Self-tightening screw-free nut and automatic tightening and loosening method

A nut and self-tightening technology, which is applied in the direction of friction clamping detachable fasteners, screws, bolts, etc., can solve the problems of time-consuming and cost-consuming, thread rusting, slipping teeth, etc., to improve work efficiency and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

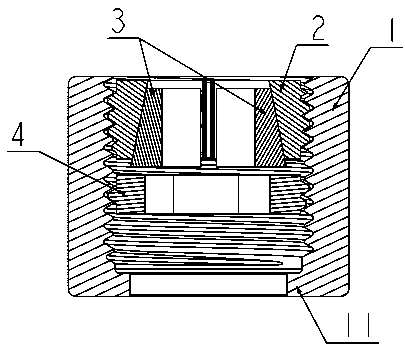

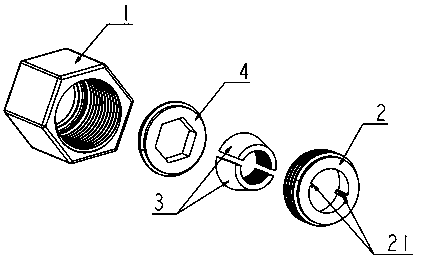

[0034] Example 1, such as figure 1 and 2 The shown self-tightening and thread-free nut of the present invention comprises: an outer nut 1, an intermediate nut 2, a clip 3 and an self-tightening nut 4; the inner side of the outer nut 1 has threads, which are screwed with the outer threads of the intermediate nut 2; The outside of the middle nut 2 has threads, which are screwed together with the inner threads of the outer nut 1. The center of the middle nut 2 has a conical hole; Sliding inside; the outside of the self-tightening nut 4 has a thread, which is screwed with the inner thread of the outer nut 1, and the center of the self-tightening nut 4 has a hole.

Embodiment 2

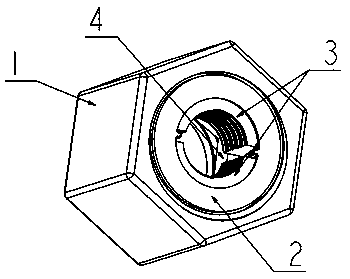

[0035] Example 2, such as figure 1 and 3 The automatic tightening method of self-tightening wire-free nut of the present invention shown, comprises the following steps:

[0036] 1) The screw is inserted from the middle of clip 3;

[0037] 2) Rotate outer nut 1;

[0038] 3) The middle nut 2 rotates relative to the outer nut 1;

[0039] 4) The middle nut 2 drives the clip 3 close to the self-tightening nut 4;

[0040] 5) The clip 3 tightens the self-tightening nut 4 and drives the self-tightening nut 4 to rotate until the outer nut 1 tightens the connected parts and stops rotating.

Embodiment 3

[0041] Example 3, such as figure 1 and 3 The automatic unscrewing method of the self-tightening and wire-free nut of the present invention shown in the present invention comprises the following steps:

[0042] 1) Rotate outer nut 1;

[0043] 2) The middle nut 2 rotates relative to the outer nut 1;

[0044] 3) The middle nut 2 drives the clip 3 away from the self-tightening nut 4;

[0045] 4) The clip 3 slides relative to the middle nut 2 to loosen the clamped screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com