High-speed strong impact testing machine

An impact testing machine, high-speed technology, used in impact testing, machine/structural component testing, measuring devices, etc., can solve the problems of small response peak value, small equipment quality, and military equipment testing cannot meet the requirements, and achieve large impact load, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

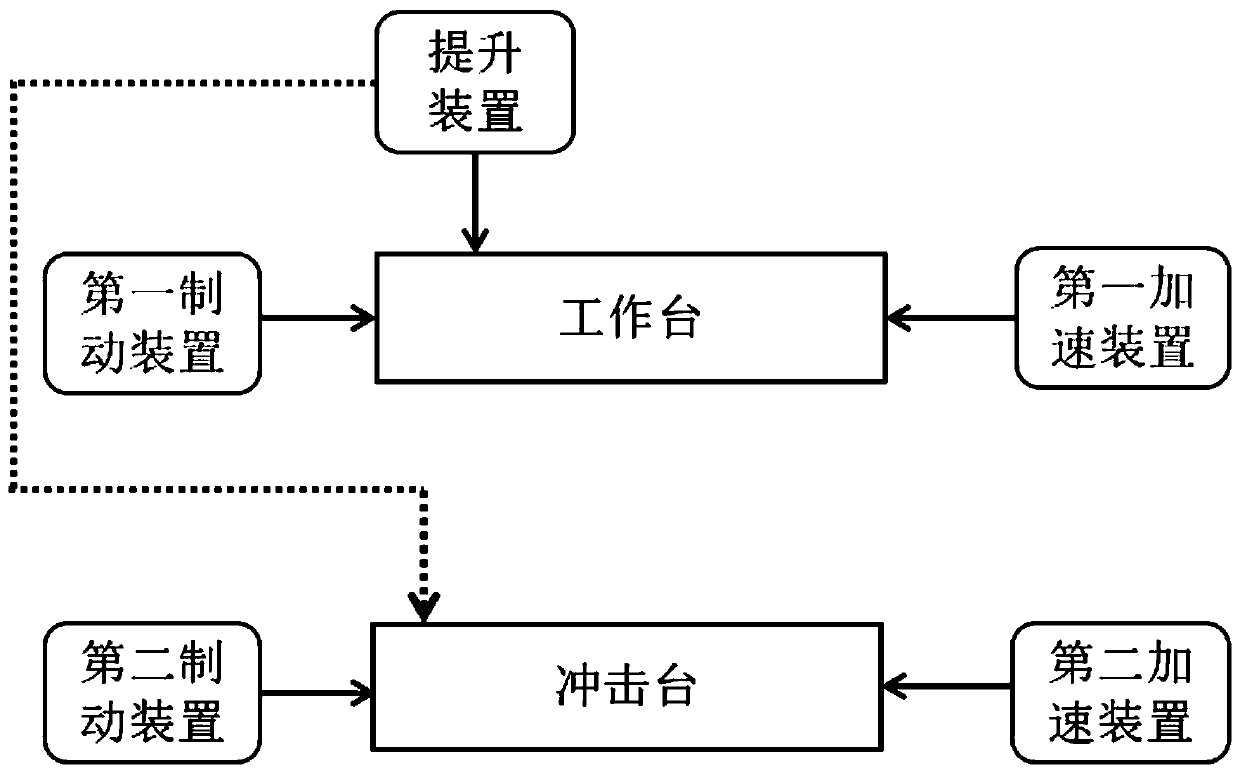

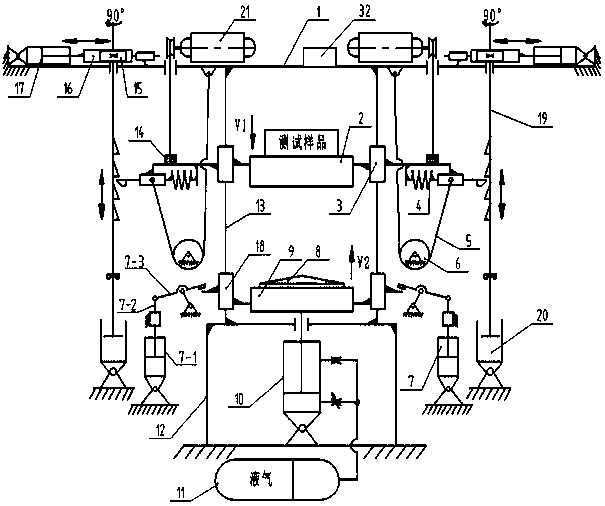

[0045] Such as figure 1 with 2 Shown, a kind of high-speed strong impact testing machine comprises workbench 2, impact table 9, hoisting device, frame 12 and top plate 1, and it also comprises first accelerating device and second accelerating device; Between frame 12 and top plate 1 The space is connected by a guide column 13, which is also connected with a worktable 2 and an impact table 9. One end of the lifting device is arranged on the top plate 1, and the other end of the lifting device can be connected or separated from the worktable 2. The first acceleration device One end of the first acceleration device is arranged on the top plate 1, the other end of the first acceleration device can be connected or contacted or separated from the workbench 2, one end of the second acceleration device is arranged on the frame 12, and the other end of the second acceleration device can be connected to the impact table 9 contact or separation.

[0046] The first acceleration device p...

