A Simulation System for the Roof Failure Process of Layered Salt Rock after Water Solution Mining

A simulation system, salt rock technology, applied in the field of simulation system of the roof failure process after layered salt rock water solution mining, can solve the problems of large span roof of horizontal cavity, lack of planning, scrapped storage, etc., to ensure the overall strength and Airtightness, convenient measurement and observation, and convenient repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

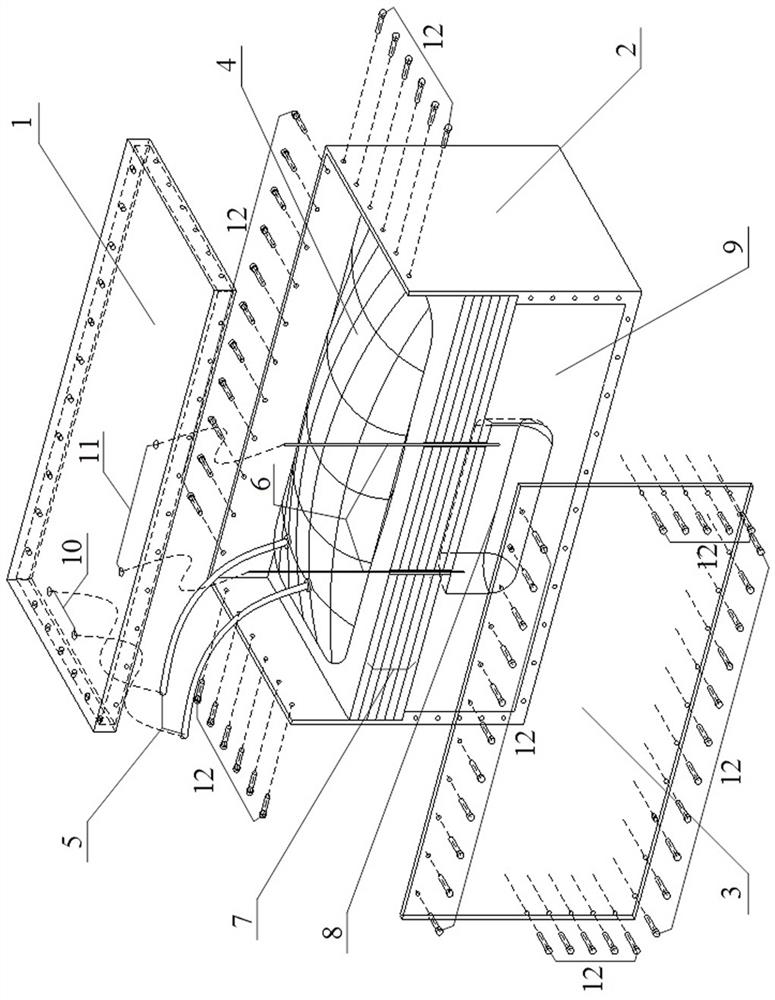

[0023] as attached figure 1 Shown is a simulation system for the roof failure process after water solution mining of layered salt rock, which includes a cover plate 1, a material box 2, a front panel 3, a pressure-resistant water bag 4, a cavity water injection pipe 6, and a simulated overlying rock layer 7, Salt rock 9 and fastening bolt 12.

[0024] as attached figure 1 As shown, the cover plate 1 is in the shape of a box cover with eaves all around, and its size is just to accommodate the material box and the front panel. It is made of aluminum alloy. The four eaves are opened with equidistant round holes and tapped. 2 and the front panel 3 are fixed. At the same time, two pressure-resistant water bag water injection holes 10 and two cavity water injection pipe holes 11 are reserved at the corresponding positions of the cover plate to ensure smooth water injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com