Combined connector

A combined connection and elastic ring technology, applied in the direction of connecting components, threaded fasteners, locking fasteners, etc., can solve the problems of easy falling off, unstable connection between the washer and the nut body, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

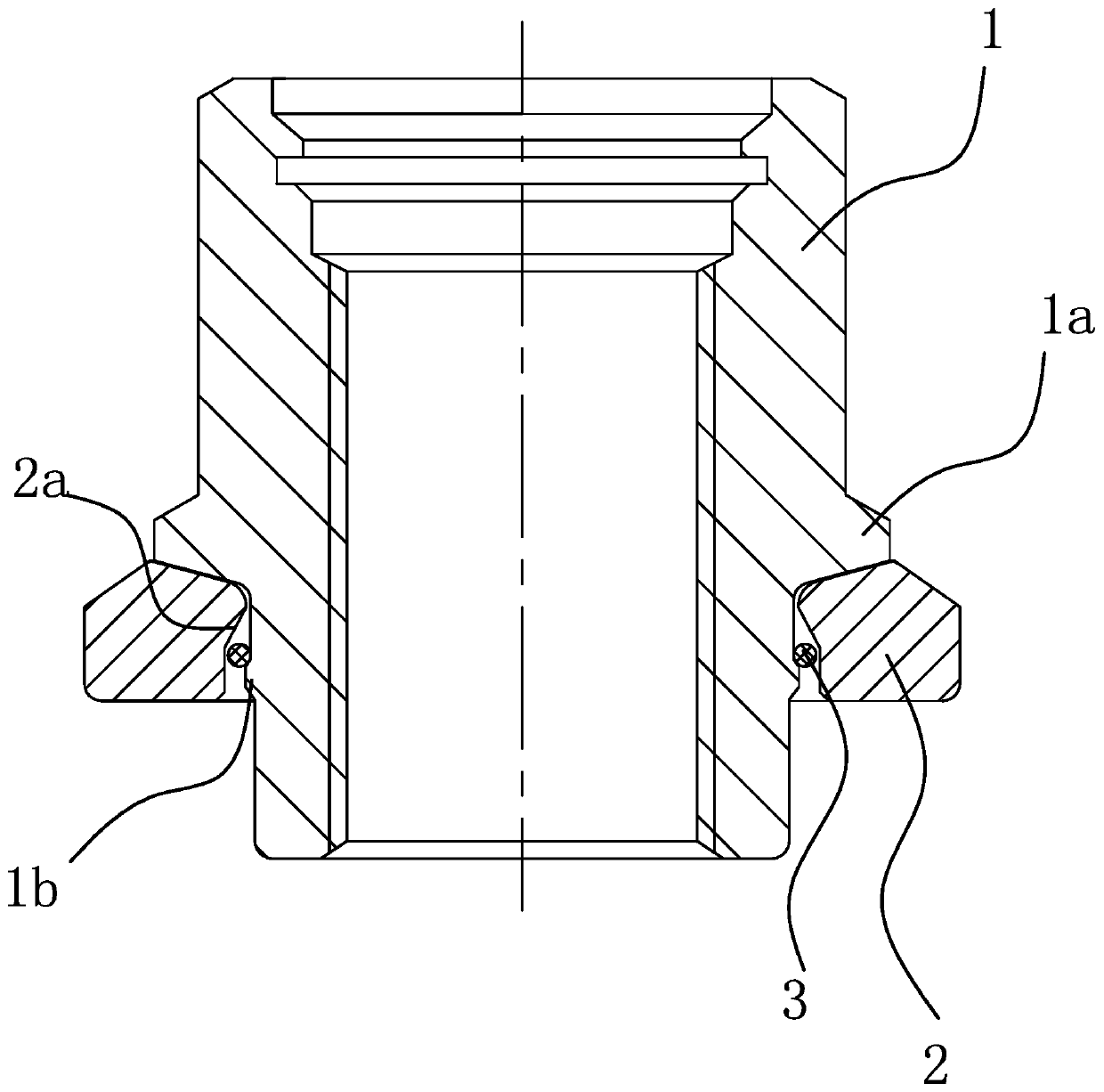

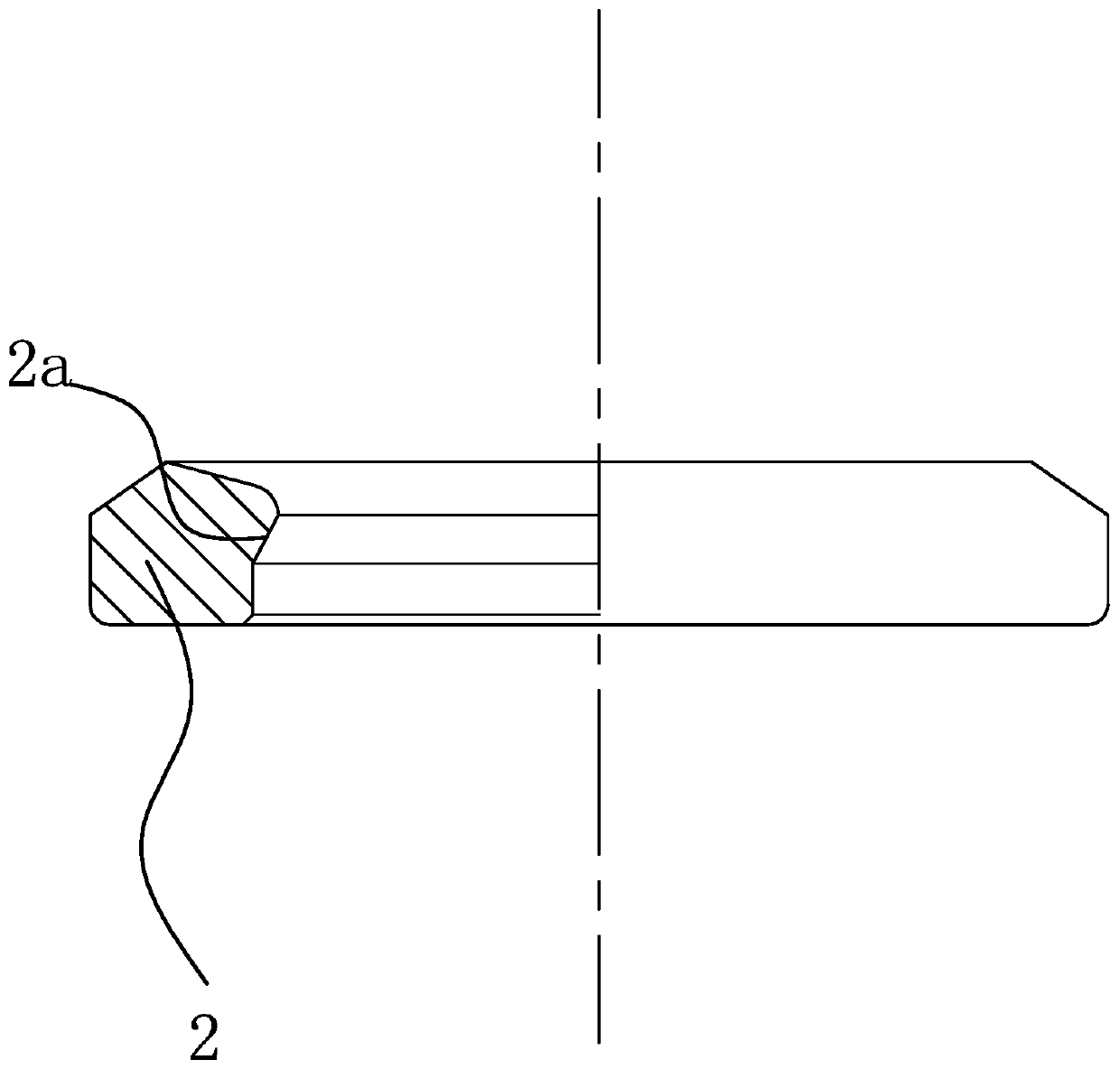

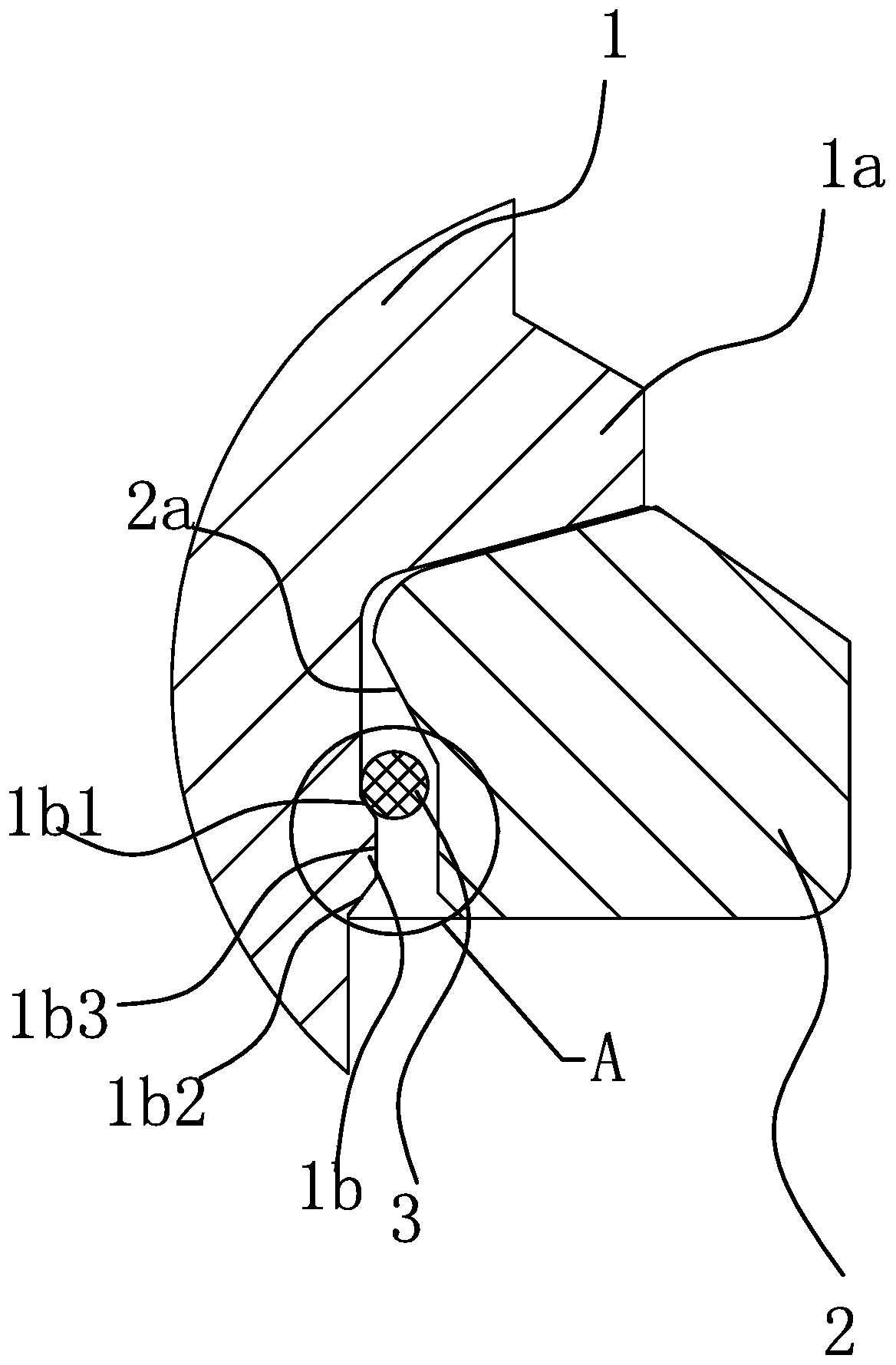

[0045] Such as Figure 1 to Figure 4 , Figure 6As shown, the combined connector includes a nut body 1 and a washer 2. The nut body 1 has a washer retaining edge 1a for blocking the washer 2. The combined connector also includes an elastic ring 3 with a variable inner diameter. The elastic ring 3 is sleeved on the On the nut body 1, the nut body 1 has a limiting portion 1b that