A kind of thruster composite material conduit and preparation method thereof

A composite material and thruster technology, which is applied in ship propulsion, propulsion components, ship construction, etc., can solve the problems of heavy propeller duct weight, poor seawater corrosion resistance, etc., and achieve weight reduction and production cost, high seawater corrosion resistance , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

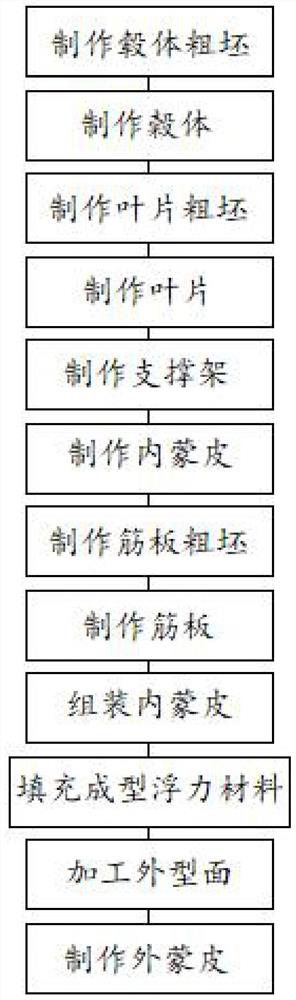

Method used

Image

Examples

Embodiment 1

[0050] The autoclave process refers to the process of laying up the single-layer prepreg in a predetermined direction to form a composite material blank, placing it in an autoclave, and completing the curing process under a certain temperature and pressure. An autoclave is a special pressure vessel that can withstand and regulate a set temperature and pressure range. The blank is laid on the surface of the mold with a release agent, and then covered with a porous anti-adhesive cloth (membrane), suction felt and air felt, sealed in a vacuum bag, and then put into an autoclave. Before heating and curing, vacuumize the bag to remove air and volatiles, and then heat up, pressurize and cure according to the curing system of different resins.

[0051] The formulation and implementation of curing system is the key to ensure the quality of autoclave molded parts. After heating to a certain temperature, pressurize the billet. The pressure should be to ensure the compaction of the work...

Embodiment 2

[0080] Such as Figure 8 and Figure 9 As shown, on the basis of embodiment 1, this embodiment provides a propeller composite material conduit, which is made by the method described in embodiment 1.

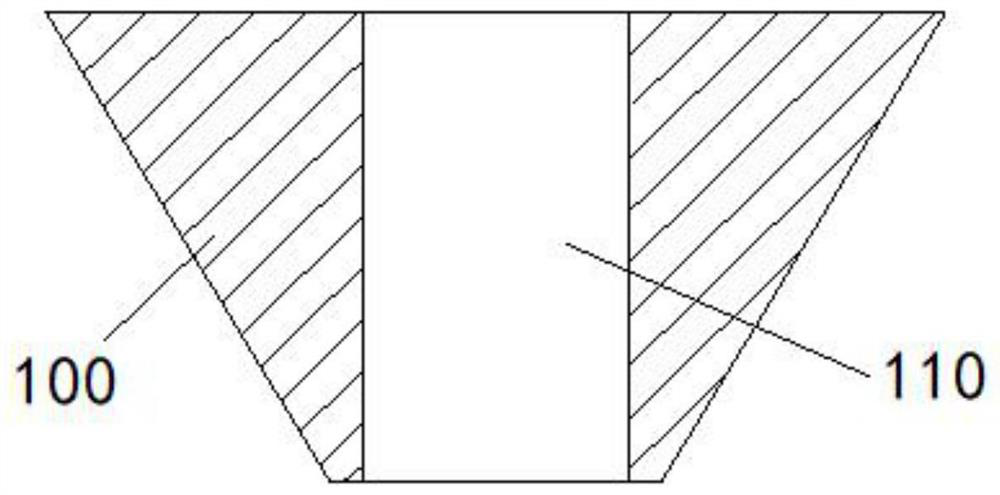

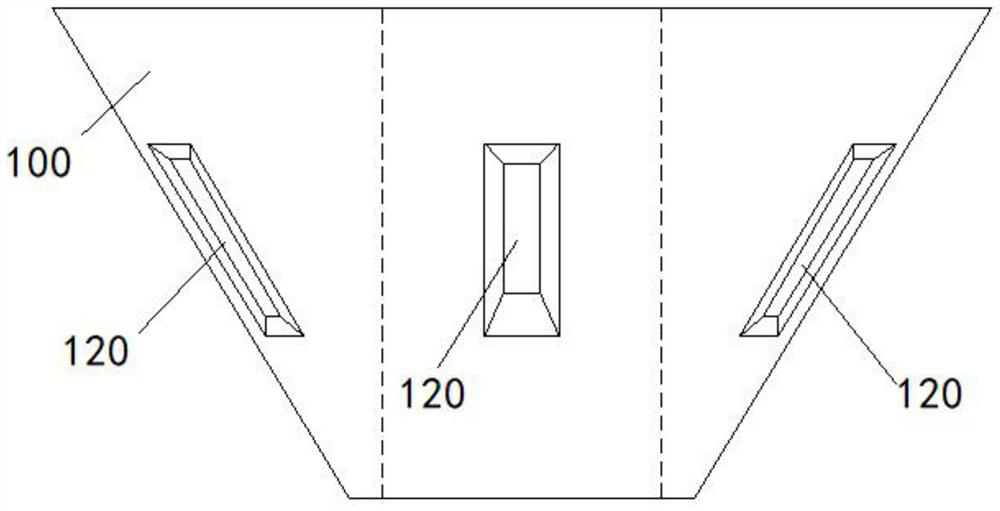

[0081] Preferably, as Figure 8 with Figure 9 As shown, in one of the preferred technical solutions of the present application, the structure of the propeller composite conduit includes: a support frame 7 and a skin 8; the shape of the skin 8 is ring-shaped; the support frame includes: a hub body 1 and the blade 2; the two ends of the blade 2 are fixedly connected to the outer wall of the hub body 1 and the inner wall of the skin 8 respectively.

[0082] Preferably, as Figure 8 with Figure 9 As shown, in one of the preferred technical solutions of the present application, the skin 8 includes an outer skin 6 and an inner skin 3; ribs 4 are arranged inside the skin; one end of the blade 2 and the ribs 4 fixed connection.

[0083] Preferably, in one of the preferred techni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com