Small material vertical conveyor for building construction

A technology of building construction and conveyors, which is applied in the processing of building materials, construction, building construction, etc., and can solve problems such as difficult picking of materials and slow transportation speed of hoisting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

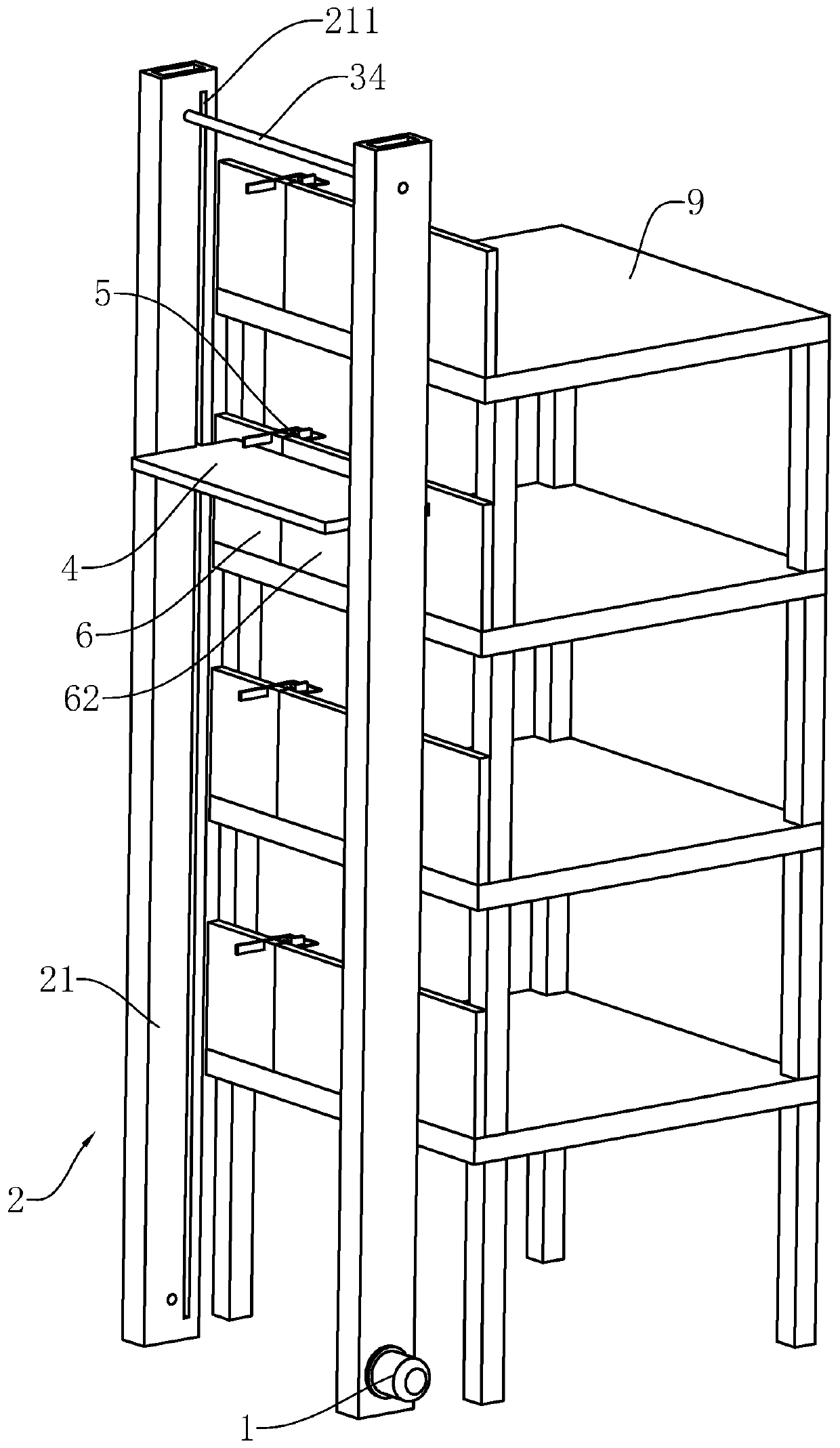

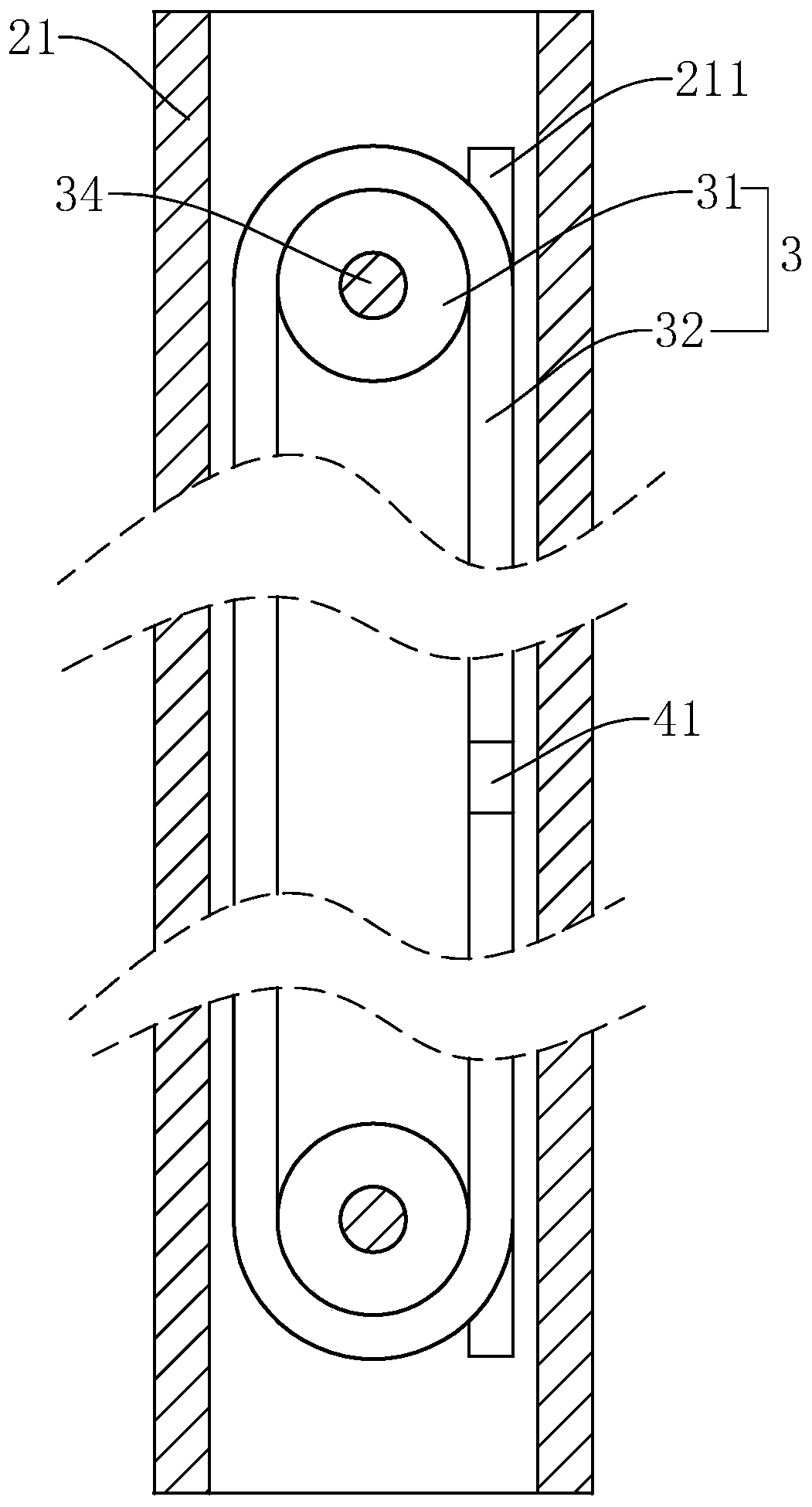

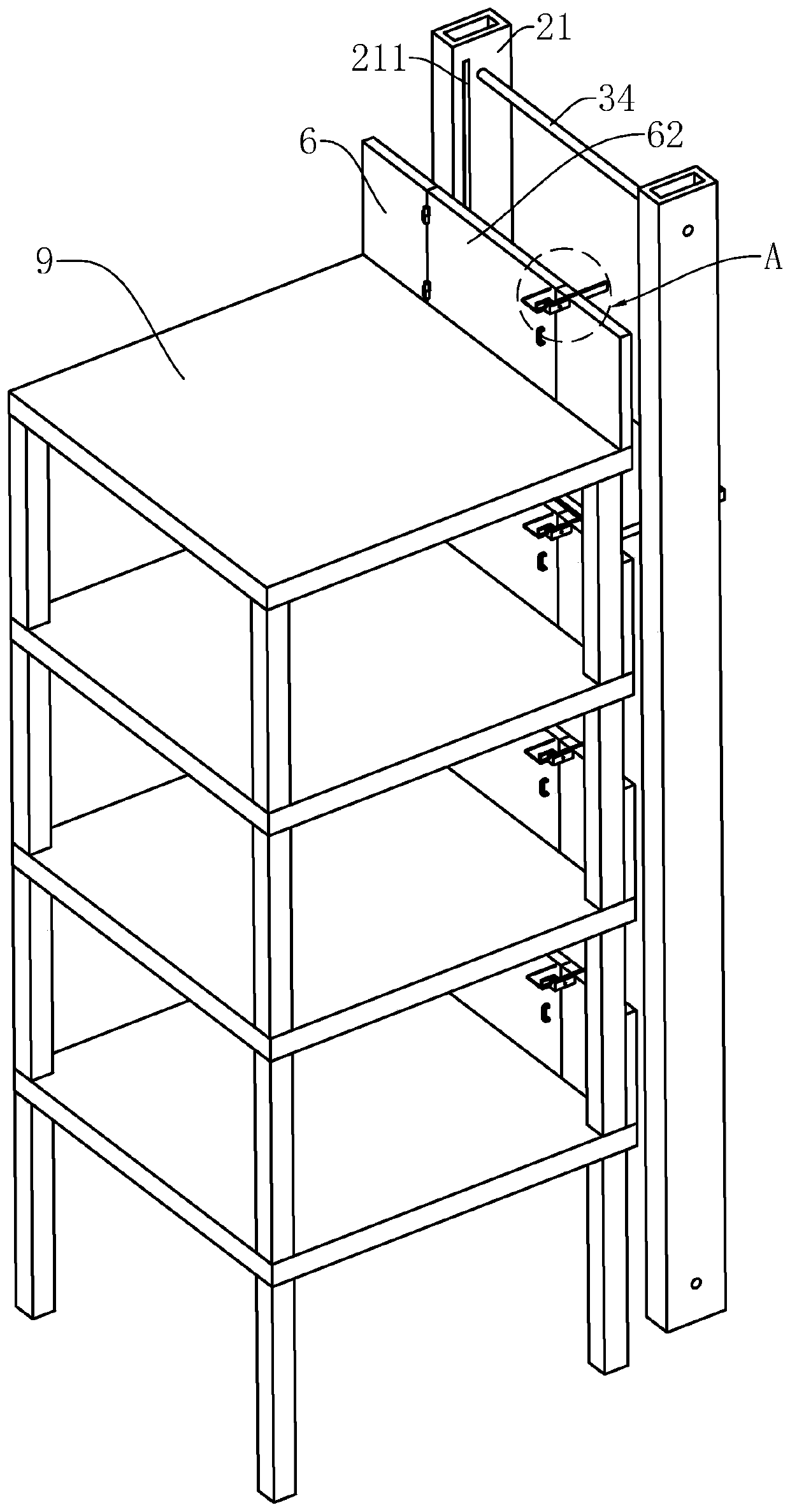

[0026] Such as figure 1 As shown, this embodiment introduces a small-sized material vertical conveyor for building construction, including a motor 1, a mounting bracket 2, and a rail-type vertical lifting device 3 (see figure 2 ) and the loading trolley 4, the mounting bracket 2 is erected vertically on the ground, and the mounting bracket 2 generally needs to be erected across multiple floors as required, the rail-type vertical lifting device 3 is installed on the mounting bracket 2, and the loading trolley 4 On the track-type vertical lifting device 3; the floor 9 of each floor is provided with a guardrail 6, and the guardrail 6 is located between the floor 9 and the loading trolley 4 to play a protective role. Limiting mechanism 5 is all set on column 6. The motor 1 can drive the rail-type vertical lifting device 3 to drive the loading trolley 4 to vertically lift relative to the mounting bracket 2, and stop at the corresponding floor under the limit blocking effect of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com