Phase winding

A technology of phase winding and combined coil, which is applied in the field of phase winding, can solve the problems of inconsistent height, appearance, and form of the bending part, poor consistency of the torsion direction of the welding end, and the failure of the bending part to be consistent, etc., to shorten the spanning distance , Avoid mutual entanglement, simple connection and simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: as Figure 5-14 As shown, the purpose of this embodiment is to provide a phase winding, a stator 100 and a motor, the motor includes a motor and a generator, and also includes a unidirectional motor and a multi-phase motor.

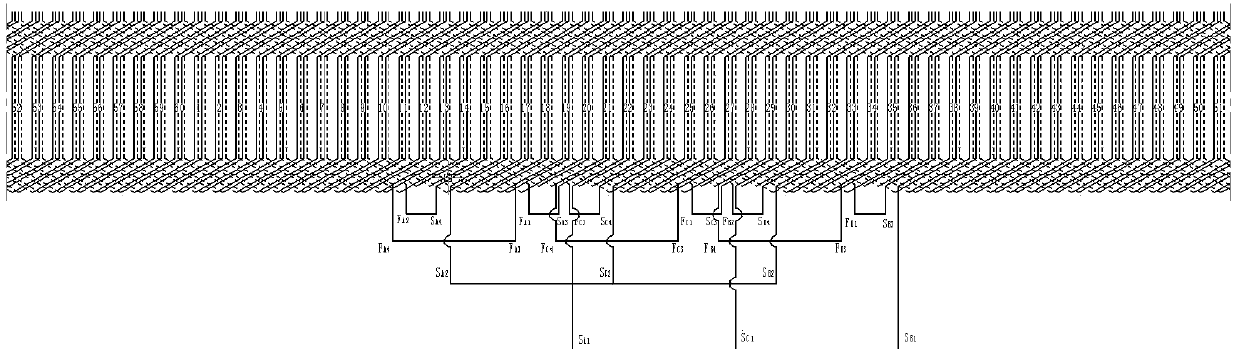

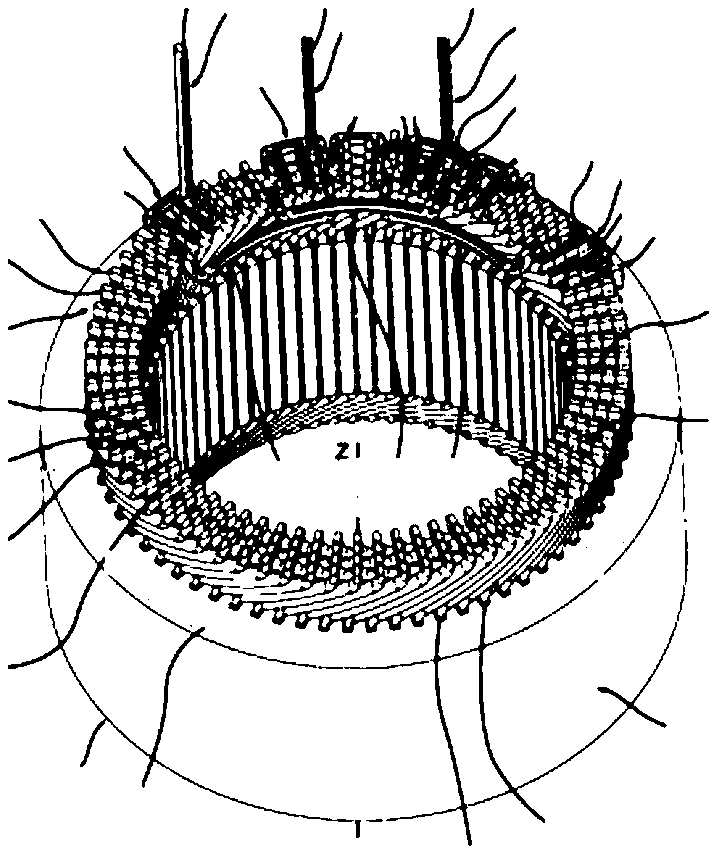

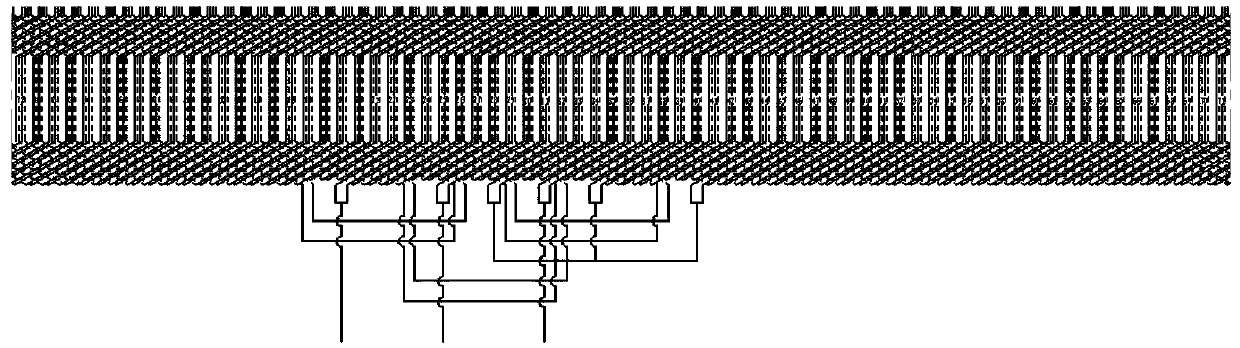

[0068] Wherein, the stator includes a stator core 1, and the stator core includes a substantially cylindrical main body 11, and a plurality of stator core slots opening inwards are provided along the circumference of the inner ring of the stator core. 12, that is to say, the opening of the stator core slot faces the central axis (z1-z2) of the stator core, one end of the stator core slot is the insertion side 13, and the other end is the connection side 14, in the A unidirectional or multi-phase winding 10 is arranged in the slot of the stator core, and each phase winding 2 is formed by overlapping and radially displacing more than one coil ring 3 along the circumferential direction of the stator core, and each coil ring 3 is formed b...

Embodiment 2

[0088] Embodiment 2: as Figure 5 , 6 , 15-24, the purpose of this embodiment is to provide a phase winding, a stator and a motor, the motor includes a motor and a generator, and also includes a unidirectional motor and a multi-phase motor.

