Torpedo hanging mechanism

A hanging and torpedo technology, which is applied to torpedo launchers, offensive equipment, weapon types, etc., can solve the problems of unfavorable load-carrying torpedo stability, etc., and achieve the effect of simple structure, small structure and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

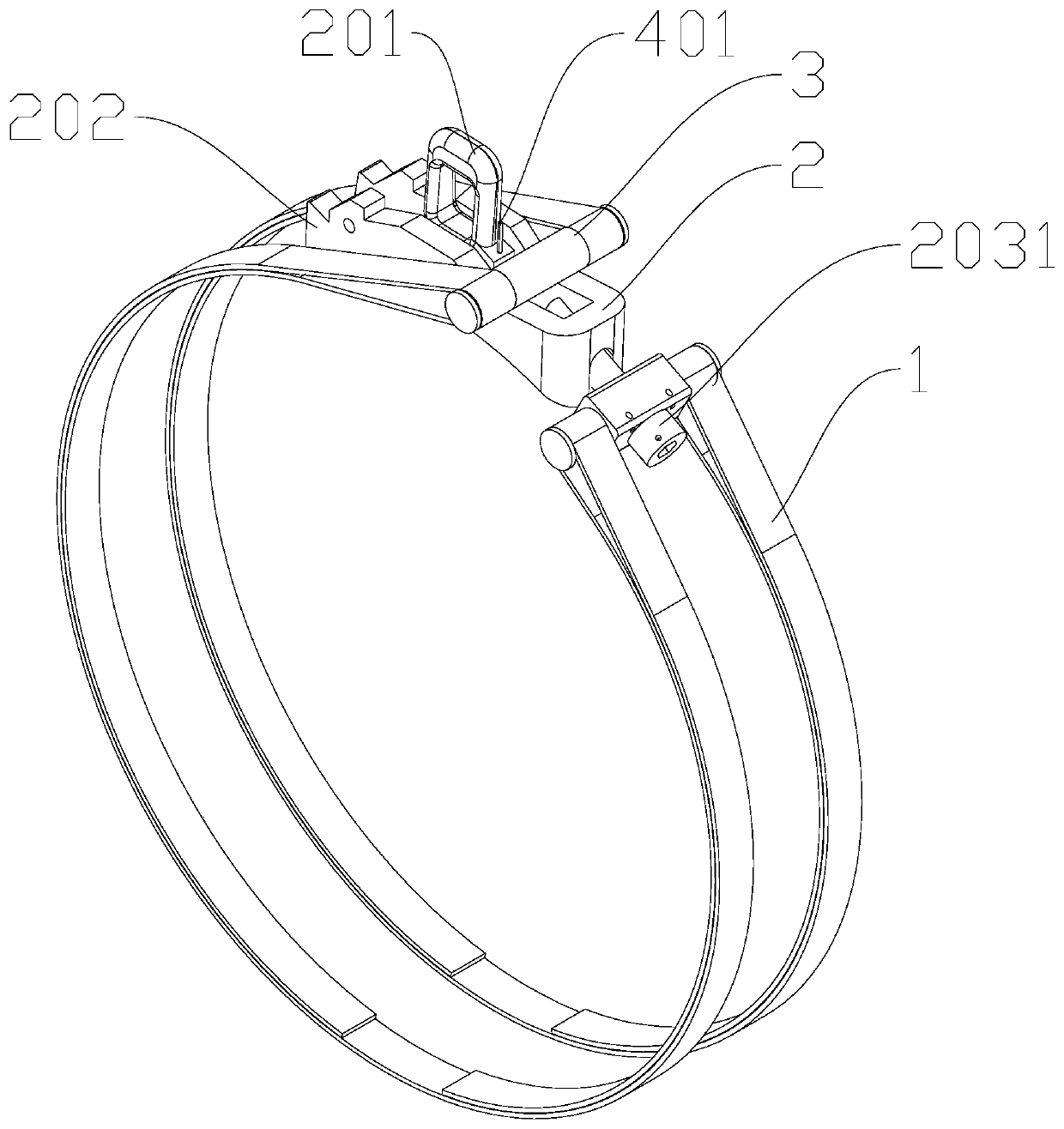

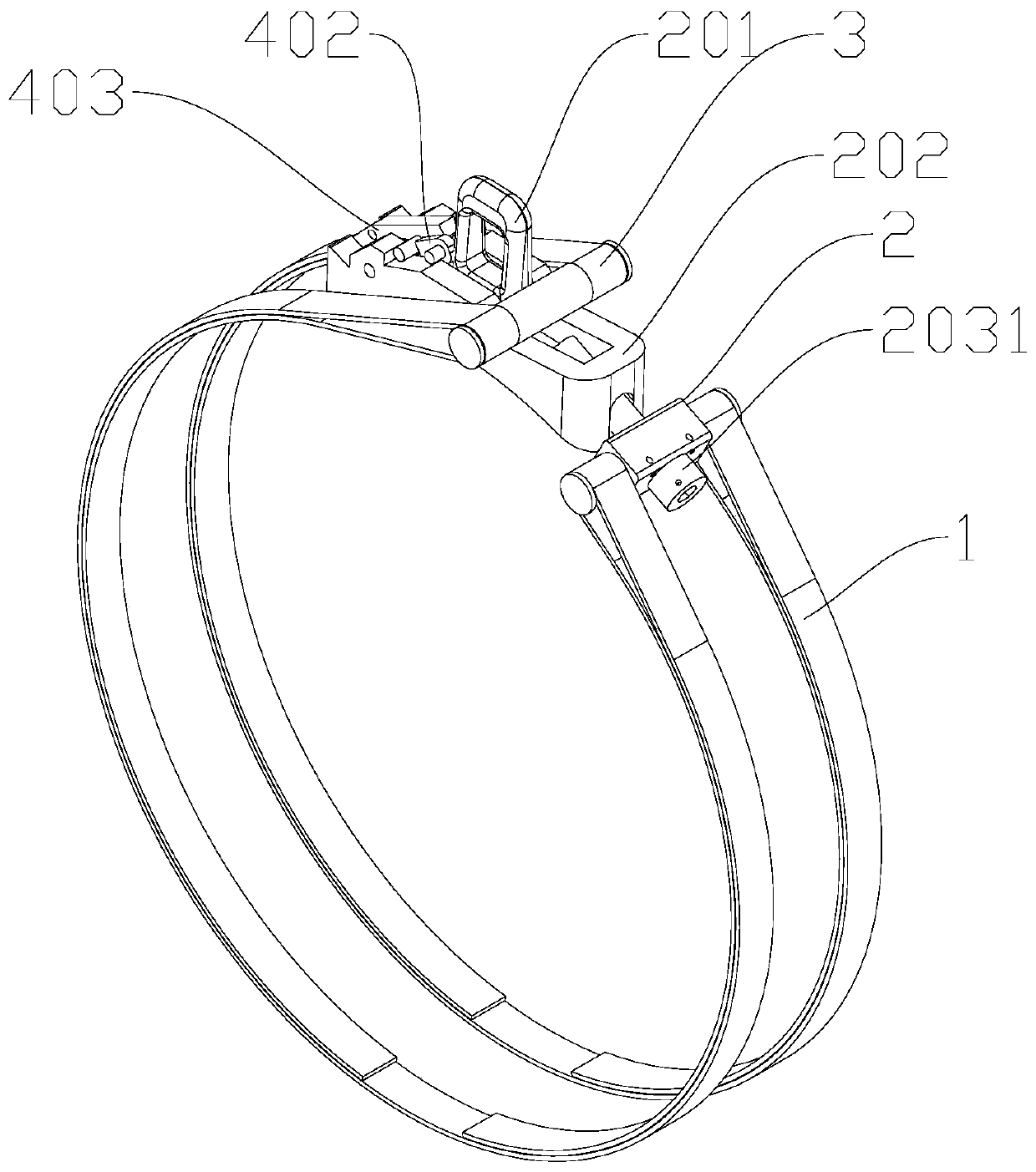

[0029] see Figure 1~5 , a torpedo hanging mechanism, comprising an annular hoop, the annular hoop includes a first joint and a second joint, the first joint is hingedly provided with lifting lugs, and the first joint is provided with a ring for limiting the vertical direction of the lifting ears. And the limit mechanism can be pulled out from the first joint part, and the second joint part can be hung on the lifting lug.

[0030] In this embodiment, the ring-shaped hoop is passed around the torpedo body so that the second joint part is sleeved on the lifting lug, and the limit mechanism is used to limit the vertical position of the lifting lug on the first joint part. Use the grabbing mechanism of the ship to hang the lifting lug and lift it up, so as to realize the lifting of the torpedo, and then connect the limit mechanism with a vertical steel wire on the ship. The structure is simple and easy to operate. When the torpedo is released, the grabbing mechanism on the ship r...

Embodiment 2

[0032] see Figure 1~5 , a torpedo hanging mechanism, comprising an annular hoop, the annular hoop includes a first joint and a second joint, the first joint is hingedly provided with lifting lugs, and the first joint is provided with a ring for limiting the vertical direction of the lifting ears. And the limit mechanism can be pulled out from the first joint part, and the second joint part can be hung on the lifting lug.

[0033] The hoop strap is elastic. The ring band can rely on its own elastic force, which is beneficial for torpedoes with different pipe diameters and sizes, and locks the torpedo tightly.