restricts the axial movement of the elastic ring 3. The limiting portion 1b can prevent the elastic ring 3 from detaching from the nut body 1. The inner wall of the washer 2 has a flared shape toward the elastic ring 3. The minimum inner diameter of the gasket 2 is smaller than the minimum outer diameter of the elastic ring 3 on the working surface 2a. When the gasket 2 has a tendency to disengage, the working surface 2a can squeeze the elastic ring 3, so that the elastic ring 3 has a tendency to be tightened. It is artificially stipulated that one end on which the elastic ring 3 is installed on the nu...

Embodiment 2

[0049] Such as Figure 5 and Figure 7 As shown, the difference between this embodiment and the first embodiment is that the limiting part 1b is annular and has a flaring-shaped acting surface 1b1 on the top, the elastic ring 3 is placed on the acting surface 1b1, and the acting surface 1 2a It is opposite to the flaring direction of the acting surface 1b1. The action surface 1b1 is set as a constricted shape opposite to the flared shape, and a recessed accommodation groove 1b1a is formed between the reverse necked-shaped action surface 2 1b1 and the nut body 1, and a part of the elastic ring 3 is located in the accommodation groove 1b1a, When the active surface 1b1 squeezes the elastic ring 3, the accommodation groove 1b1a has a limiting effect on the elastic ring 3, and can play a role in preventing the elastic ring 3 from detaching. Adaptive changes will not be repeated here, and are common knowledge of those skilled in the art.

[0050] The detailed structures, material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com