High-efficiency spherical fuel element on-line real-time imaging detection device

A spherical fuel element and real-time imaging technology, applied in sorting and other directions, can solve problems such as failure to meet production requirements and low detection efficiency, and achieve the effect of improving detection production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

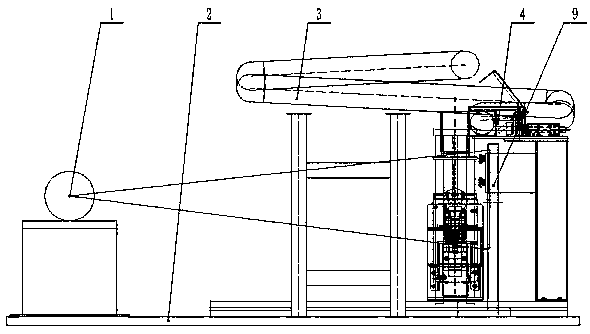

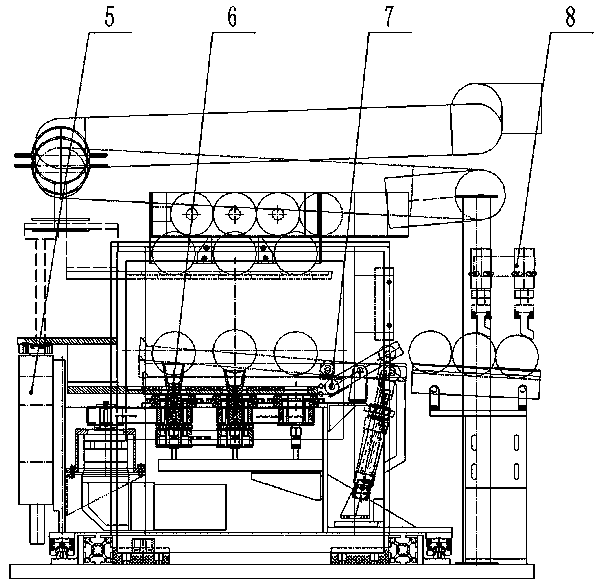

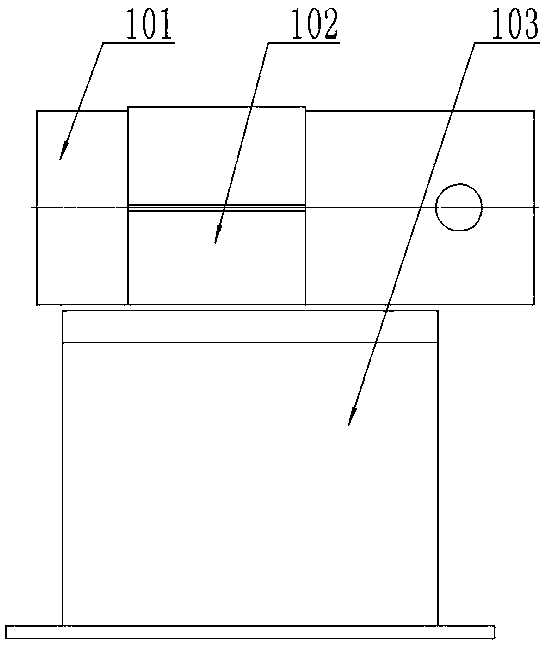

[0030] Such as Figure 1-Figure 10A high-efficiency spherical fuel element online real-time imaging detection device is shown, which is characterized in that it includes: a ray machine and a fixed seat 1, a substrate 2, a ball storage mechanism 3, a material distribution mechanism 4, a material receiving mechanism 5, a rotation mechanism 6, Material shifting mechanism 7, sorting mechanism 8, imaging plate 9, wherein ball storing mechanism 3, rotating mechanism 6 and sorting mechanism 8 are installed on the base plate 2, and base plate 2 is placed on the ground, and the feeding port 304 of ball storing mechanism 3 It is docked with the feeding outer channel, the material outlet is docked with the material distribution mechanism 4, the material receiving mechanism 5, the material shifting mechanism 7 and the imaging plate 9 are fixed on the rotating mechanism 6, and the sorting mechanism 8 is docked with the material discharging outer channel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com