Energy effecient blow molder control

A molding machine, controller technology, applied in the direction of digital control, electrical program control, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

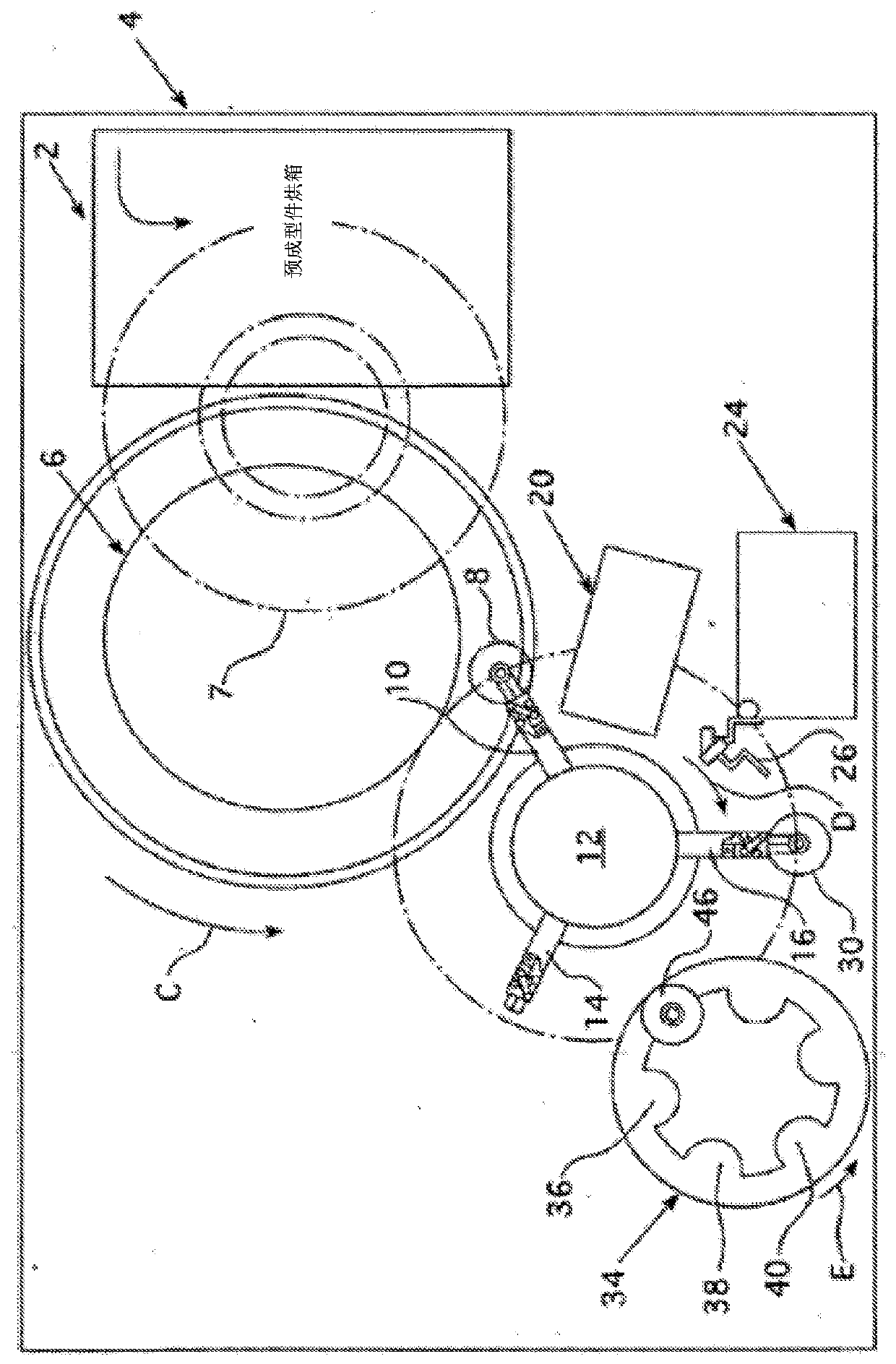

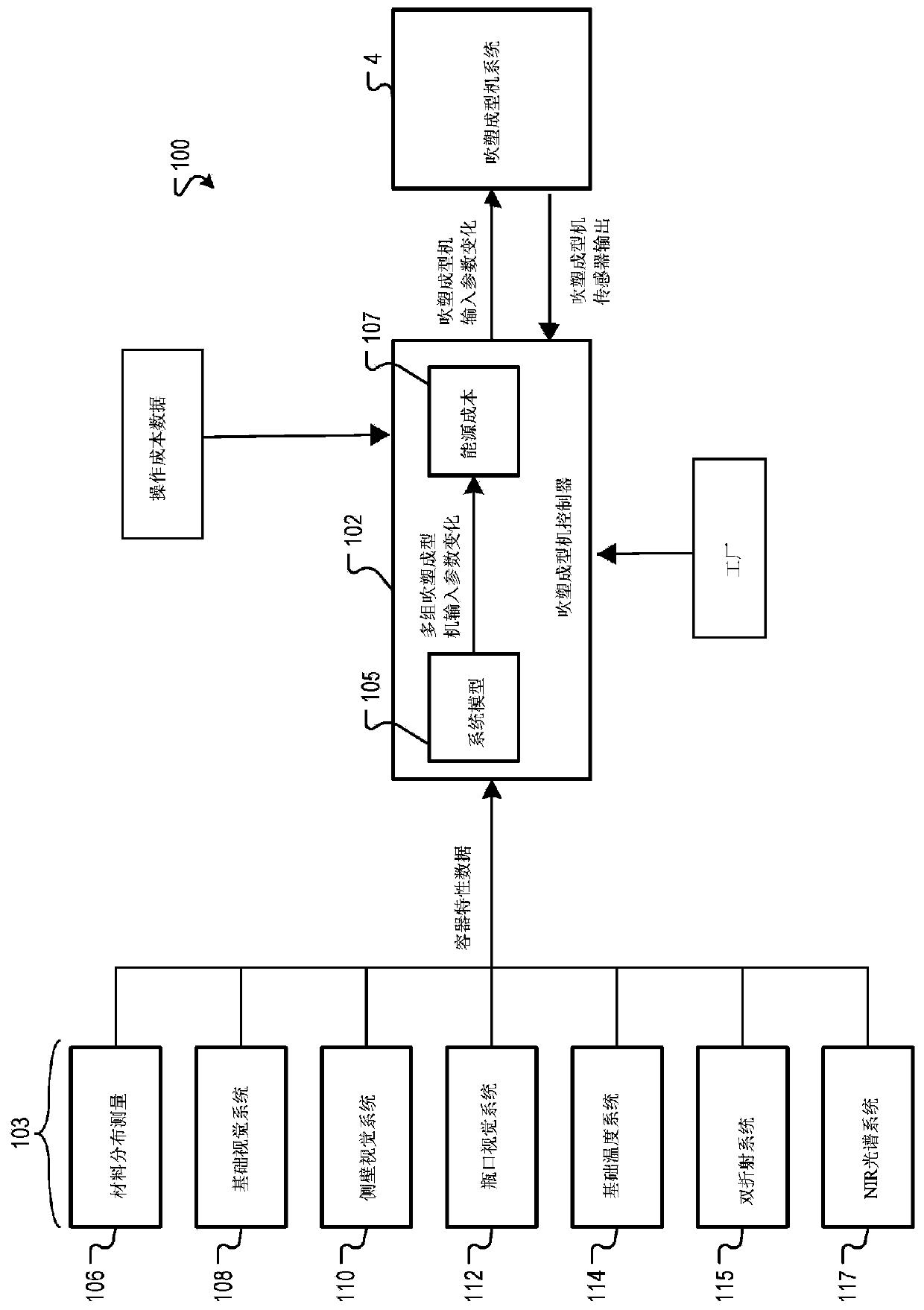

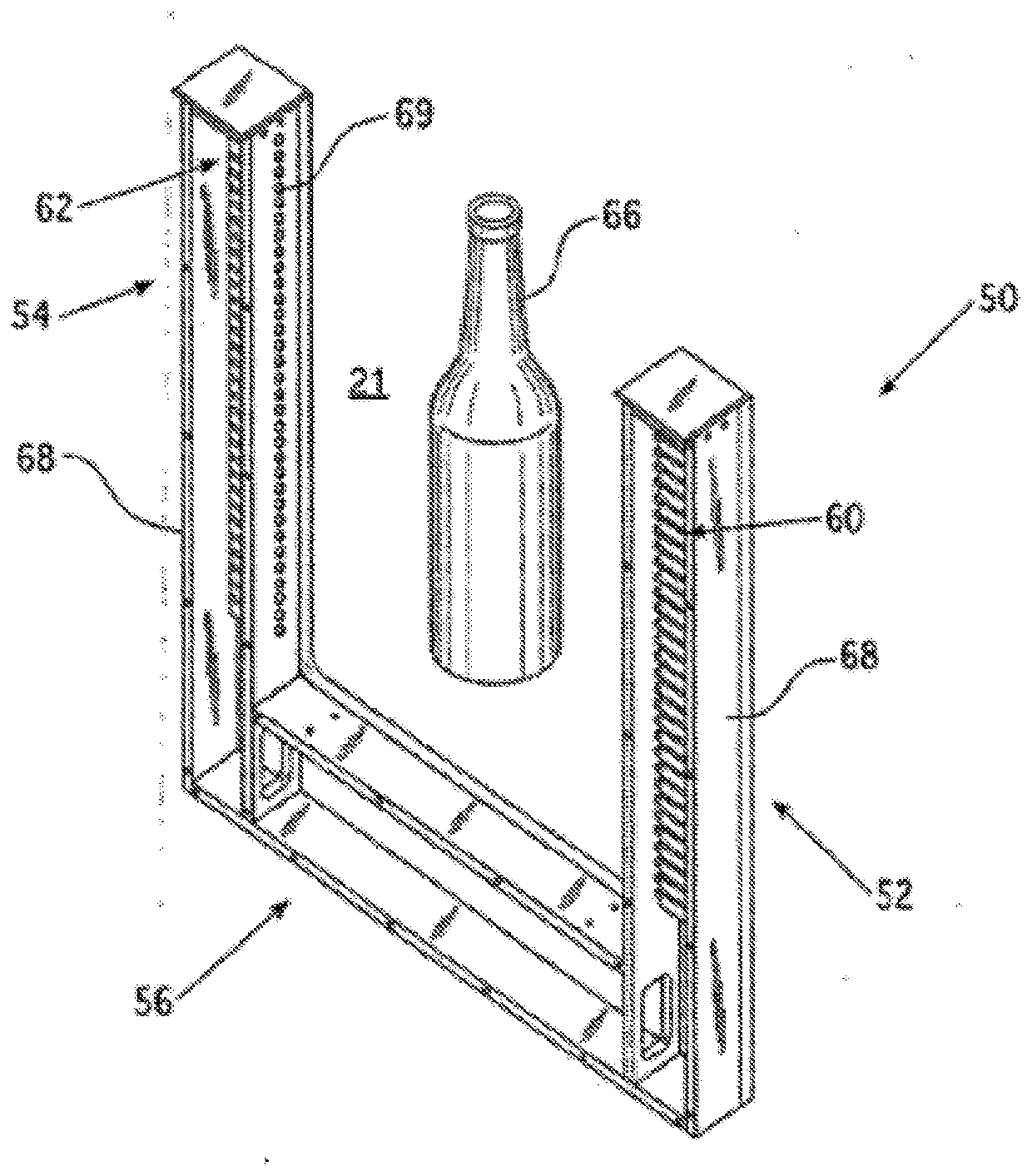

[0027] Various embodiments described herein relate to systems and methods for improving the efficiency (eg, energy efficiency) of blow molding machine controllers. The blow molding machine controller executes a system model that correlates changes in the input parameters of the blow molding machine with the characteristics of the container produced by the blow molding machine. In one embodiment, the operating cost module of the blow molding machine controller evaluates changes in multiple sets of input parameters generated by the system model based on energy and / or other similar costs. The blow molding machine controller implements a set of blow molding machine input parameter changes, and the set of blow molding machine input parameter changes balance effectiveness and energy cost efficiency.

[0028] Operators of blow molding machines want to reduce their operating costs and at the same time manage the environment more effectively. Operators and manufacturers of blow molding m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap