A high-precision on-line rapid measurement device and measurement method for the thickness of an aluminum substrate

A measuring device and aluminum substrate technology, which is applied in the fields of microelectronics, intelligent manufacturing, mechatronics, and electronic information, can solve the problems of mixing materials and indistinguishable visual inspection methods, and achieve high test accuracy, fast measurement speed, and device compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

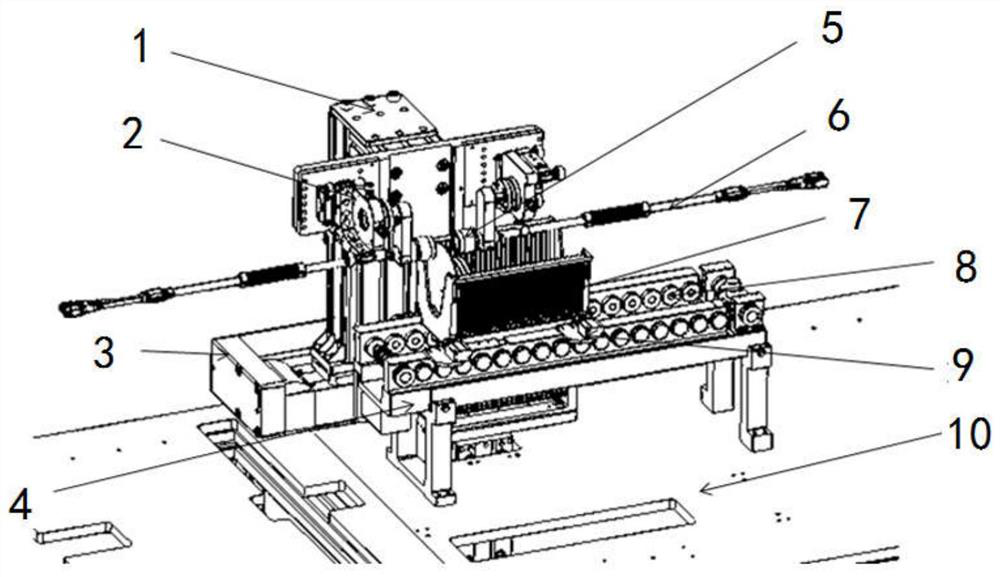

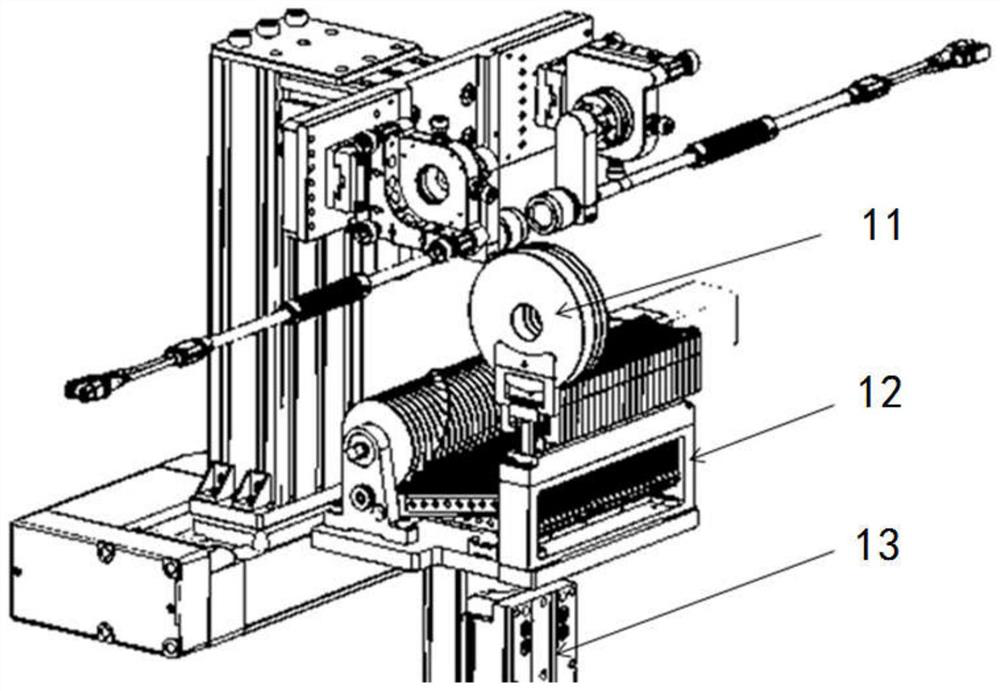

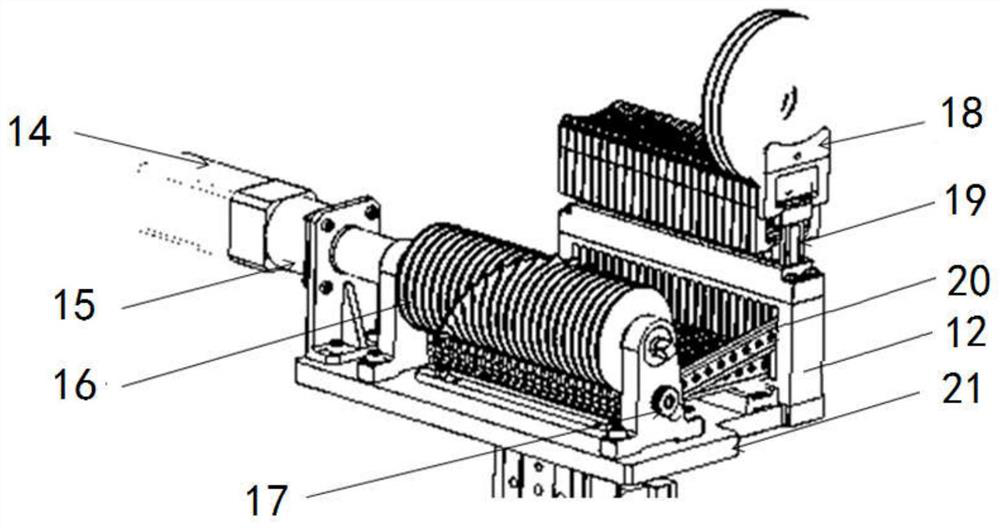

[0031] Such as figure 1 combine figure 2 As shown, a high-precision on-line fast measuring device for aluminum substrate thickness of the present invention includes a horizontal driving device 3, a vertical driving device 13 and a conveyor rail 4 installed on the base platform 10, the horizontal driving device 3 and the vertical driving device Device 13 is directly driven by a servo electric cylinder. The transmission rail 4 is located at the side of the horizontal drive device 3, and the vertical drive device 13 is located between the horizontal drive device 3 and the transmission rail 4; the horizontal drive device 3 is equipped with a support 1, and two attitude adjustment devices 2 are installed on the support 1, each A laser emitting head 5 is respectively installed on each att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com