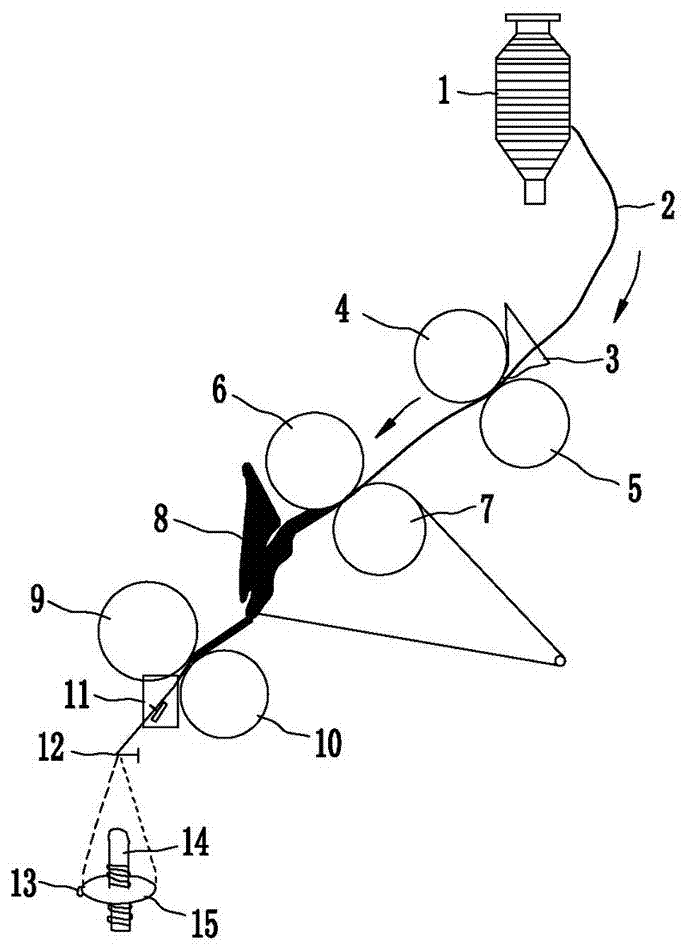

Chinese Patent Publication No. CN103757762A, published on April 30, 2014, the name of the invention is a spinning method for fiberizing strands, the patent discloses a spinning method for fiberizing strands, the method On the basis of the ring spinning technology, a device for fiberizing the sliver is installed in the drafting area of the spun yarn, which increases the control of the fibers in the drafting area, and can control the fibers of the sliver with the number of fibers gradually decreasing. For the

smoothing effect, the front end of the device is very close to the meshing line between the front top roller and the front roller, which can significantly reduce yarn hairiness, improve yarn evenness and

yarn strength, and reduce the edge of the twisting triangle area of spun yarn The fiber is sucked away by the suction tube and becomes

bellows, which is beneficial to improve the yield of spun yarn. However, this method can only control the fiber in the drafting area of the spun yarn, and does not have any management on the fiber

coming out of the front nip, especially the fiber entering the spun yarn. The fibers in the spinning triangle are not constrained, and this method does not have a significant effect on improving the ring-spun yarn

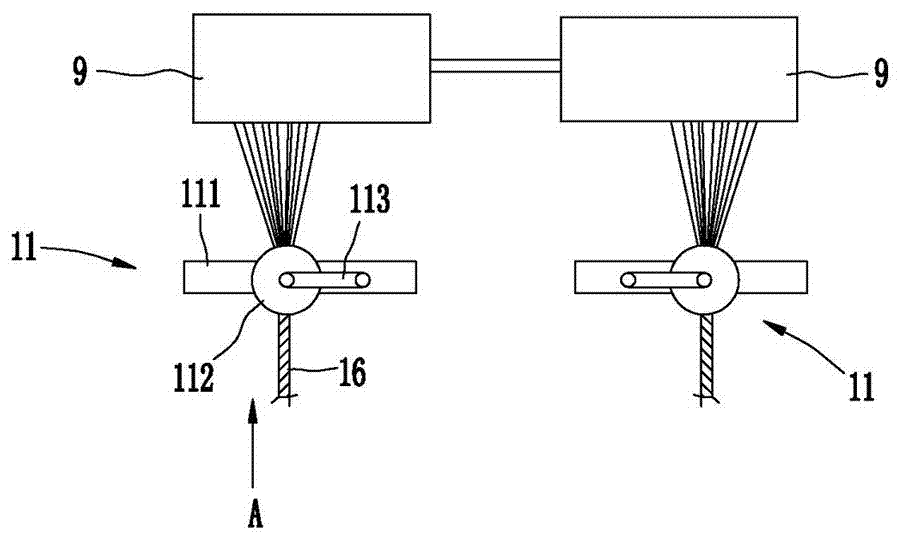

Chinese Patent Publication No. CN104357972A, published on February 18, 2015, the name of the invention is a spinning method for double aggregation of strand fibers, and a spinning method for double aggregation of strand fibers is proposed. A pre-accumulating device is installed in the front drafting area of the spinning frame, and the strands are fed into the pre-accumulating device through the holding jaw composed of the upper

rubber ring and the lower apron. After the output of the front nip composed of the front roller, after the accumulation treatment of the heavy accumulation device, the yarn guide hook, the steel ring and the traveler are wound on the spun yarn

bobbin, and the heavy accumulation area is surrounded by the heavy accumulation area due to the lifting of the yarn guide hook The arc is constantly changing, the length of the arc surrounded by re-agglomeration is too short, and the effect of re-agglomeration is unstable

