Heat transfer plate and plate pack for a heat exchanger comprising a plurality of such heat transfer plates

A technology of heat transfer plate and section, applied in the field of heat transfer plate and its design, can solve the problems of limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

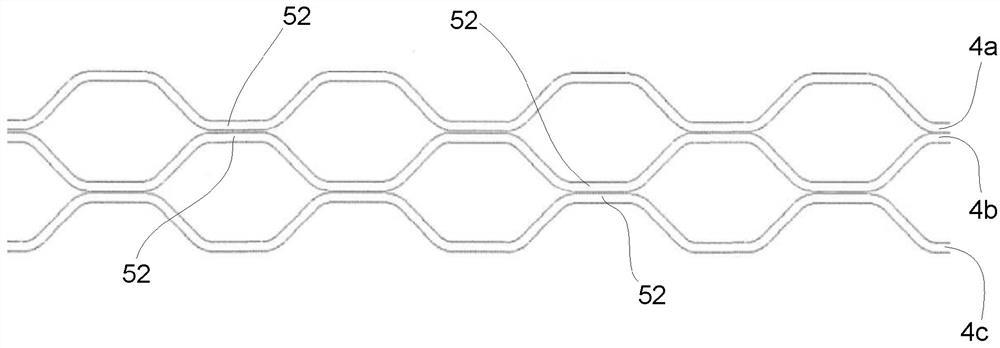

[0064] refer to figure 1 , shows a plate pack 2 for a gasketed plate heat exchanger comprising a plurality of heat transfer plates. All heat transfer plates are of the same type. discussed further below Figures 4a-4d , respectively show the first heat transfer plate 4a, the second heat transfer plate 4b and the third heat transfer plate 4c among the plurality of heat transfer plates. exist figure 1 Also visible in the first heat transfer plate 4a. The design and function of gasketed plate heat exchangers are well known and are discussed by way of introduction and therefore will not be described in detail here.

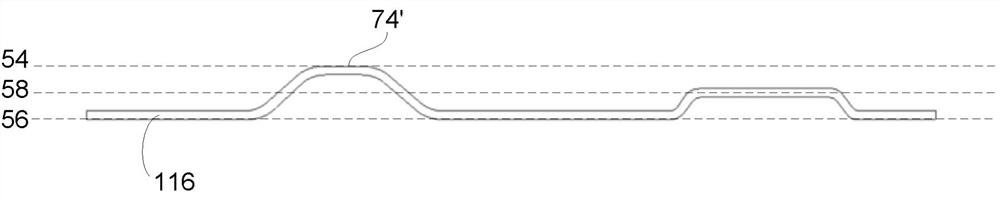

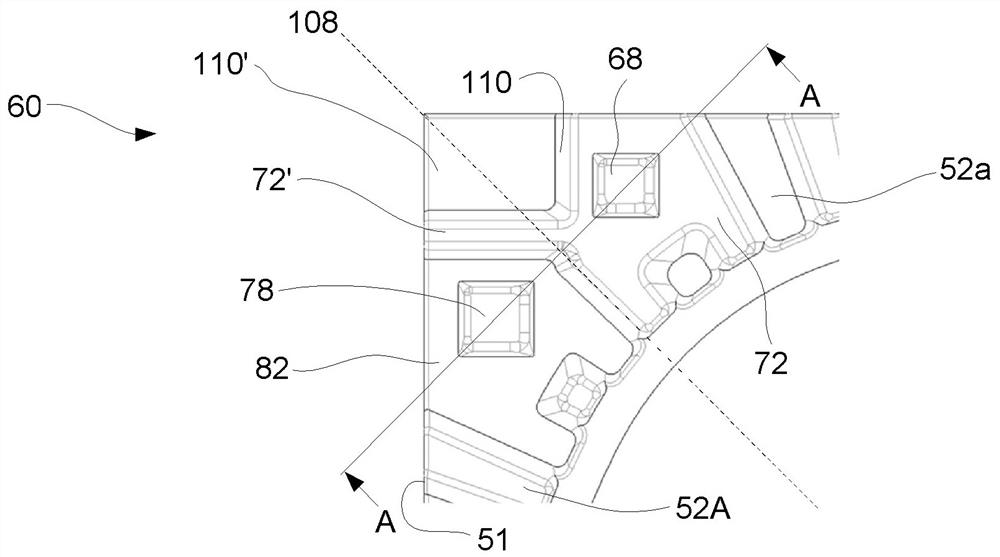

[0065] will now refer to figure 1 , 2a - 2d and 3a-3g further describe the heat transfer plate 4a, figure 1 , 2a - 2d and 3a-3g show the heat transfer plate and parts and sections of the heat transfer plate, respectively. The heat transfer plate 4a is a substantially rectangular stainless steel plate having opposite first sides 6 and second sides 8 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com