MEMS loudspeaker and manufacturing method thereof

A speaker and driver technology, applied in electrostatic transducer speakers, microphones, sensors, etc., can solve the problems of large vibration amplitude of the diaphragm, low sound output of the speaker, and small vibration amplitude of the surrounding parts, so as to improve the sound output and improve the sound. output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

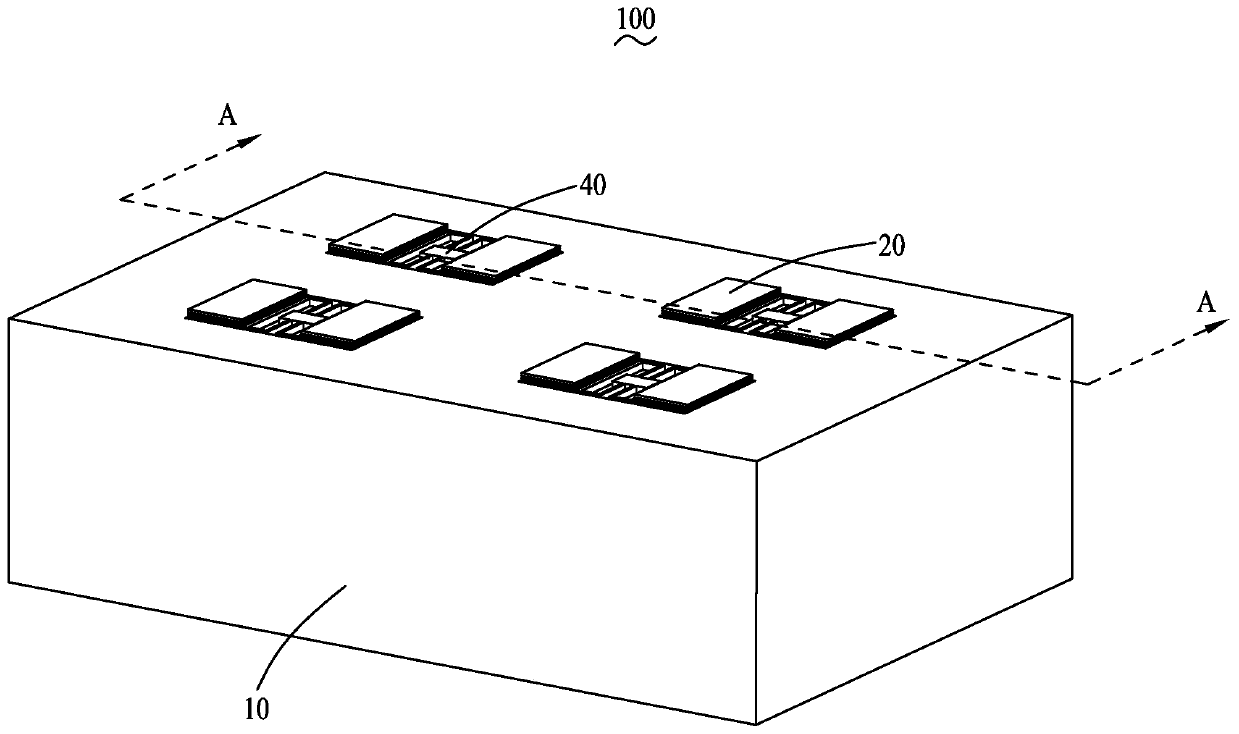

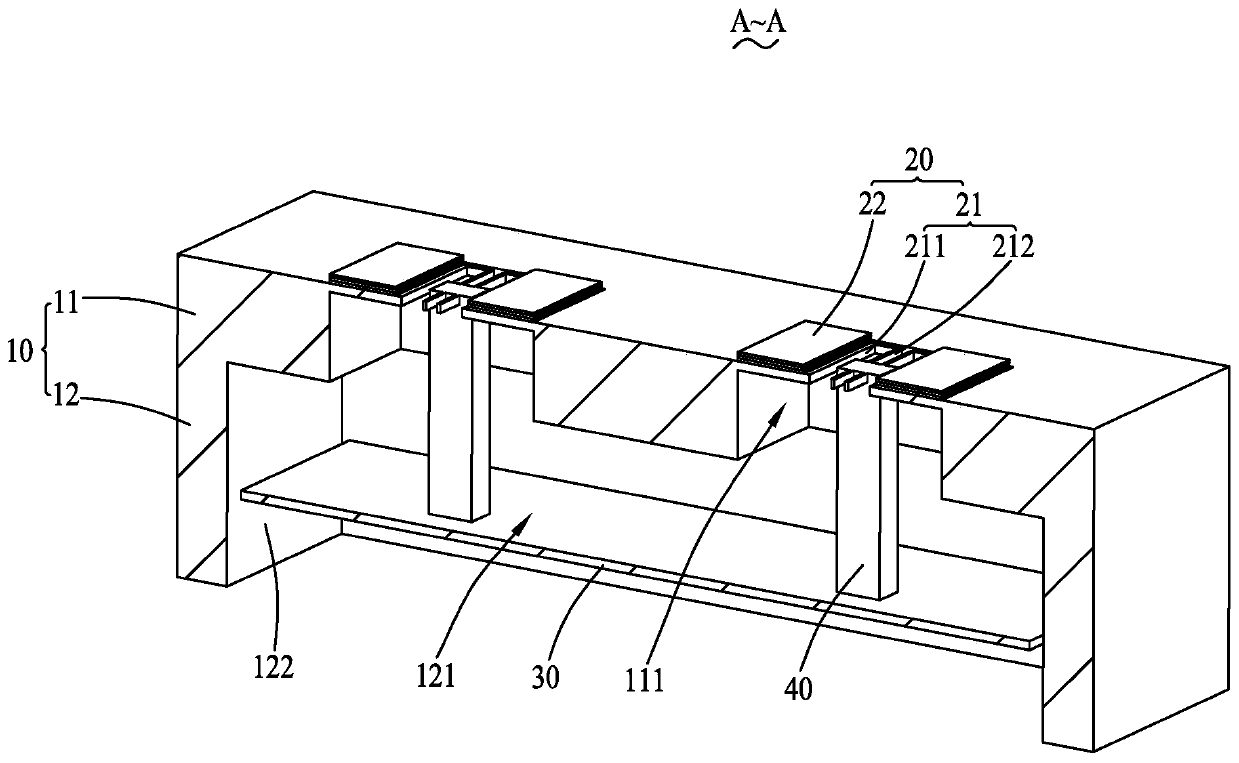

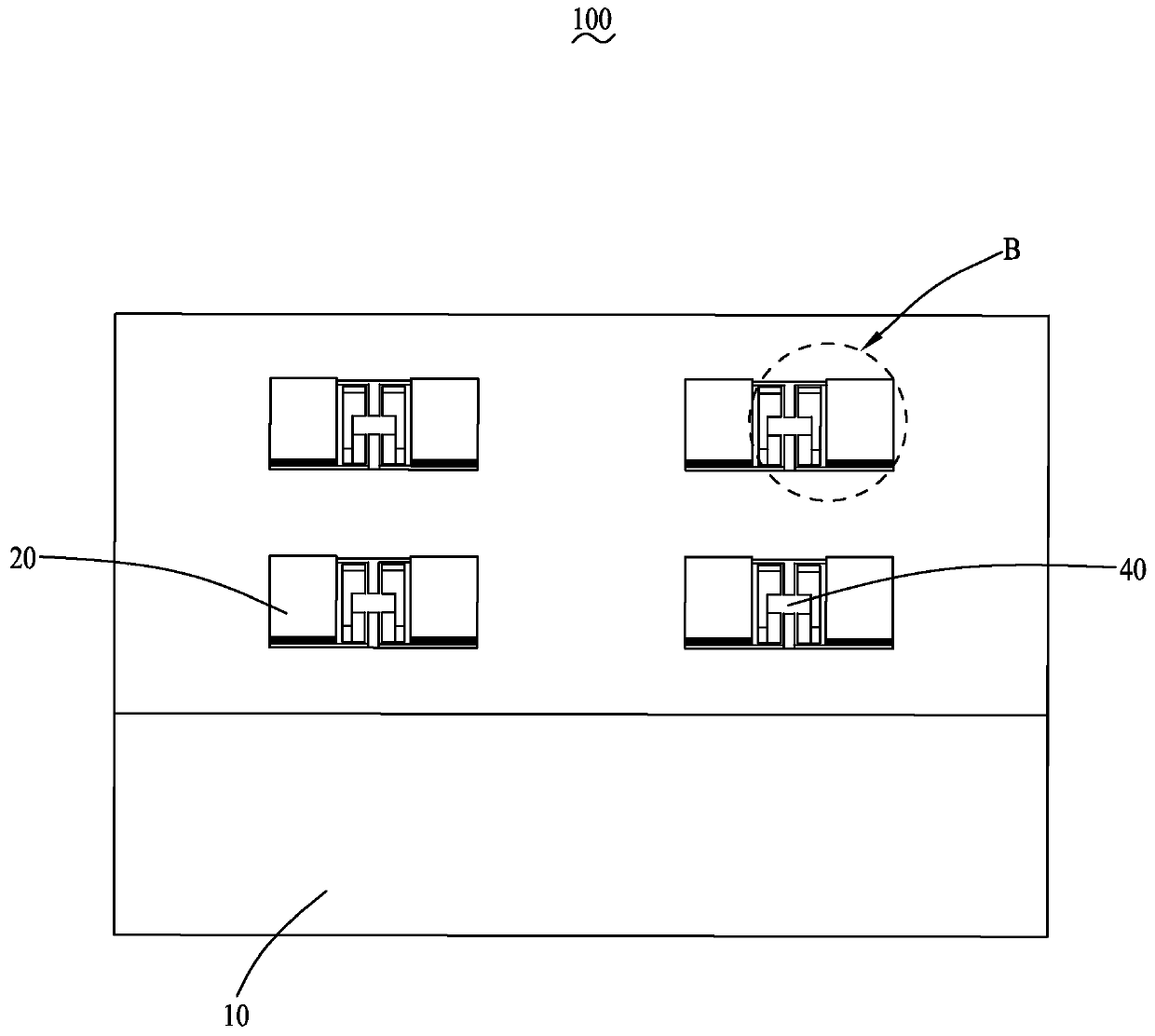

[0040] see Figure 1 to Figure 4, a MEMS speaker 100 provided according to an embodiment of the present invention includes a base 10, a vibrating assembly 20, a diaphragm 30, and a connecting rod 40. The base 10 includes a base 11 and a support seat 12, and the support base 12 is formed from one side of the base 11 Extending away from