Chinese Patent Publication No. CN104357973A, published on February 18, 2015, the name of the invention is a re-concentration spinning method for adjusting

yarn tension balance, and a re-concentration spinning method for adjusting

yarn tension balance is proposed. A pre-accumulating device is installed in the front drafting area of the ring spinning

machine, and the strands are fed into the pre-accumulating device through the gripping jaws composed of the upper

rubber ring and the lower apron, and the strands pre-accumulated by the pre-accumulating device After being output from the front nip composed of the front top roller and the front roller, the yarn passes through the re-accumulation device, the tension balance device, and then through the yarn guide hook, the steel ring, and the traveler, and is wound on the spun yarn

bobbin. This method solves the problem of The lifting of the yarn guide hook causes the spinning tension in the re-accumulation area to change continuously, the length of the re-accumulation surrounding arc is short, and the re-accumulation effect is unstable. transmission, thereby affecting yarn

dryness and strength

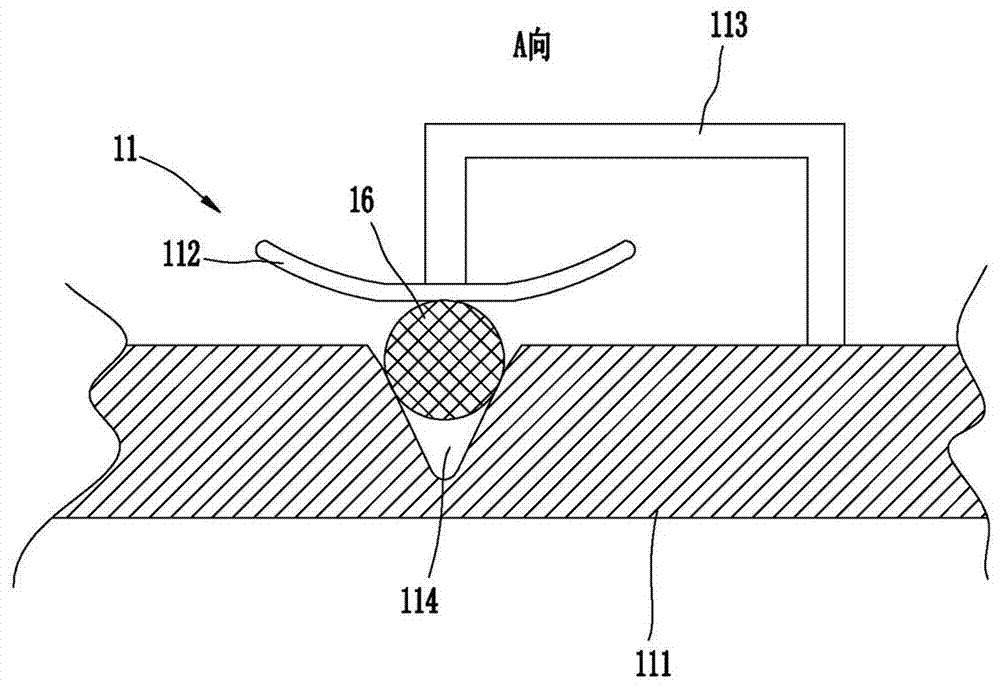

Chinese Patent Publication No. CN104451981A, published on March 25, 2015, the name of the invention is a re-concentration spinning method with improved re-concentration spinning enclosing

arc length, and a method with improved re-concentration spinning enclosing

arc length is proposed The re-concentration spinning method, the invention adopts a pre-concentration device installed in the front drafting area of the ring spinning frame. After the pre-accumulated strands are output from the front nip composed of the front top roller and the front roller, the strands are re-assembled by the re-accumulation processor, and then processed by the re-accumulator with increased encircling

arc length, and then led to The yarn hook, steel ring, and traveler are wound on the spun yarn tube. This method solves the problem that the re-accumulation surrounding arc in the re-accumulation area is constantly changing due to the lifting of the yarn guide hook, the length of the re-accumulation surrounding arc is short, and the re-accumulation effect is unstable. problem, but the ensuing problem is that the

processing device of the heavy

concentrator with the increase of the surrounding arc length has a twist trap, which prevents the transmission of the twist and affects the dryness and strength of the yarn.

The spinning method is cumbersome to operate, and the joint needs to lift the accumulating wheel, and in large-scale applications, the accumulating wheel is easy to accumulate flowers, resulting in unsmooth rotation and end breakage

Login to View More

Login to View More