Embodiment 2

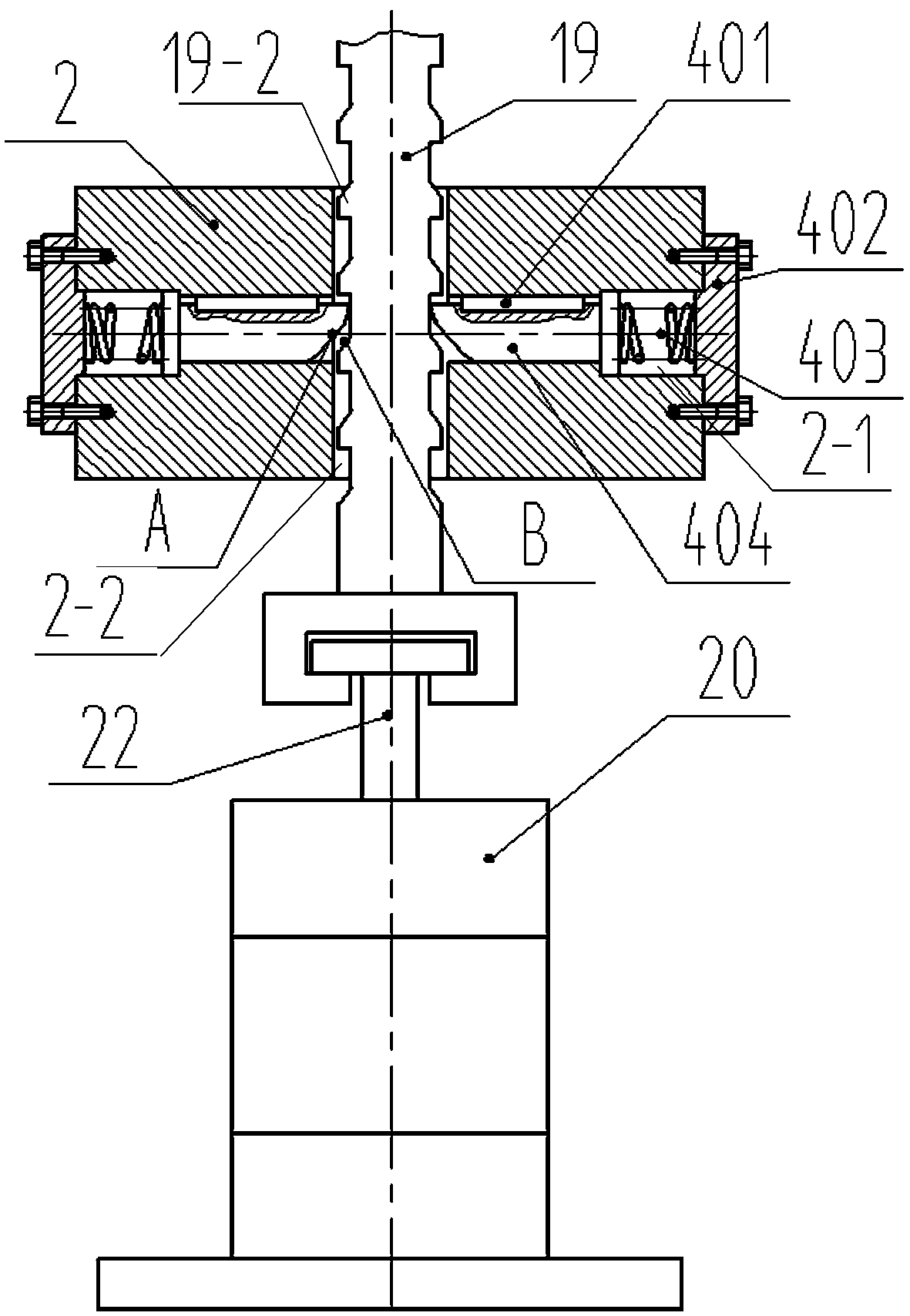

[0068] Such as figure 1 and Figure 5 Shown, a kind of high-speed strong impact testing machine comprises workbench 2, impact table 9, hoisting device, frame 12 and top plate 1, and it also comprises first accelerating device and second accelerating device; Between frame 12 and top plate 1 The space is connected by a guide column 13, which is also connected with a worktable 2 and an impact table 9. One end of the lifting device is arranged on the top plate 1, and the other end of the lifting device can be connected or separated from the worktable 2. The first acceleration device One end of the first acceleration device is arranged on the top plate 1, the other end of the first acceleration device can be connected or contacted or separated from the workbench 2, one end of the second acceleration device is arranged on the frame 12, and the other end of the second acceleration device can be connected to the impact table 9 contact or separation.

[0069] The first acceleration d...

Embodiment 3

[0088] Such as figure 1 and Figure 6 Shown, a kind of high-speed strong impact testing machine comprises workbench 2, impact table 9, hoisting device, frame 12 and top plate 1, and it also comprises first accelerating device and second accelerating device; Between frame 12 and top plate 1 The space is connected by a guide column 13, which is also connected with a worktable 2 and an impact table 9. One end of the lifting device is arranged on the top plate 1, and the other end of the lifting device can be connected or separated from the worktable 2. The first acceleration device One end of the first acceleration device is arranged on the top plate 1, the other end of the first acceleration device can be connected or contacted or separated from the workbench 2, one end of the second acceleration device is arranged on the frame 12, and the other end of the second acceleration device can be connected to the impact table 9 contact or separation.

[0089] The first acceleration d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com