Manufacturing method of metal mosaic side shielding connection in non-metallic composite material

A metal inlay and composite material technology, applied in bumpers, armor, protective equipment, etc., can solve problems such as inability to realize modular design ideas, difficult protection capabilities, and poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The present invention will be further described below in conjunction with accompanying drawing:

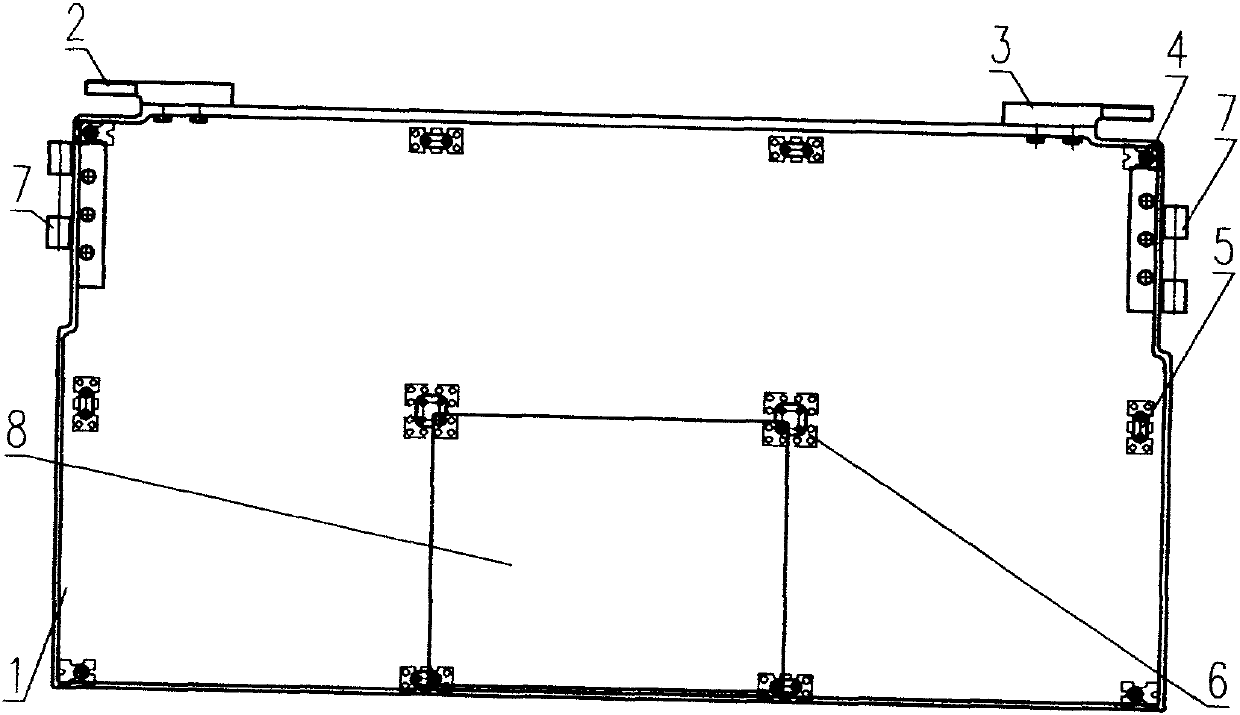

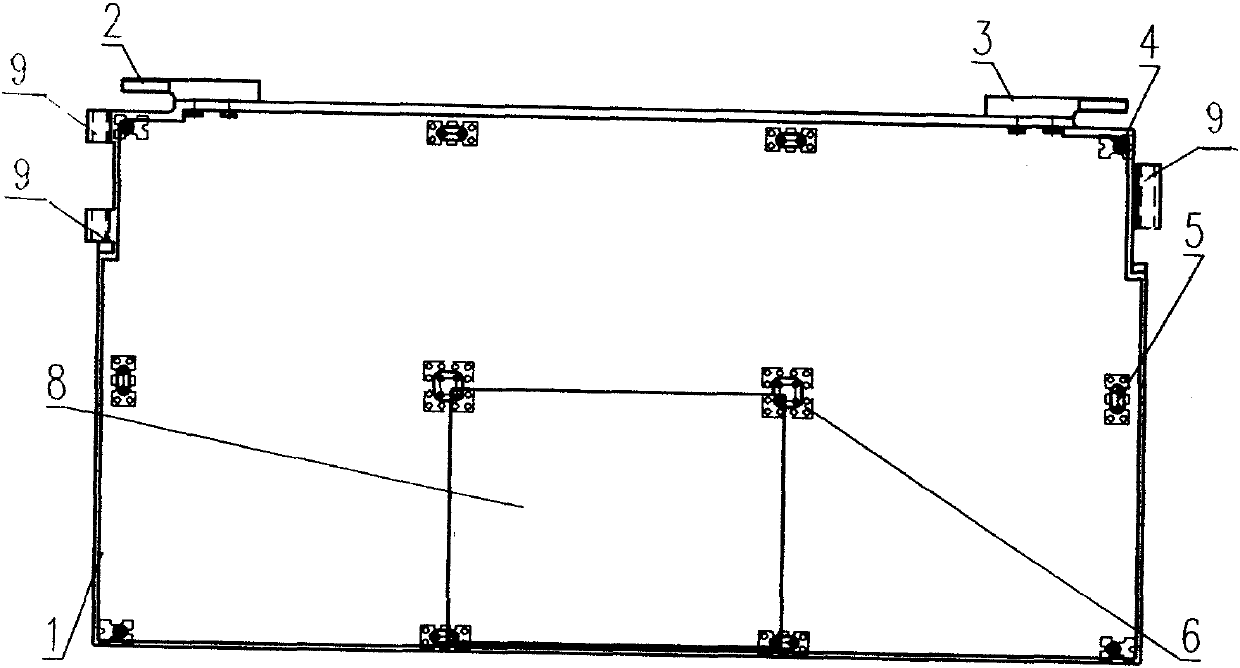

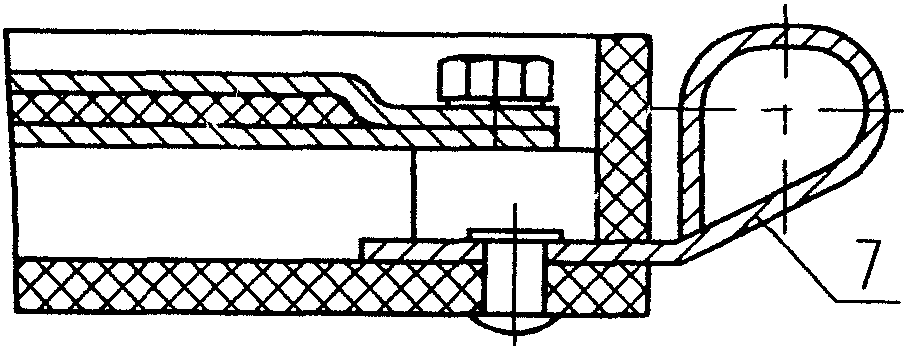

[0025] Refer to attached figure 1 , 2 , 3, 4, 5, 6, 7:

[0026] (1) Modified vinyl ester resin is used as the matrix material, and high-strength glass fiber is used as the reinforcing material. Manufactured by the VARI process, the metal inlays 4, 5, 6 are embedded simultaneously during the process, and one end of the metal inlays 4, 5, 6 is exposed to form the shielding plate 1.

[0027] (2) Metal inlaid parts 4, 5, 6 structure, on the 2 ~ 2.5mm thick plate, welded with threaded hole attachment seat, slot (hole) on the plate, increase metal inlaid parts 4, 5, 6 and non-metallic Composite bonding, which plays a major role in the invention,

[0028] (3) There are two schemes A and B for the connection between the shielding plates 1:

[0029] A is: slot on the shielding plate 1, fix the slotted connecting ear 7 on the shielding plate 1 with bolts or rivets, one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com