the base 11, the base 11 is provided with a first cavity 111 along its thickness direction, which is also the extension direction of the support seat 12. Body 111 communicates with the second cavity 121, the inner diameter of the first cavity 111 along the direction perpendicular to the thickness of the base 11 is smaller than the second cavity 121, that is, the profile of the first cavity 111 is smaller than the second cavity 121, the vibration The component is fixed on the base 11 and covers at least part of the first cavity 111, one end of the connecting rod 40 is connected to the vibrating component 20, and the other end extends through the f...

Embodiment 2

[0075] see Figure 6 Compared with the MEMS speaker 100 provided in Embodiment 1, the MEMS speaker 200 provided in this embodiment is: the base 11' of this embodiment is provided with three first cavities 111' at intervals, and the three first cavities 111' are along the The MEMS speakers 200 are equally spaced along the length direction. It can be understood that the number of first cavities 111 ′ is not limited to three, for example, one, two or other numbers of multiples are also possible.

Embodiment 3

[0077] see Figure 7 Compared with the MEMS speaker 100 provided by Embodiment 1, the MEMS speaker 300 provided in this embodiment is cylindrical, and the vibration member 21 "is a cantilever beam form, and three The first cavities 111", the three first cavities 111" are equally spaced along the circumference of the base 11", and the angle between any two adjacent cantilever beams is 120°. It can be understood that the first The number of a cavity 111" is not limited to three, for example, one, two or other numbers of multiples are also possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com