Mounting and fixing structure for super-high-rise pumping pipeline

A pipeline installation and super high-rise technology, applied in the direction of pipeline supports, building structures, siphons, etc., can solve the problems that affect the normal use of elbows, poor support effect of vertical pipes, and inability to bend pipes to support, etc., to ensure the effect of supporting positioning , Use safe and reliable, ensure the effect of supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

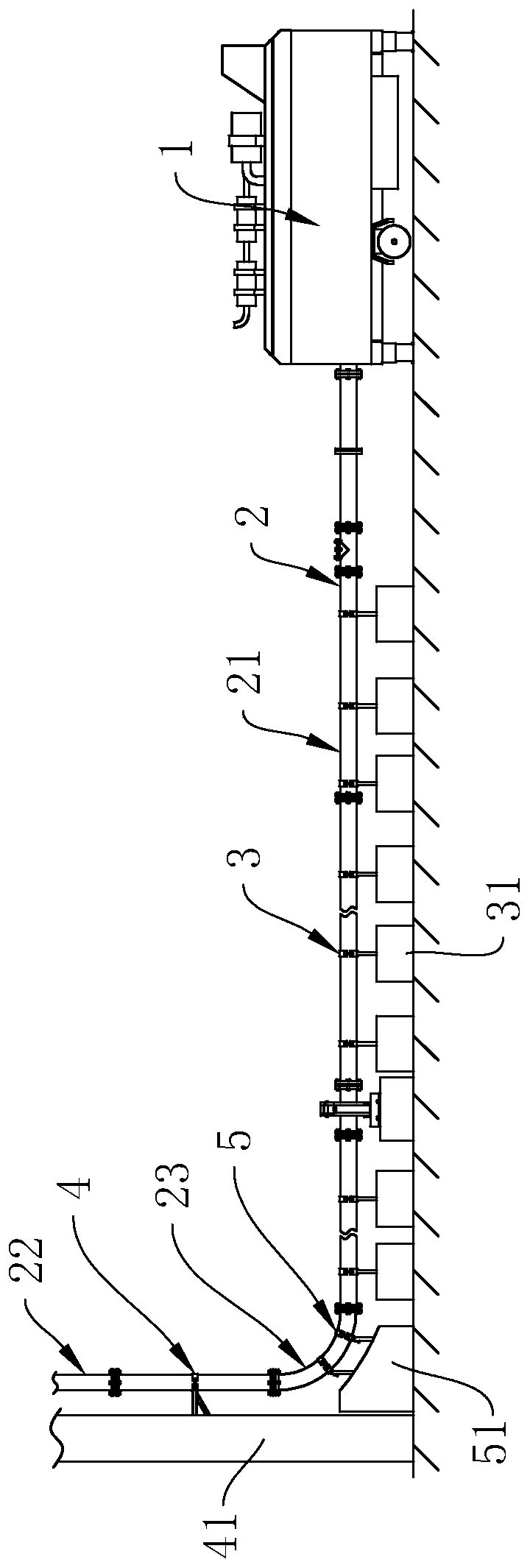

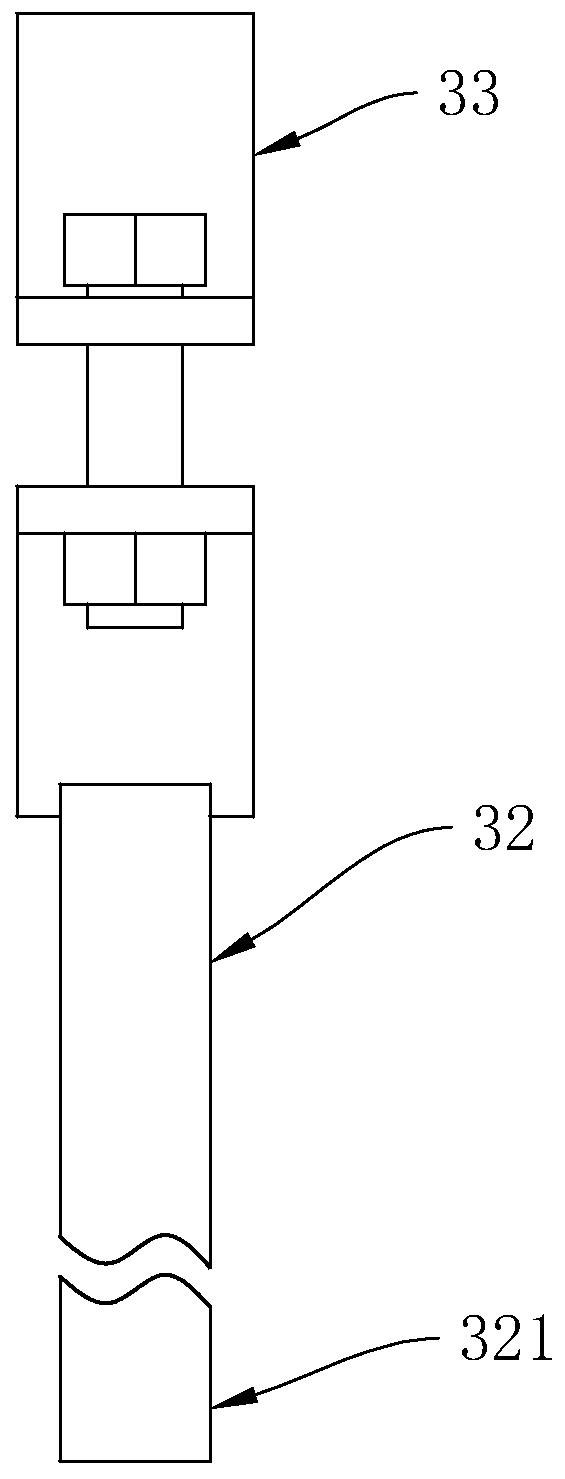

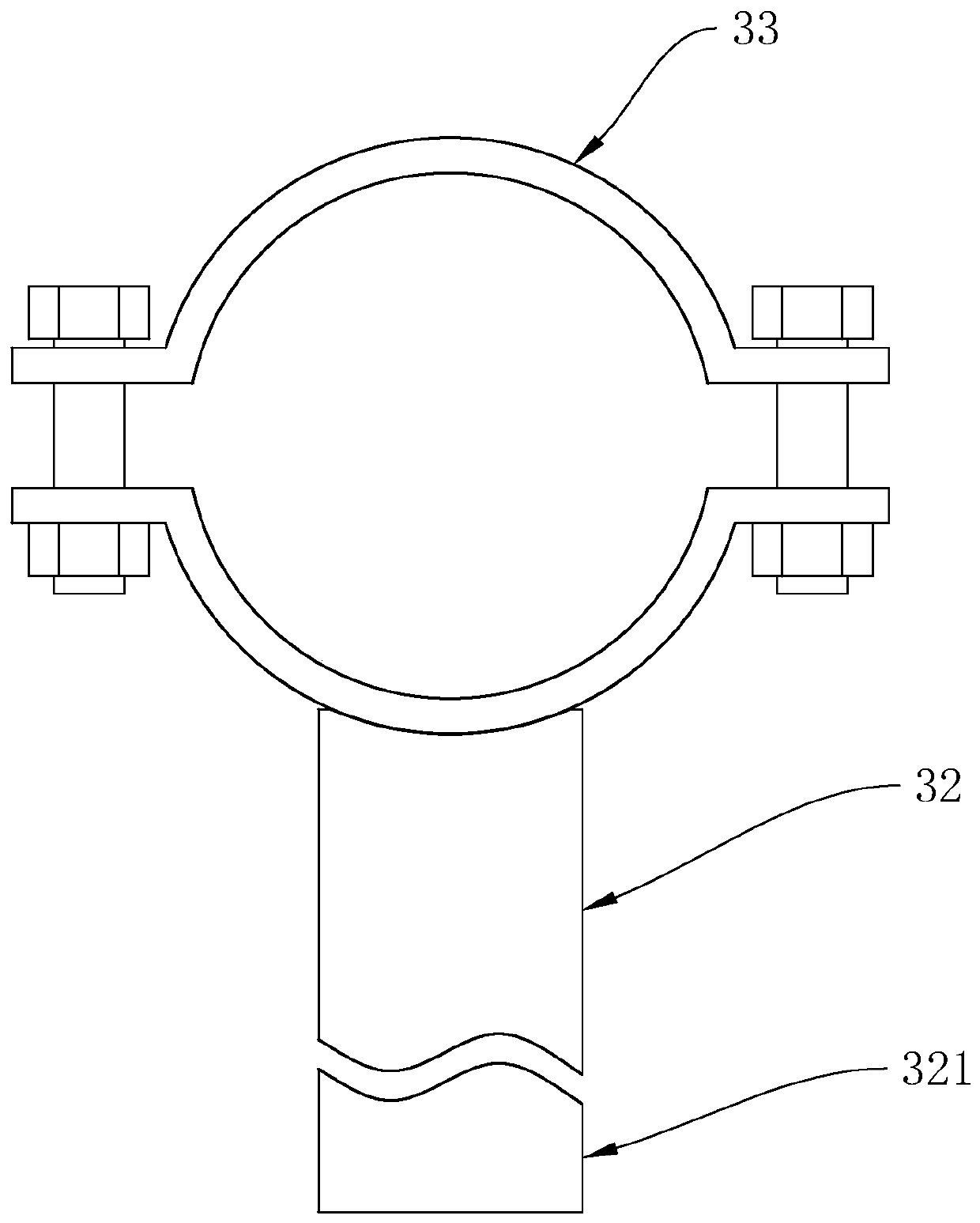

[0049] refer to figure 1 , the present invention discloses a super-high-rise pumping pipeline installation and fixing structure, including a pump pipe 2 for connecting with a concrete pump 1, the pump pipe 2 includes a horizontal pipe 21, a vertical pipe 22, and a pipe connected to the horizontal pipe 21 and the vertical pipe. The elbow 23 between the pipes 22, the concrete pump 1 in this embodiment adopts the HBT110.26.390RS drag pump; the pump pipe 2 is equipped with at least one hydraulic shut-off valve, and the pump pipe in this embodiment is equipped with two hydraulic shut-off valves , one of the hydraulic shut-off valves is installed on the horizontal pipe 21 to facilitate the recovery of waste water residue from pipe cleaning, and the other hydraulic shut-off valve is installed at the starting point of the vertical pipe 22 to avoid the concrete backfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com