[0034] Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0036] see Figure 1~5 , a torpedo hanging mechanism, comprising an annular hoop, the annular hoop includes a first joint and a second joint, the first joint is hingedly provided with lifting lugs, and the first joint is provided with a ring for limiting the vertical direction of the lifting ears. And the limit mechanism can be pulled out from the first joint part, and the second joint part can be hung on the lifting lug.

[0037] refer to figure 2 , the first joint part includes a lifting lug fixing seat, the lifting lug is hinged on the lifting lug fixing seat, and the lifting lug hinge seat is beneficial to the fixing of the lifting lug.

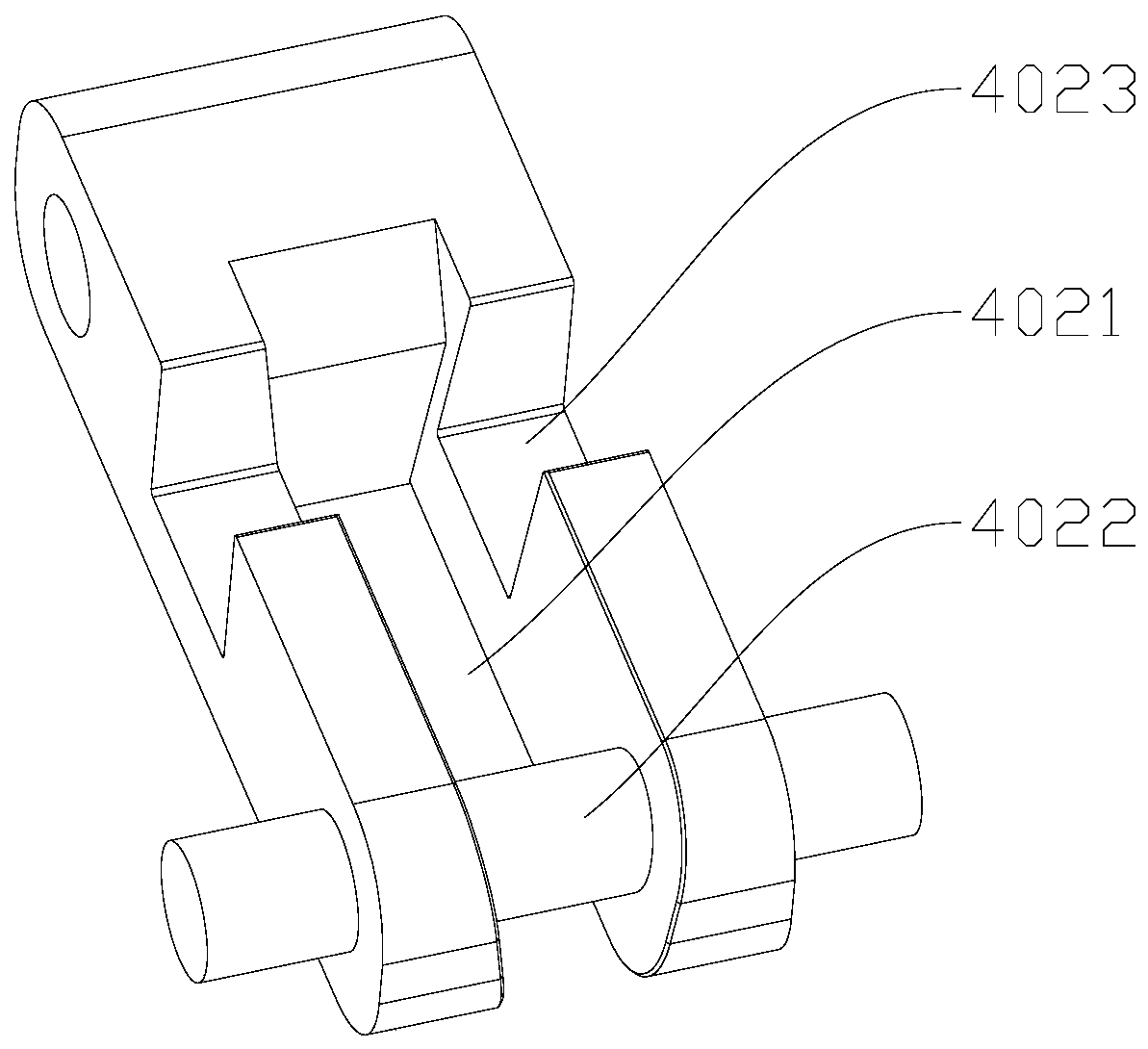

[0038] As a preferred manner, the first joint part also includes a length adjustment mechanism, and the length adjustment mechanism includes a locking bolt connected to the annular strap, and the locking bolt can be screwed into the fixing seat of the lifting lug. The diameter of the torpedo can be covered by adjusting the locking bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com