[0089] Wherein, the stator includes a stator core 1, and the stator core includes a substantially cylindrical main body 11, and a plurality of stator core slots opening inwards are provided along the circumference of the inner ring of the stator core. 12, that is to say, the opening of the stator core slot faces the central axis (z1-z2) of the stator core, one end of the stator core slot is the insertion side 13, and the other end is the connection side 14, in the A three-phase winding 10 is arranged in the slot of the stator core, and each phase winding 2 is formed by overlapping and radially displacing more than one coil ring 3 along the circumferential direction of the stator core, and each coil ring is formed by a plurality of combin...

Embodiment 3

[0111] Embodiment 3: as Figure 25-27 As shown, this embodiment is an improvement made on the basis of Embodiment 1 and Embodiment 2. In this embodiment, the phase winding can be composed of more than one C2 type coil ring and / or more than one Cn type coil ring along the stator The iron cores are overlapped or arranged in dislocation in the circumferential direction; wherein, the C2-type coil ring is formed by connecting a plurality of combined coils C2 end to end along the circumferential direction of the stator core; the Cn-type coil ring is formed by a plurality of combined coils Cn along the stator iron core. The core is formed by end-to-end connection in the circumferential direction.

[0112] For example, when A=8, two turns of C2-type coil rings can be arranged in overlapping or dislocation in the circumferential direction of the stator core; Coil ring and 1 turn of C3 type coil ring constitute, and so on.

[0113] In this embodiment, it is shown that when A=8, a stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com