Preparation method of nickel-tungsten composite base band with cubic texture

A composite base tape and cubic texture technology, applied in the direction of metal rolling, can solve the problems of low mechanical strength, the comprehensive performance of nickel-tungsten alloy is difficult to be effectively taken into account, etc., and achieve the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

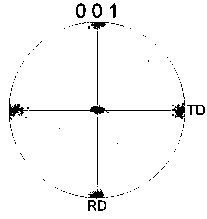

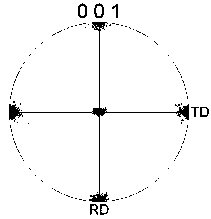

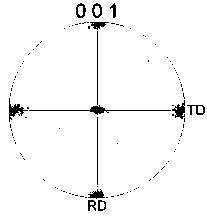

Image

Examples

Example Embodiment

[0016] Example 1

[0017] Using nickel blocks with a purity of 99.99% or more and tungsten blocks with a purity of 99.99% or more as raw materials, the nickel-tungsten alloy ingot is obtained by smelting according to the proportion of W atomic percentage of 10% and the balance being Ni. , The oxygen content in the nickel-tungsten alloy ingot is controlled at 25ppm. The nickel-tungsten alloy ingot is heated to 1230℃ for 30 minutes and then hot rolled, the total deformation is 60%, and the final rolling temperature is controlled above 980℃. The surface of the Ni-10at.%W alloy slab is acid washed to remove the oxide scale, and then the Ni-5at.%W alloy with a thickness of 10μm is electroplated on the lower surface of the hot-rolled plate to obtain Ni-5at.%W / Ni-10at.%W / Ni-5at.%W layered composite plate; the obtained layered composite plate is subjected to diffusion annealing treatment, the specific process: heat preservation at 980°C for 30 minutes, then cold-rolled and deformed to o...

Example Embodiment

[0018] Example 2

[0019] Using nickel blocks with a purity of 99.99% or more and tungsten blocks with a purity of 99.99% or more as raw materials, the nickel-tungsten alloy ingot is obtained by smelting according to the proportion of W atomic percentage of 10% and the balance being Ni. , The oxygen content in the nickel-tungsten alloy ingot is controlled at 20ppm. The nickel-tungsten alloy ingot is heated to 1370℃ for 30 minutes and then hot rolled, the total deformation is 75%, and the final rolling temperature is controlled above 1000℃; The surface of the Ni-10at.%W alloy plate is polished and the oxide scale is electroplated with 10μm thick Ni-5at.%W alloy to obtain Ni-5at.%W / Ni-10at.%W / Ni-5at.%W layered Composite plate; the obtained layered composite plate is subjected to diffusion annealing treatment, the specific process: 1050 ℃ heat preservation for 30 minutes, and then cold-rolled deformation to obtain a cold-rolled composite strip, the total deformation is 98%, the defo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap