Vertical high-speed impact testing machine capable of generating negative waves

A high-speed impact and testing machine technology, applied in the direction of impact testing, machine/structural component testing, measuring devices, etc., to achieve the effects of improving reliability, saving time, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to simulate the real environment, my country urgently needs to develop a strong impact testing machine with large load, low cost, high acceleration and negative waves in the laboratory environment to meet the impact test requirements of civil and military equipment.

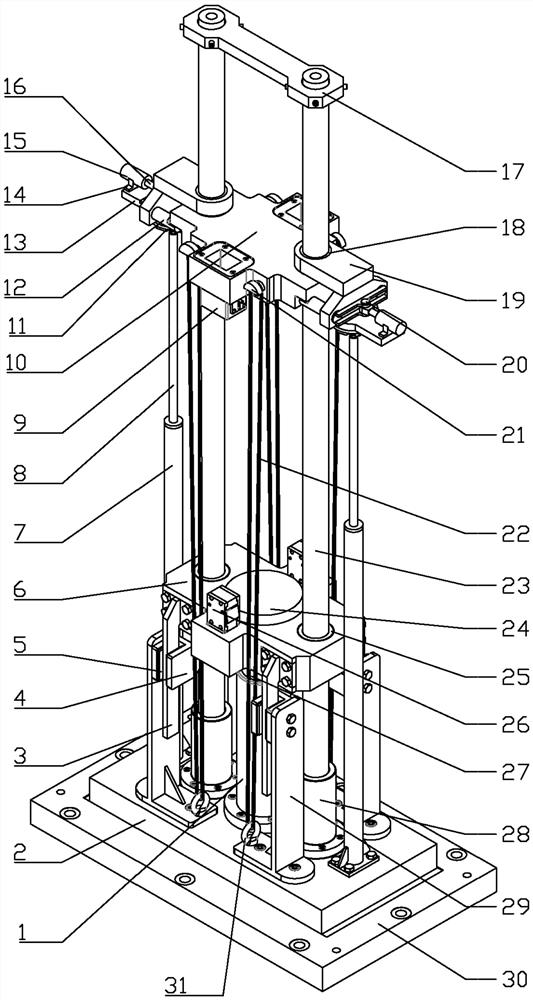

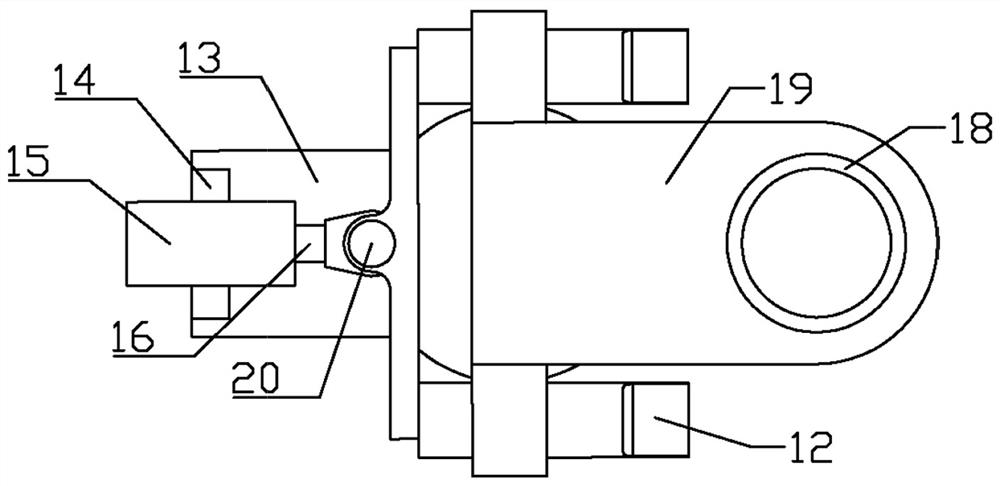

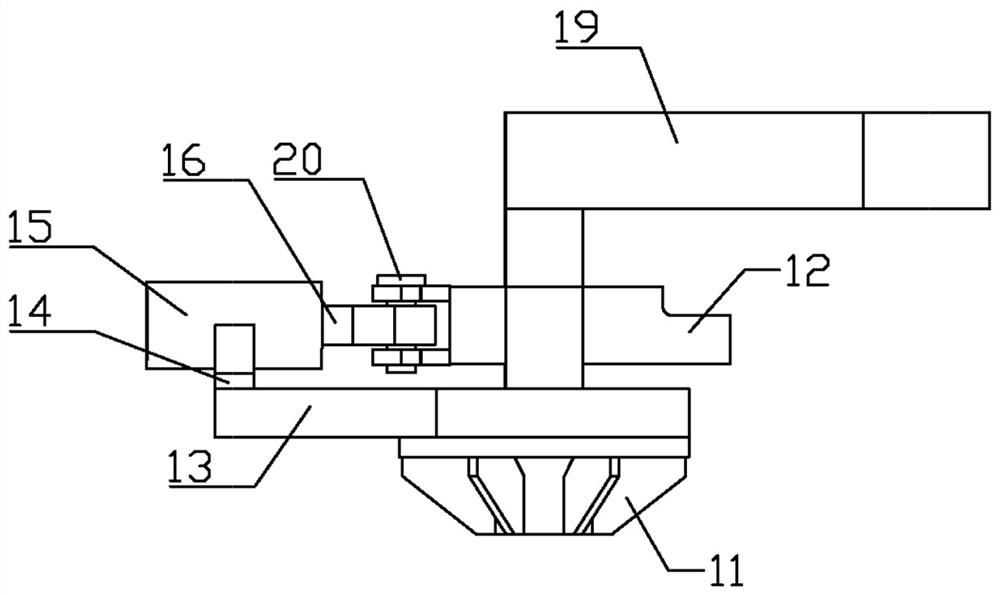

[0043] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The present invention proposes a new way of negative wave generation, that is, the test bench and the shock bench are connected together by an interlock mechanism and braked at the same time, and the connection method can also be replaced by other feasible mechanism connection methods. It can be understood that the described embodiments are part of the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com