Self-locking mechanism for lifting machine

A lift and self-locking technology, which is applied in the direction of lifting frames and lifting devices, can solve problems such as easy slipping of the equipment to be lifted, weak bottom support, and inability to lift, so as to ensure the working stability of the mechanism and increase the Manual operation function, avoiding the effect of sudden drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

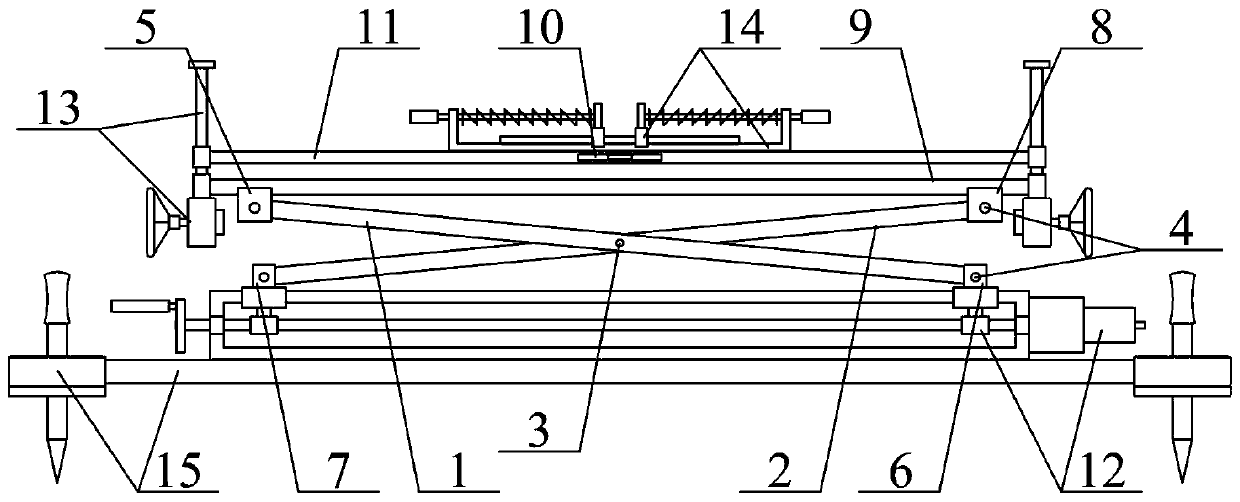

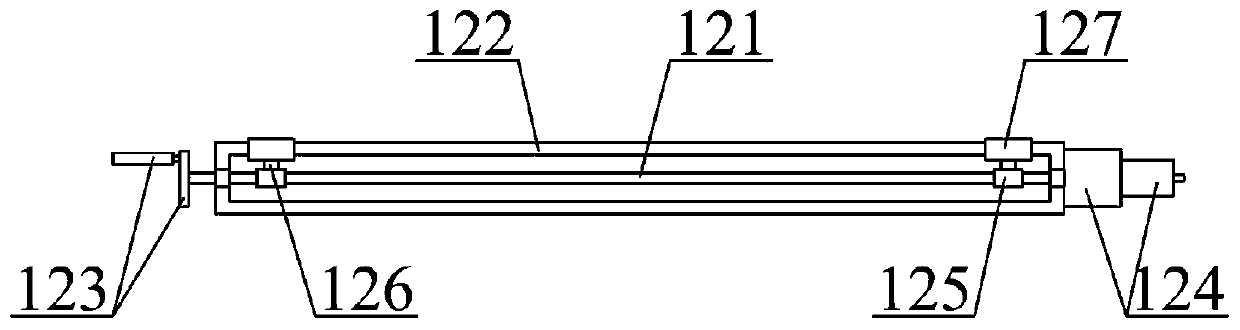

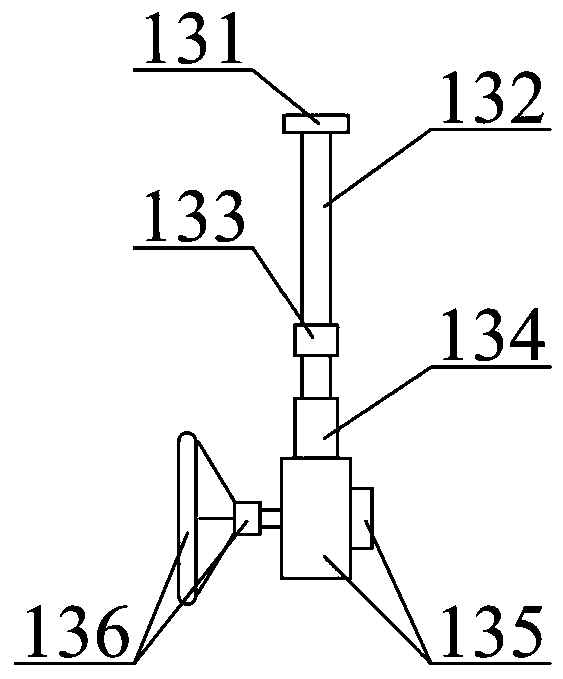

[0038] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the self-locking mechanism for the lift includes the active flat head rod 1, the driven movable flat head rod 2, the movable shaft 3, the connecting shaft 4, the first U-shaped slider 5, and the first mounting seat 6 , the second mounting seat 7, the second U-shaped slider 8, the lifting linear slide rail 9, the horizontal bead 10, the lifting platform 11, the self-locking non-slip lifting rod structure 12, the manual non-electrically operated lifting rod structure 13, which can Adjust the anti-slip lifting clamp structure 14 and the anti-sag bottom support fixed frame structure 15, the joint between the active flat head rod 1 and the driven movable flat head rod 2 is set through the movable shaft 3; the described One end of the active flat head rod 1 is connected to the inner lower end of the first U-shaped slider 5 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com