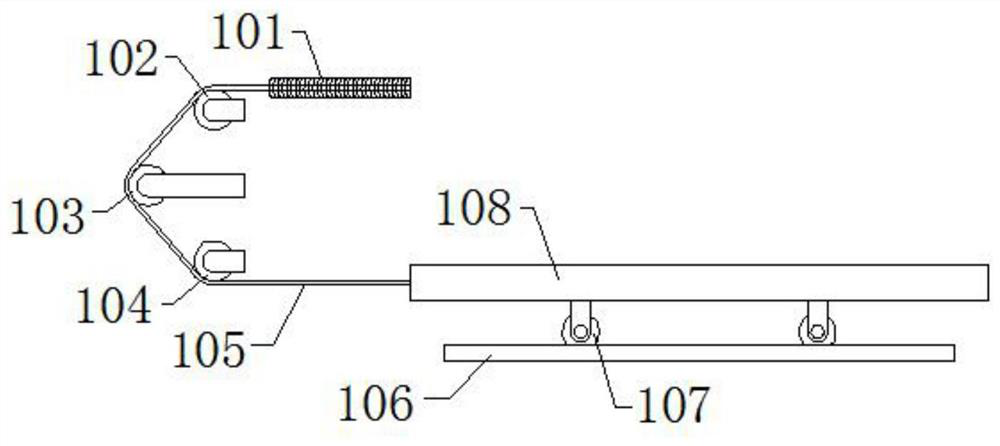

[0032] As another preferred solution of Embodiment 1, please refer to Figure 4 , also includes a drive mechanism 13, the drive mechanism 13 includes a motor 131, a turntable 132, a slide block 133, a connecting rod 134, a pin shaft 135 and a slide bar 136, the motor 131 is arranged inside the cleaning box 1, and the turntable 132 is connected with the The output end of the motor 131 is fixedly connected, and the slide block 133 is connected to the surface of the rotating disk 132 through a pin shaft 135. The slide bar 136 is slidably connected to the inside of the cleaning box 1, and the slide block 133 is slidably connected to the inside of the slide bar 136. The connecting rod 134 is fixed on the sliding bar 136 , and the connecting rod 134 abuts against the first placement groove 9 instead of the output shaft of the air cylinder.

[0033] Work process: cancel the use of the cylinder, run the motor 131, the output end of the motor 131 rotates to drive the turntable 132 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com