Series self-adaptive elastic band device for improving launching safety of non-rib rifling artillery

An adaptive and safe technology, applied in the direction of offensive equipment, weapon accessories, barrels, etc., can solve the problems of projectile jammed launch safety, belt structure damage, large torsion force, etc., to avoid damage and functional failure, and to achieve safety The effect of launching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] The invention proposes a segmented series self-adaptive belt device for improving the firing safety of non-equal rifled guns, which includes multiple thinner belt rings and colloid with lower peeling strength.

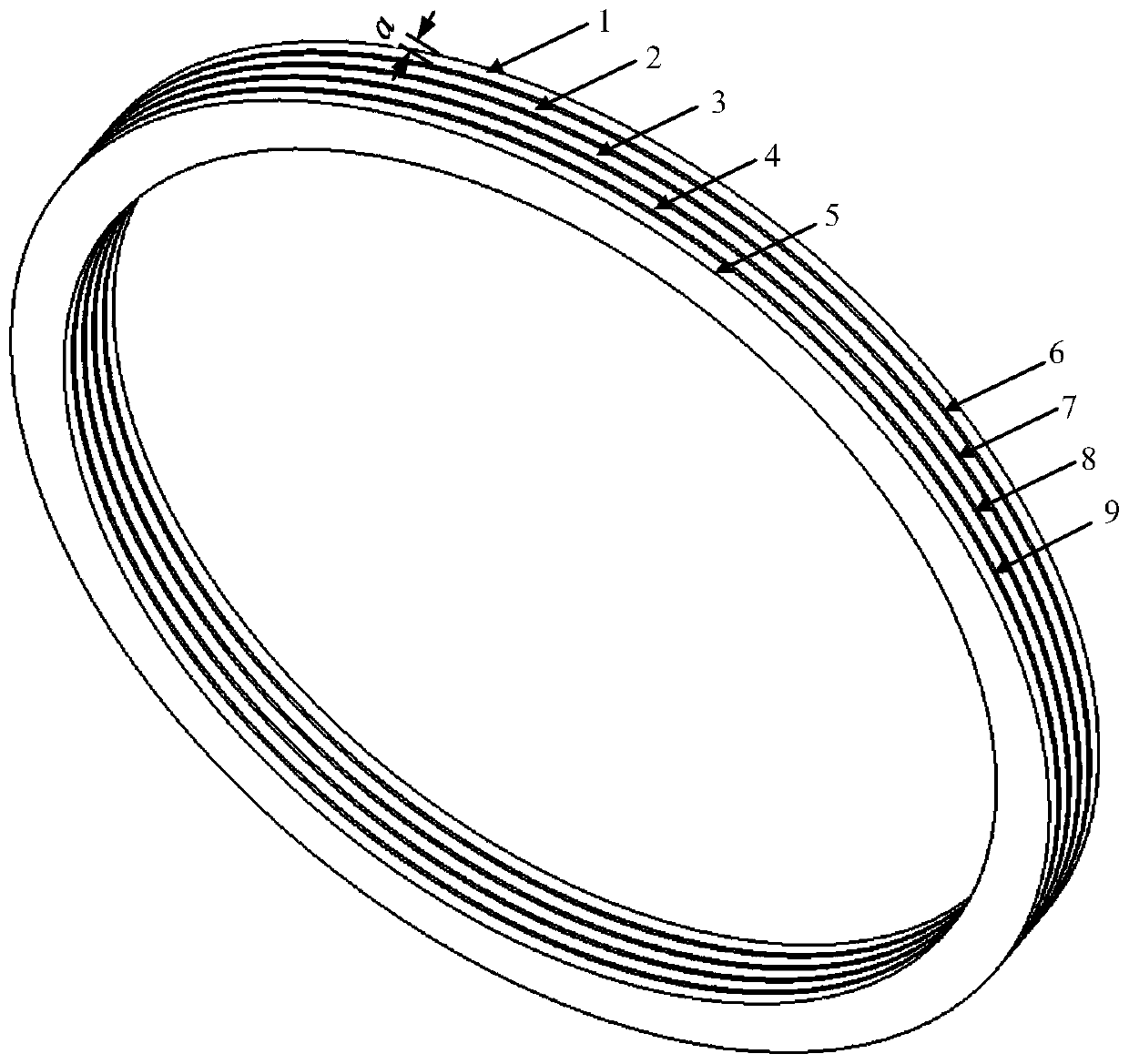

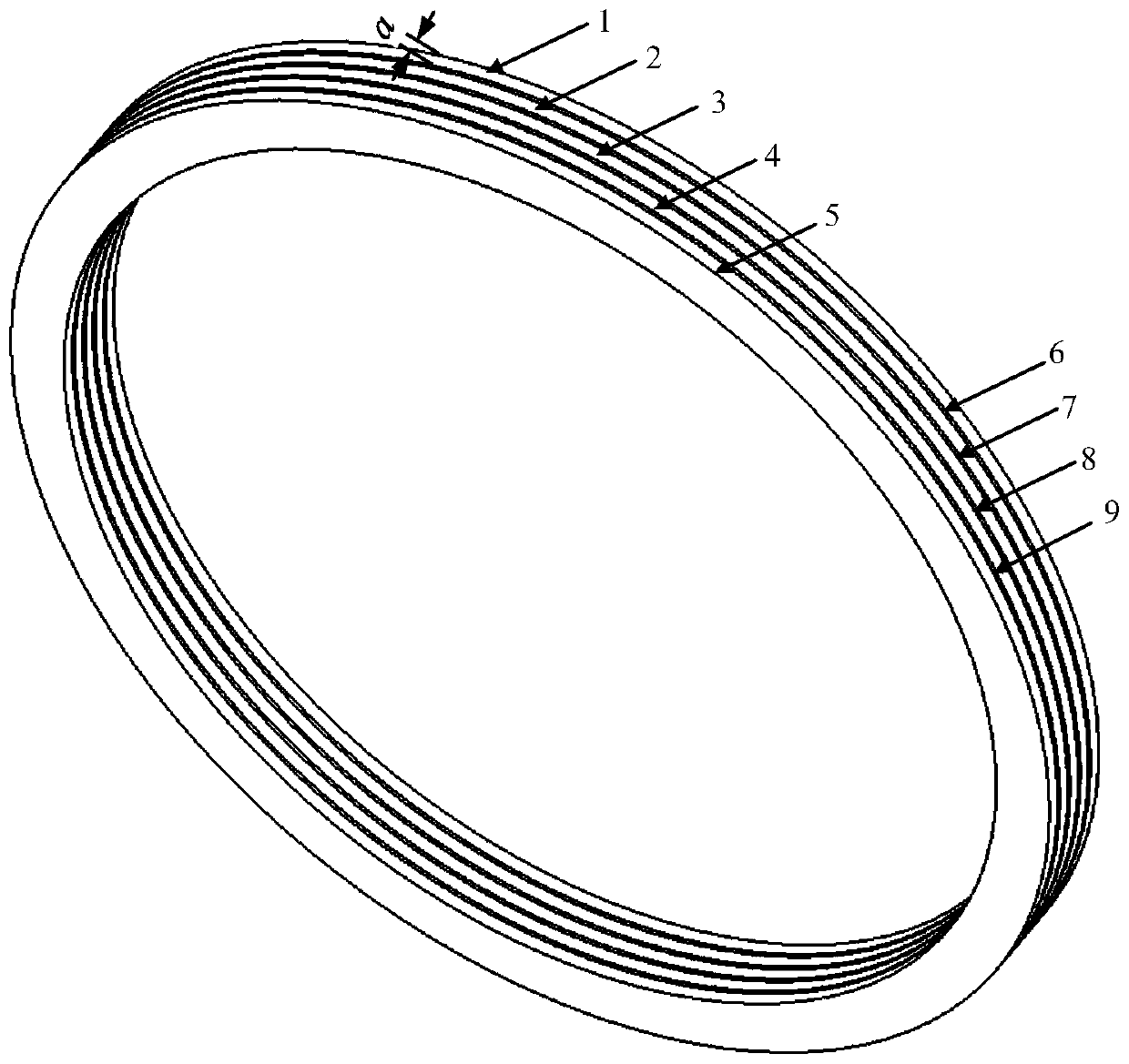

