Supporting device for hydraulic pipeline vibration test of aero-engine

A technology for aero-engine and vibration testing, applied in vibration testing, fluid pressure actuating devices, measuring devices, etc., can solve problems such as inability to simulate hydraulic system tests, difficult to explore, and inability to detect multi-space bending angle pipeline vibration signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

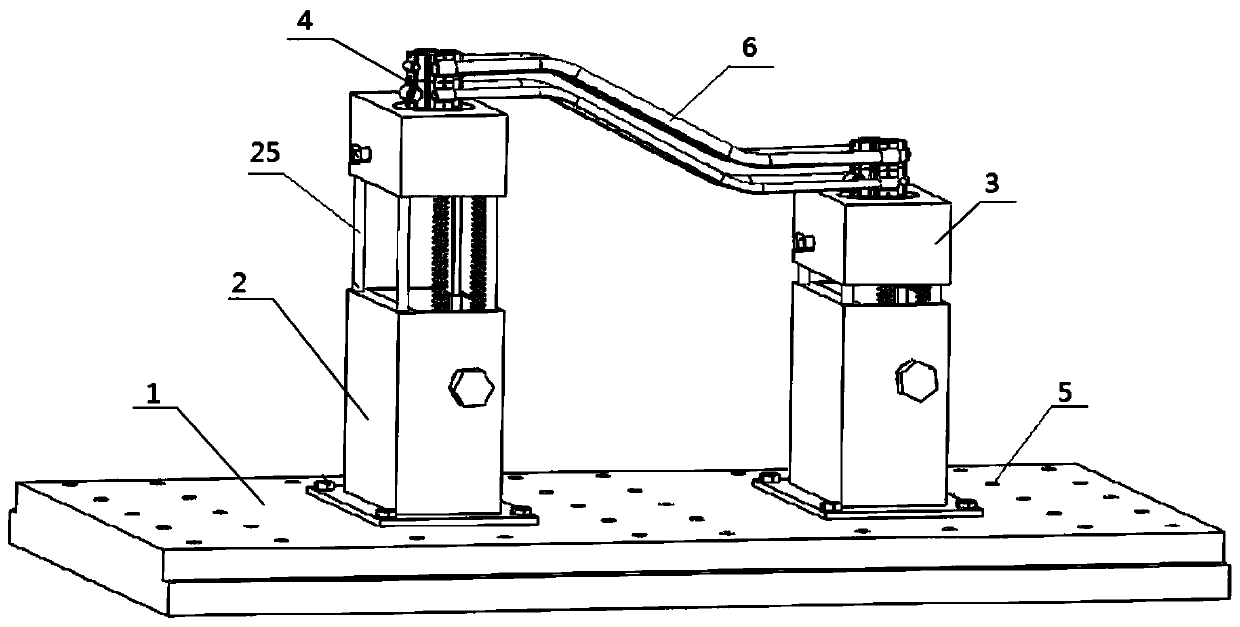

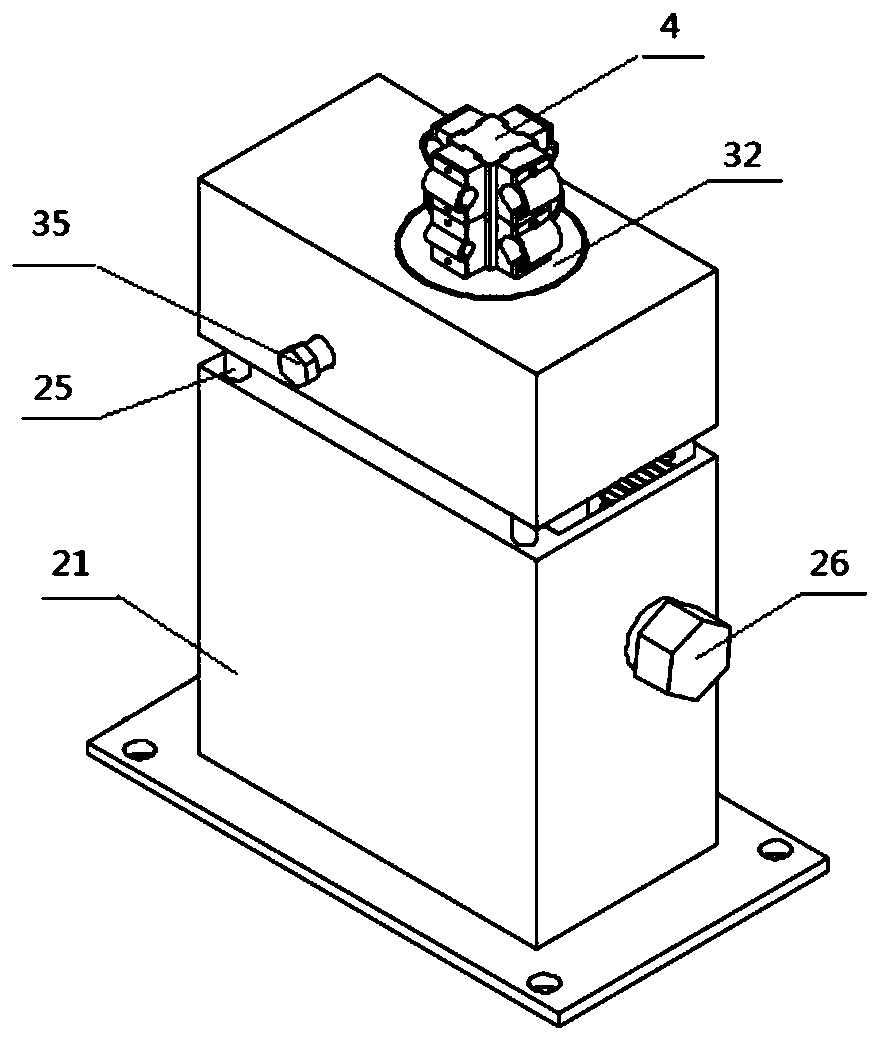

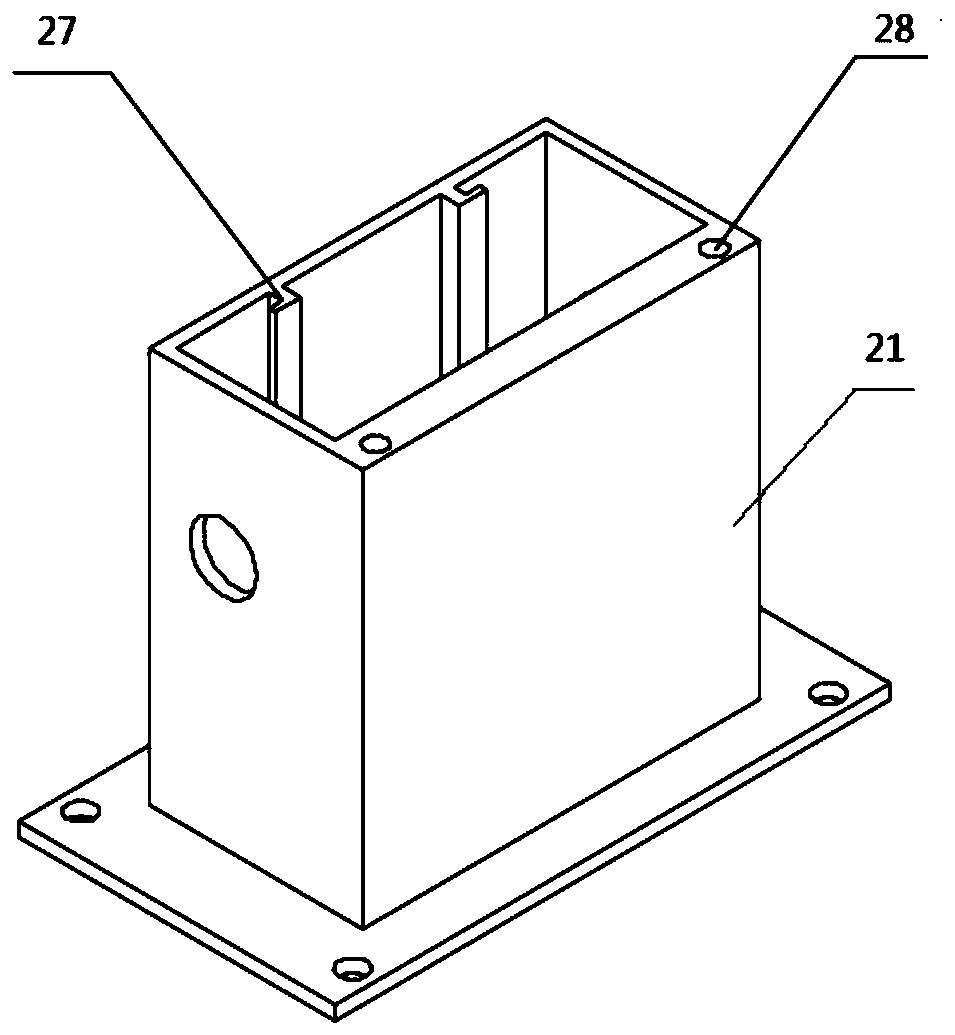

[0025] Such as figure 1 , for the use of the supporting device for the vibration test of the hydraulic pipeline of the aero-engine, select two lifting bases 2 according to the length and space shape of the pipeline under test 6, and fix the two lifting bases 2 on the bolt holes of the support base 1 5, then connect the tested pipeline 6 with the oil pump and fix it on the pipe clamp slider 42 of the corresponding aperture, adjust the height of the lifting base 2, adjust the angle of the rotating device 3, realize the support of the tested pipeline 6, and carry out pipeline Vibration test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com