A kind of weak twist blended yarn and production method thereof

A technology of blended yarn and spun yarn, applied in the direction of yarn, textile and paper making, can solve the problems of no obvious advantage in heat retention, insufficient yarn bulkiness, limited thermal insulation performance, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

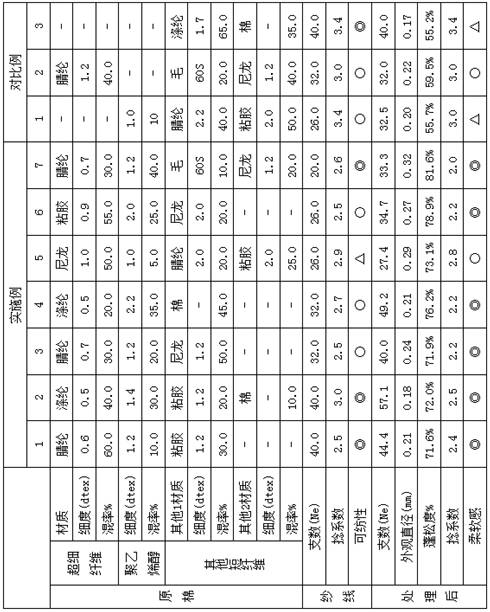

Embodiment 1

[0038] Select the superfine acrylic staple fiber of 60% by weight of 0.6tex, the water-soluble polyvinyl alcohol fiber of 1.2dtex of 10% by weight and the viscose staple fiber of 1.2dtex of 30% by weight for use as raw materials, mix → comb → combine →Roving→spinning→winding process to form a blended yarn, wherein the imperial twist coefficient of the spun yarn in the spinning process is set to 2.5. The polyvinyl alcohol fibers were removed by hot water treatment at 95°C, and then dyed under conventional conditions to obtain blended yarns. The specific performance parameters are shown in Table 1.

Embodiment 2

[0040]40% by weight of 0.5tex superfine polyester staple fiber, 30% by weight of 1.4dtex water-soluble polyvinyl alcohol fiber, 20% by weight of 1.2dtex viscose staple fiber and 10% by weight of cotton staple fiber are used as raw materials , carry out mixing→carding→combining→roving→spinning→winding process to form blended yarn, wherein the imperial twist coefficient of the spun yarn in the spinning process is set to 3.0. The polyvinyl alcohol fibers were removed by hot water treatment at 95°C, and then dyed under conventional conditions to obtain blended yarns. The specific performance parameters are shown in Table 1.

Embodiment 3

[0042] Use 30% by weight of 0.7tex superfine acrylic staple fiber, 20% by weight of 1.2dtex water-soluble polyvinyl alcohol fiber and 50% by weight of 1.2dtex nylon staple fiber as raw materials, mix → carding → merge → Roving→spinning→winding process forms a blended yarn, wherein the imperial twist coefficient of the spun yarn in the spinning process is set to 2.5. The polyvinyl alcohol fibers were removed by hot water treatment at 95°C, and then dyed under conventional conditions to obtain blended yarns. The specific performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com