[0018] Such as figure 1 , five elastic belt rings with small thickness (elastic belt ring Ⅰ1, elastic belt ring Ⅱ2, elastic belt ring Ⅲ3, elastic belt ring Ⅳ4, elastic belt ring Ⅴ5), through colloid (colloid Ⅰ6, colloid Ⅱ7, colloid Ⅲ8, colloid Ⅳ9) Fix the initial relative position.

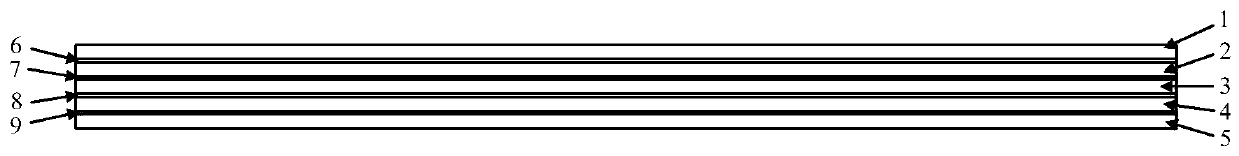

[0019] The connection between the thinner elastic belt loops is as follows figure 2 shown. figure 2 The relative position of the elastic belt ring I1 and the elastic belt ring II2 is fixed by the colloid I6, and the connection relationship between the other elastic belt rings and the colloid is similar.

[0020] As the belt moves toward the muzzle, when the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com