Waterproof fabric detection device before fabric determination in garment factory

A technology of waterproof fabrics and detection devices, which is applied in the directions of measuring devices, analysis materials, permeability/surface area analysis, etc., can solve problems such as difficult to grasp flexibly, failure to achieve detection results, troublesome operation, etc., and achieve intuitive detection methods and detection flexibility Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

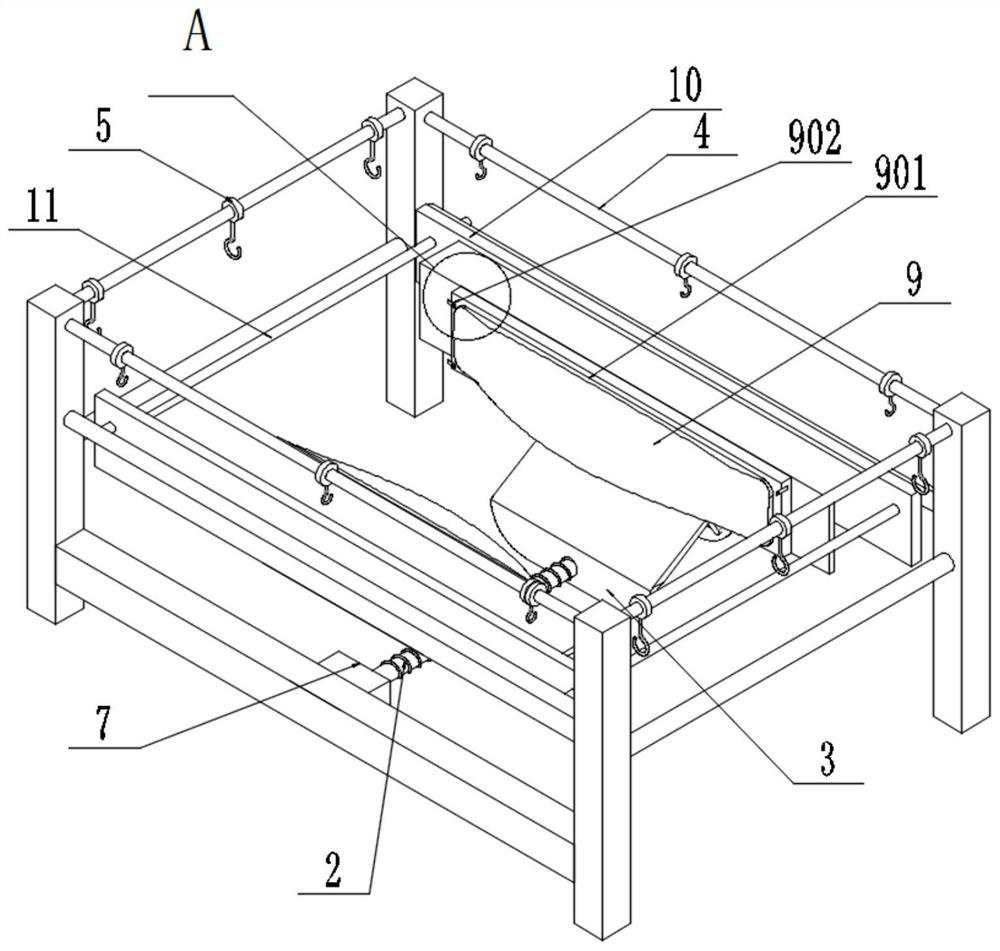

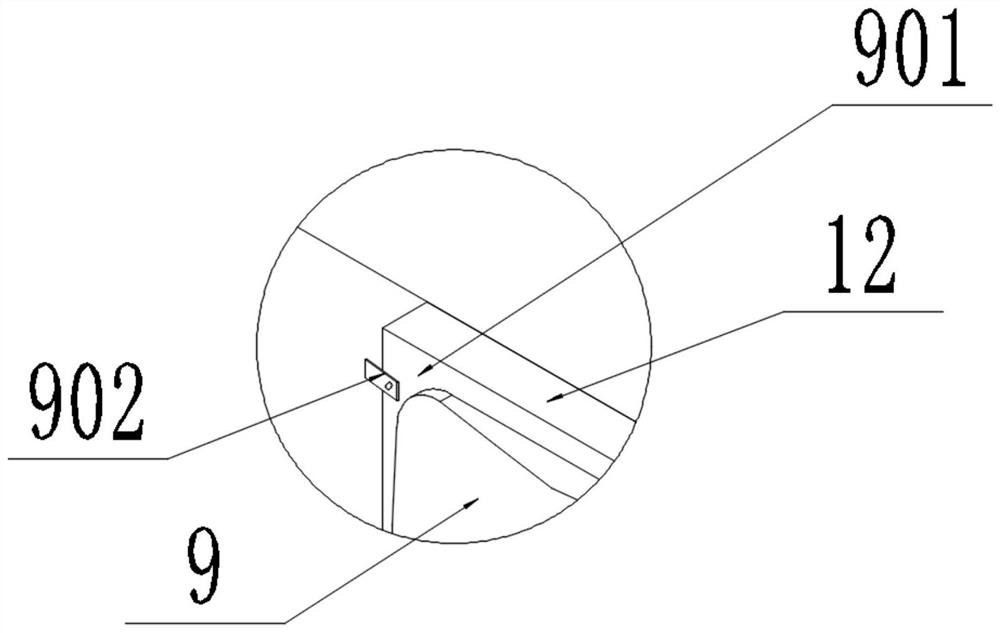

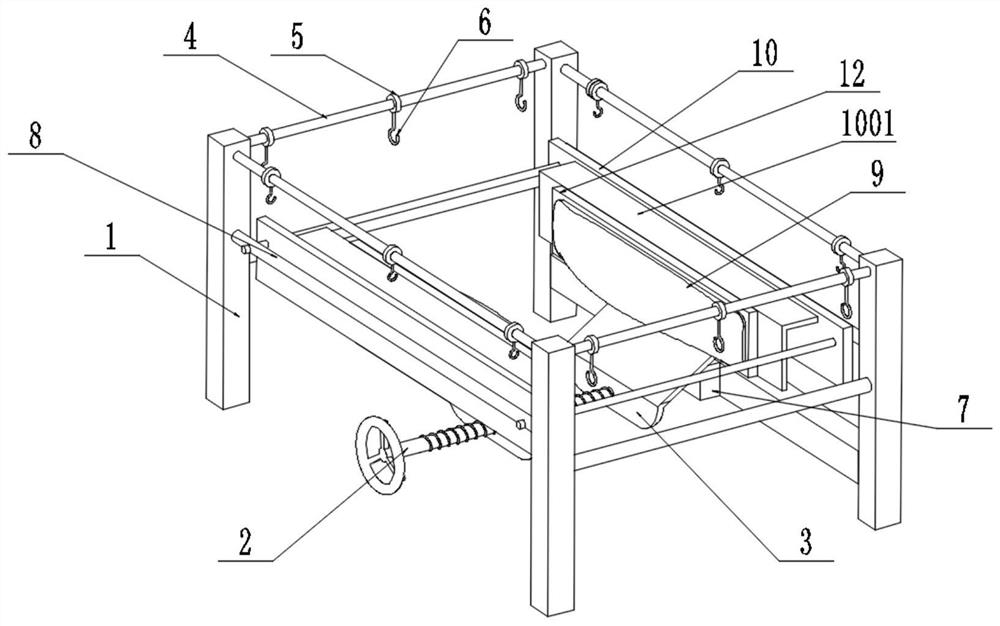

[0026] see Figure 1 to Figure 8 , a kind of embodiment that the present invention provides: the waterproof fabric detection device before cloth of clothing factory is confirmed, comprises frame body 1, bearing seat 7; There are front, rear, left and right four suspenders 4 welded, and three welding sleeves 5 are installed and welded on these suspenders 4; the bottom ends of the welding sleeves 5 are welded with a suspension hook 6 downwards, And these hooks 6 are at the same height position; the bearing seat 7 is installed on the welding connecting plate between the two columns on the rear side of the bottom end of the frame body 1, and a handwheel type screw rod 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com